Omnidirectional vehicle with variable-angle omnidirectional wheels

A technology of omni-directional wheels and corners, applied in the field of omni-directional vehicles, can solve the problems of increased installation compactness and reduced driving efficiency, and achieve the effects of improving driving efficiency, reducing driving dimensions, and reducing control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

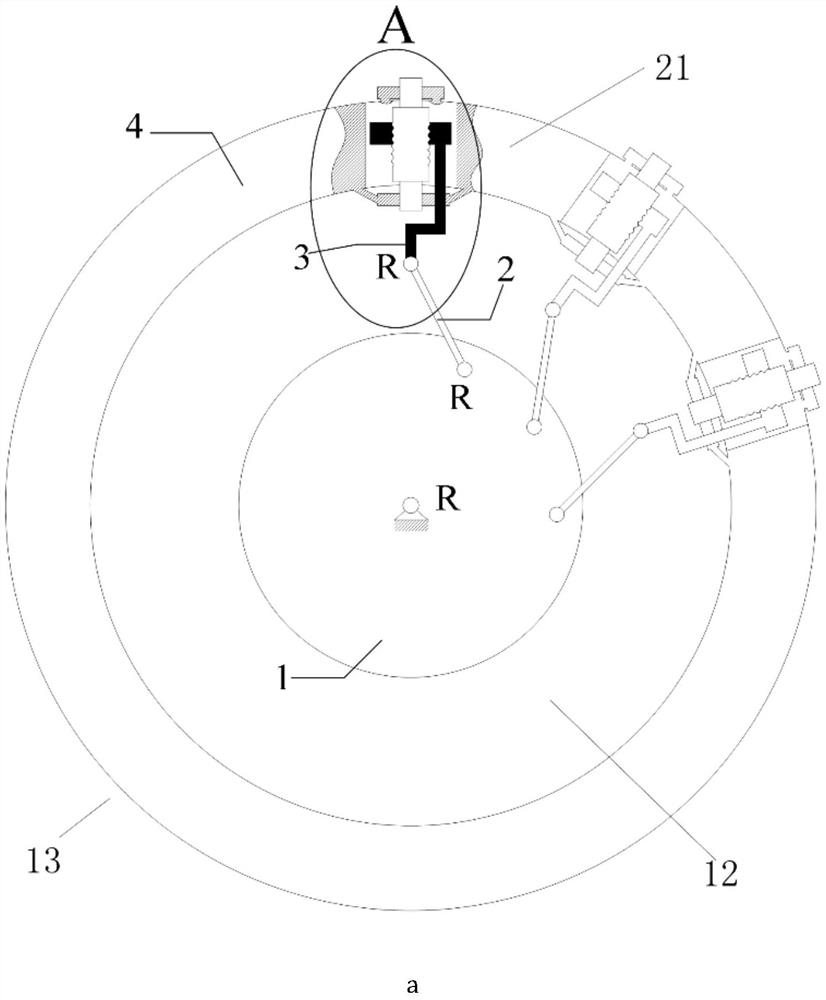

[0034] Such as figure 1 As shown, it is a variable-angle omnidirectional wheel 13 related to this embodiment, which includes: a turntable 23, a rotation angle adjustment device 12, a roller unit 14 and a connecting branch chain device 21, wherein: the rotation angle adjustment device 12 is arranged on the turntable 23 Above, the connecting branch chain device 21 is evenly arranged on the circumference of the rotation angle adjusting device 12 , and the roller unit 14 is connected with the rotation angle adjusting device 12 through the connecting branch chain device 21 .

[0035] The angle adjustment device 12 includes: a rotating active part 1, a connecting rod 2 and a supporting hub 4, wherein: the rotating active part 1 is arranged outside the turntable 23 and inside the supporting hub 4, and one end of the connecting rod 2 is evenly arranged on the rotating active part. On the circumference of part 1, the other end links to each other with connection branch chain device 21....

Embodiment 2

[0041] This embodiment relates to a variable-angle omnidirectional wheel 13, the basic structure of which is consistent with that of Embodiment 1, except that:

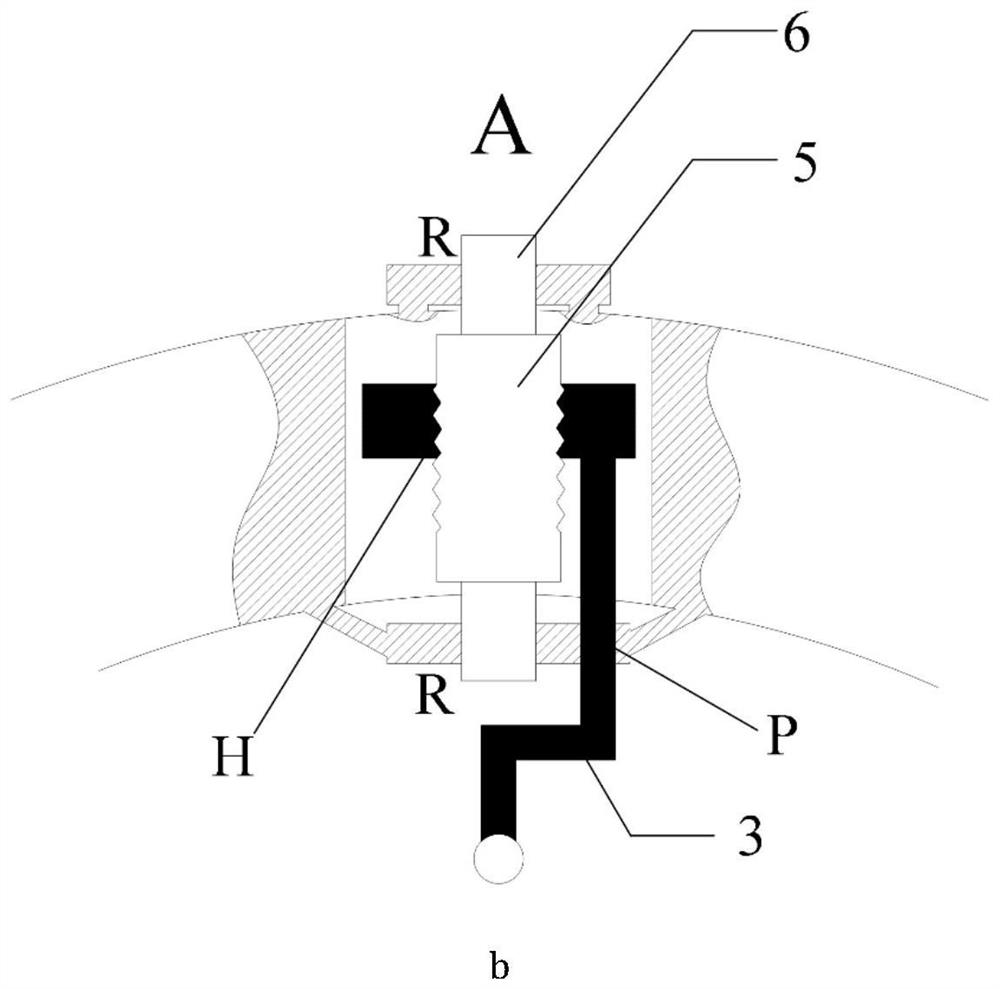

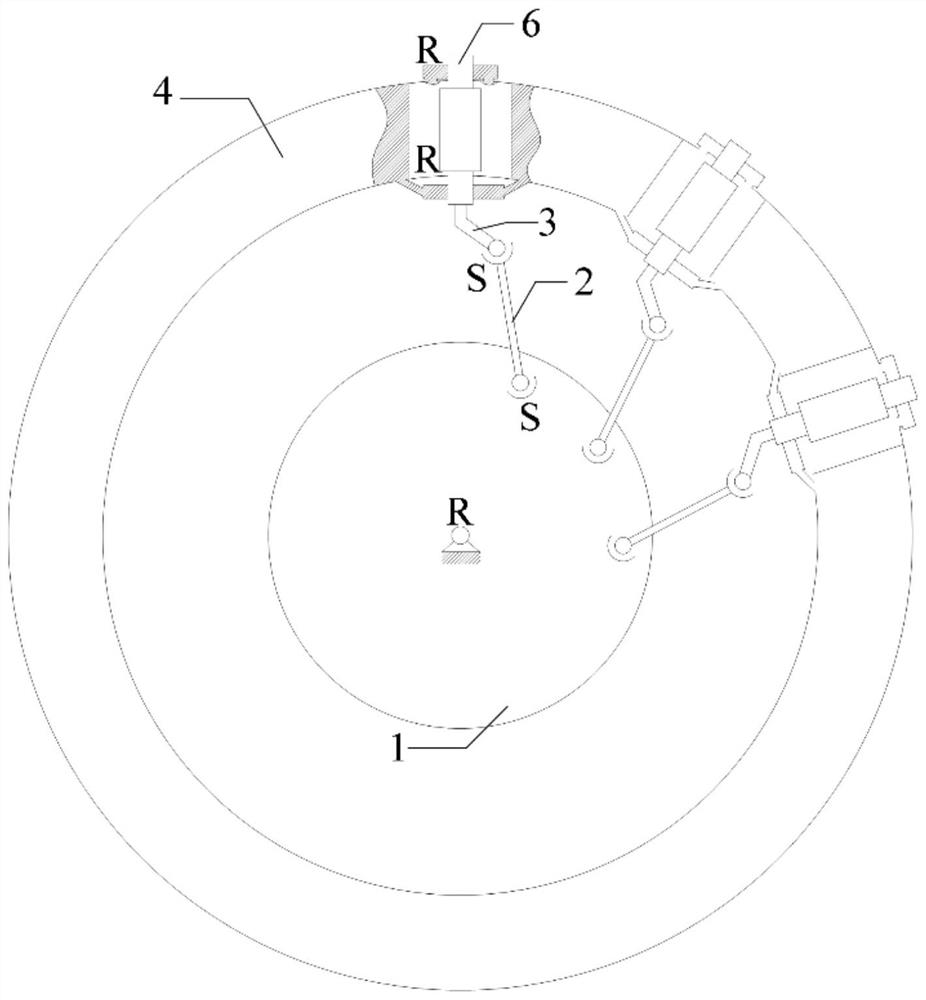

[0042] Such as figure 2 As shown, since the space RSSR and the circular plane are not in the same plane, the rotation of the rotating active part 1 will be transmitted to the end of the branch chain 6 through the space RSSR to make it rotate, and the roller fixedly connected to the end of the branch chain 6 (such as Figure 4 shown) the installation angle is changed.

[0043] Such as Figure 10 shown, for something like figure 2 Take the space RSSR mechanism as an example to realize the adjustment of the installation angle RIA of multiple rollers. The mechanism has n+1 branch chains, and each branch chain shares a turntable (that is, the "moving platform" in the parallel mechanism). Among the n+1 branch chains, one branch chain is the rotating pair R formed by the frame and the turntable. 1 , and the other n br...

Embodiment 3

[0045] This embodiment relates to a variable-angle omnidirectional wheel 13, the basic structure of which is consistent with that of Embodiment 1, except that the vehicle body includes: four second main drive shafts arranged at corners and independent of each other, wherein: the first The two main drive shafts are respectively connected with the variable-angle omnidirectional wheels.

[0046] Such as image 3 As shown, the described rotation angle adjustment device includes: a rotating active part 1, a connecting rod 2, a supporting hub 4, an action wheel 7 and an idler wheel 8, wherein: the rotating active part 1 is arranged in the supporting wheel hub 4, and the operating wheel 7 and the idler wheel The wheels 8 are successively arranged adjacently on the circumference of the rotating active part 1 , one end of the connecting rod 2 is connected with the action wheel, and the other end is connected with the connecting branch chain device 21 .

[0047] The rotating active par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com