Automatic conveying device for automobile parts and conveying method

An auto parts, automatic technology, applied in the conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problem that the conveying device cannot be moved, and the height and angle of the conveying table cannot be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

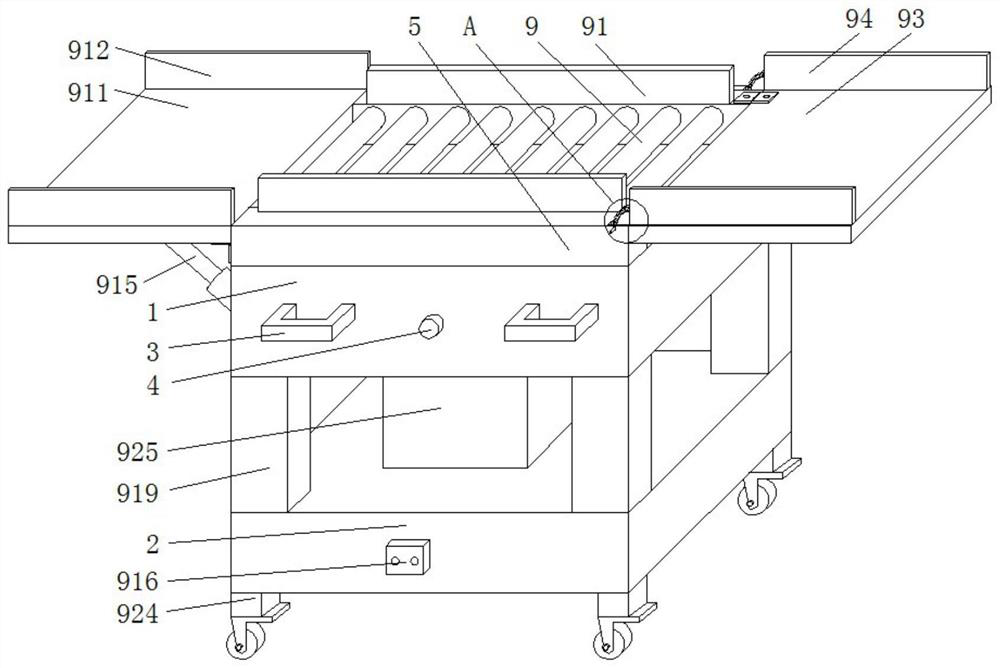

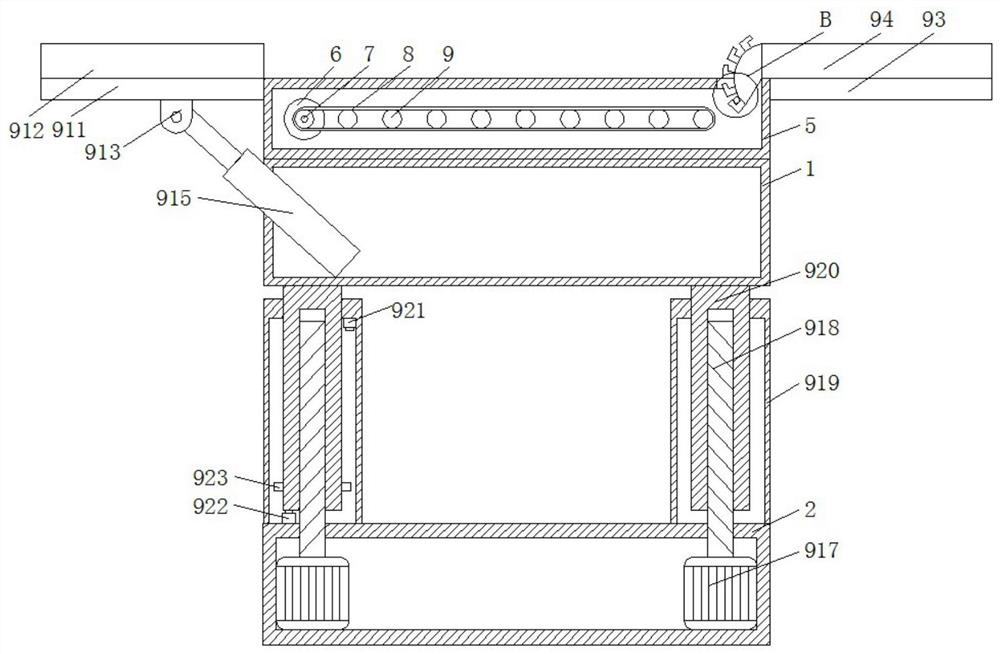

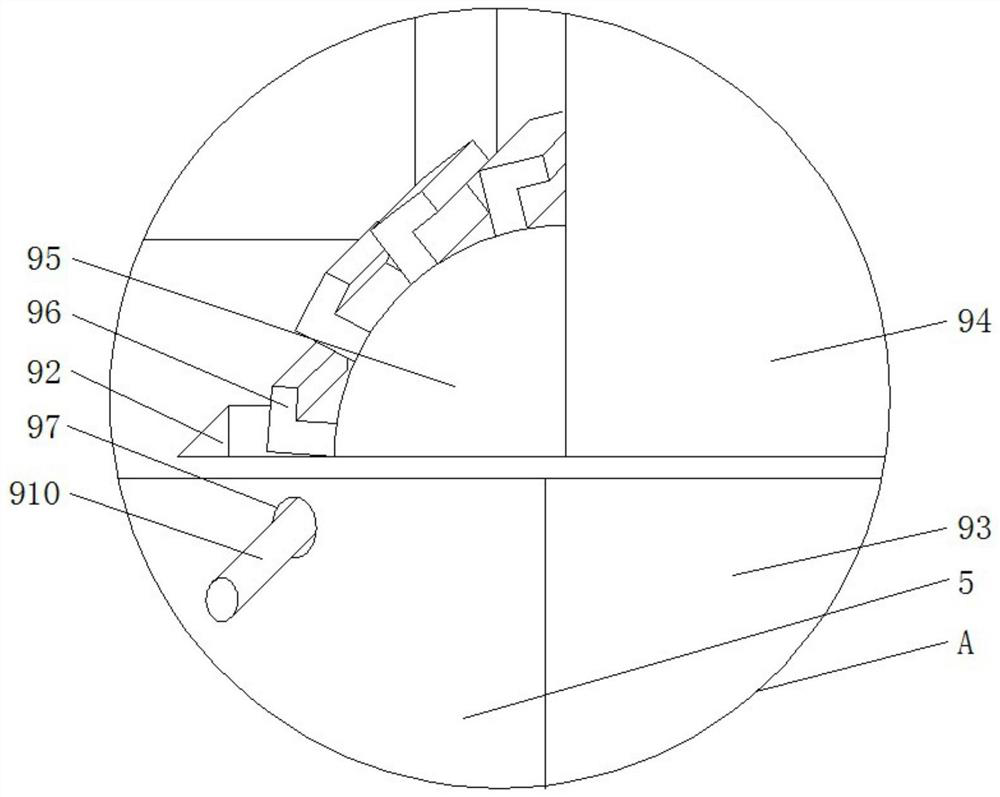

[0029] refer to Figure 1-6 , an automatic feeding device for auto parts, comprising a workbench 1 and a base 2, the front and back of the workbench 1 are fixedly connected with symmetrically distributed handles 3, the front of the workbench 1 is fixedly equipped with a start switch 4, the working The upper surface of the table 1 is fixedly connected with a mounting block 5, the rear inner walls of the two mounting blocks 5 are fixedly mounted with a first motor 6, and the output shafts of the two first motors 6 are fixedly mounted with a first transmission shaft through a coupling 7. The outer surfaces of the two first transmission shafts 7 are fixedly sleeved with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com