Metal pipeline spiral part rust removal device

A metal pipe and helix technology, which is applied in the field of metal pipe helix derusting devices, can solve problems such as affecting subsequent use, difficulty in screwing metal pipes, and incomplete derusting of the helix of metal pipes, etc., so as to improve the effect and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

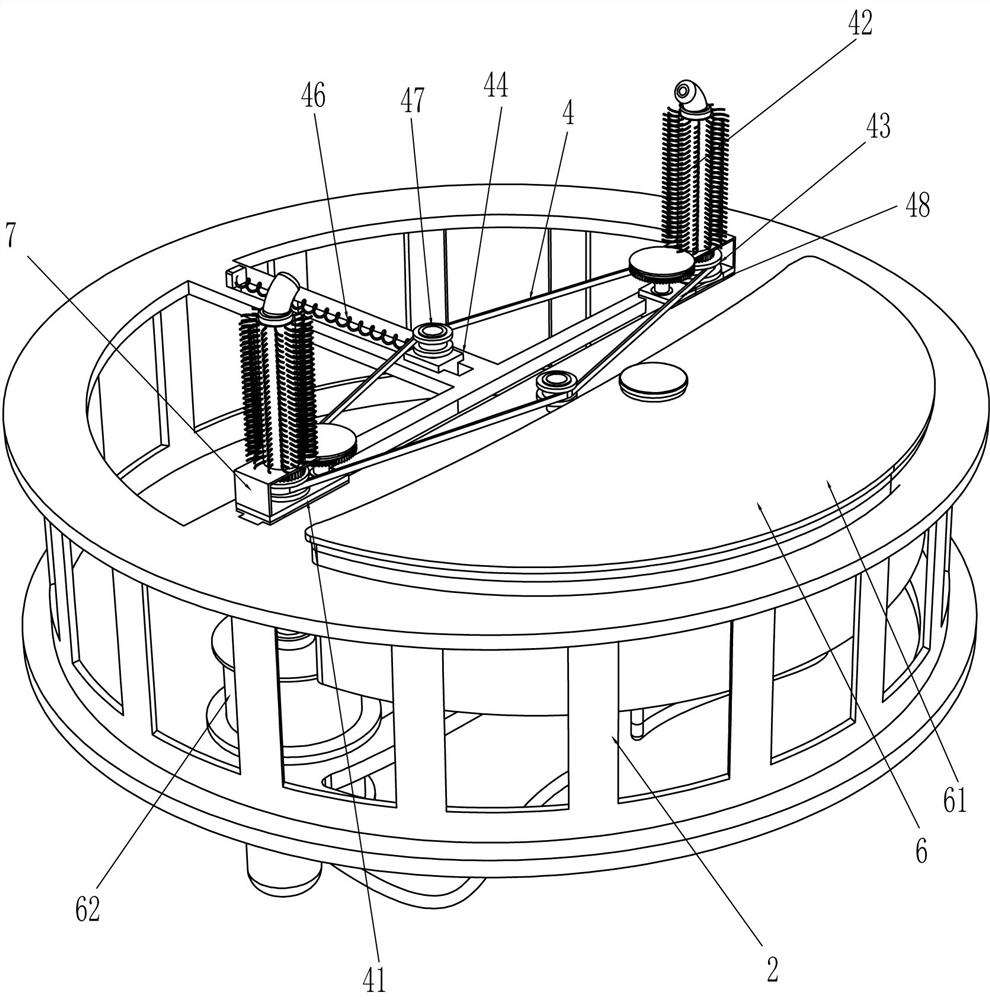

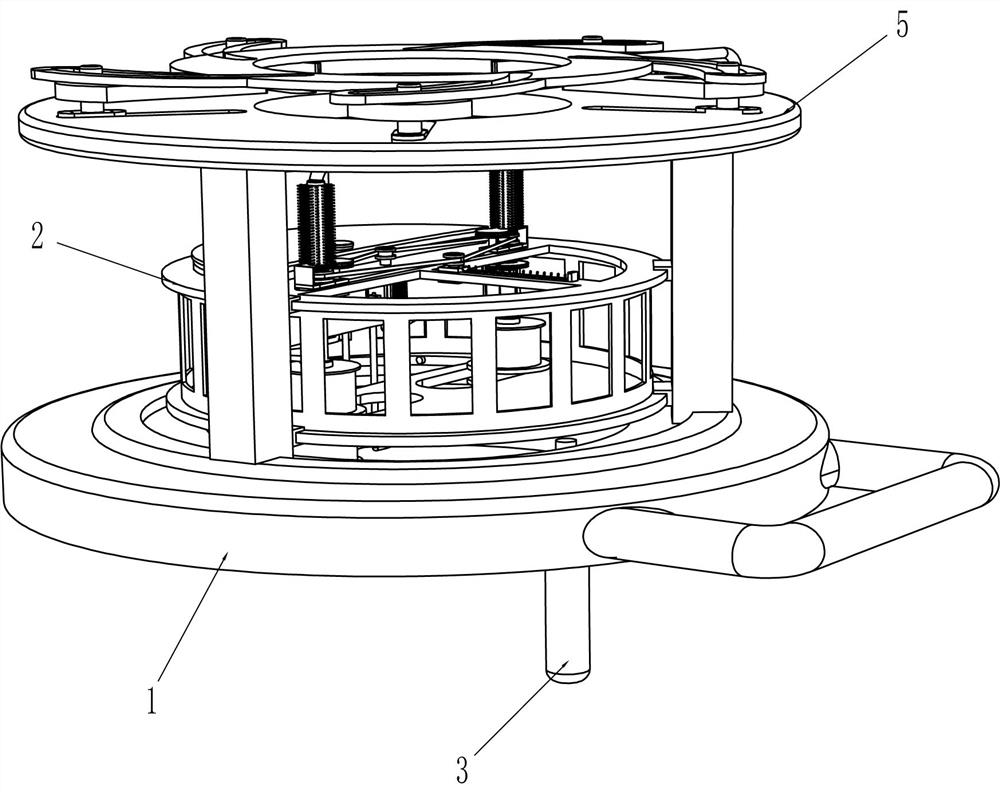

[0028] refer to Figure 1-Figure 6 , a metal pipe spiral part derusting device, including a ring base 1, a rotating frame 2, a rocker 3, a derusting mechanism 4 and a fixing mechanism 5, and the rotating connection between the inner lower parts of the three pillars of the ring base 1 There is a rotating frame 2, the upper part of the rotating frame 2 is provided with a derusting mechanism 4, the top of the ring base 1 is provided with a fixing mechanism 5, and the eccentric position of the outer bottom of the rotating frame 2 is fixedly connected with a rocking handle 3.

[0029]Derusting mechanism 4 comprises horizontal slide block 41, derusting pipe 42, belt pulley 43, guide slider 44, drive motor 45, extension spring 46, guide wheel 47 and drive belt 48, the design of slide type in the middle of rotating frame 2 tops There are two horizontal sliders 41, the top of the horizontal slider 41 is rotatably connected with a derusting pipe 42, and the outside of the lower part of ...

Embodiment 2

[0035] refer to figure 2 , Image 6 , Figure 7 with Figure 8 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a spray mechanism 6 is also included, and the spray mechanism 6 includes a liquid storage tank 61, a cylinder body 62, a one-way liquid inlet pipe 63, and a transmission assembly 64. Piston plate 65, three-way pipe 66, one-way valve 67, external thread liquid outlet pipe 68, movable nozzle pipe 69 and internal thread sleeve 610, cylinder body 62 is slidably connected to the front and rear sides of the bottom of rotating frame 2 , the cylinder body 62 is slidingly provided with a piston plate 65, the eccentric position of the piston plate 65 is connected with a three-way pipe 66, the upper and lower parts of the three-way pipe 66 are provided with a one-way valve 67, and the middle of the top of the cylinder body 62 passes through a sealing ring The sliding type is provided with an internal thread sleeve 610, and the b...

Embodiment 3

[0040] refer to figure 2 with Image 6 Compared with Embodiment 1 and Embodiment 2, the main difference of this embodiment is that in this embodiment, an L-shaped limiting plate 7 is also included, and the outer edge positions of the horizontal sliders 41 on the front and rear sides are fixedly connected with the L-shaped limiting plate. 7. The upper part of the L-shaped limiting plate 7 is located above the transmission gear 643 and the rotating gear 641 , and the derusting pipe 42 runs through the L-shaped limiting plate 7 .

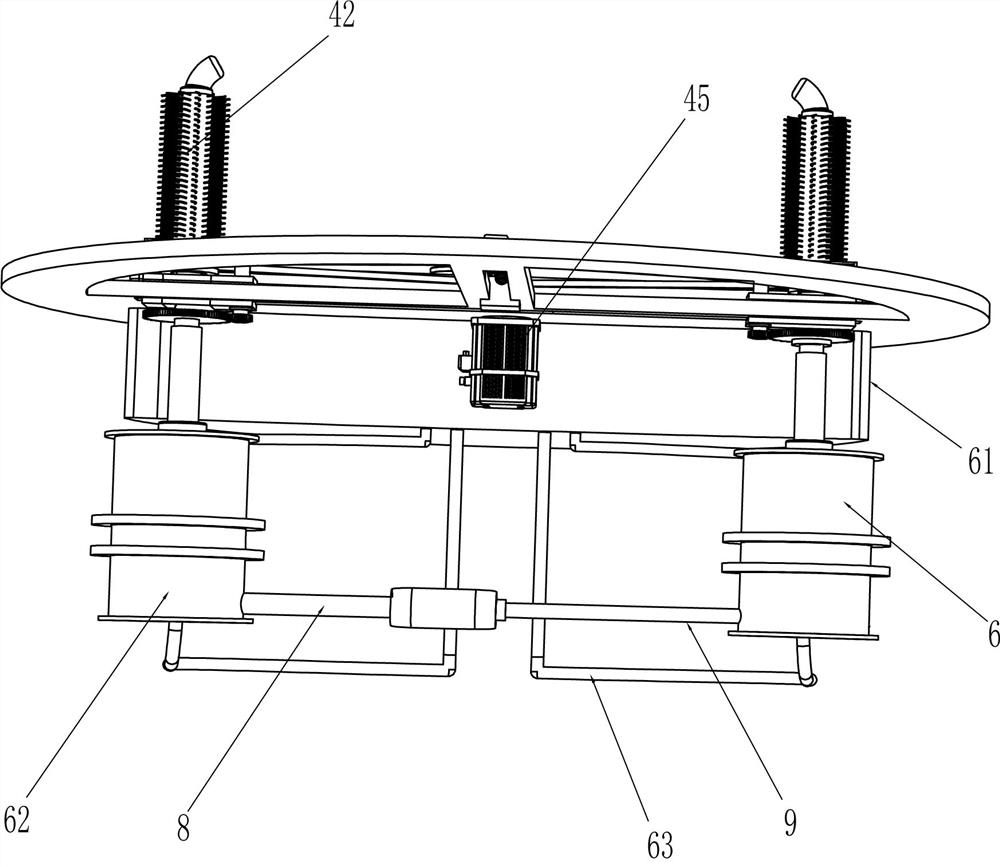

[0041] Also include threaded rod 8 and threaded sleeve 9, the outer and rear lower part of the front side cylinder 62 is rotatably connected with threaded sleeve 9, the internal rotation of threaded sleeve 9 is provided with threaded rod 8, and the rear end of threaded rod 8 It is fixedly connected with the lower part of the outer front side of the rear side cylinder body 62 .

[0042] When the metal pipe is clamped and fixed by the clamping block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com