A kind of bio-based macromolecule flame retardant and its preparation method and application

A bio-based macromolecule and flame retardant technology, applied in the field of flame retardants, can solve problems such as poor thermal stability of tannins, and achieve the effect of solving poor thermal stability, good thermal stability and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

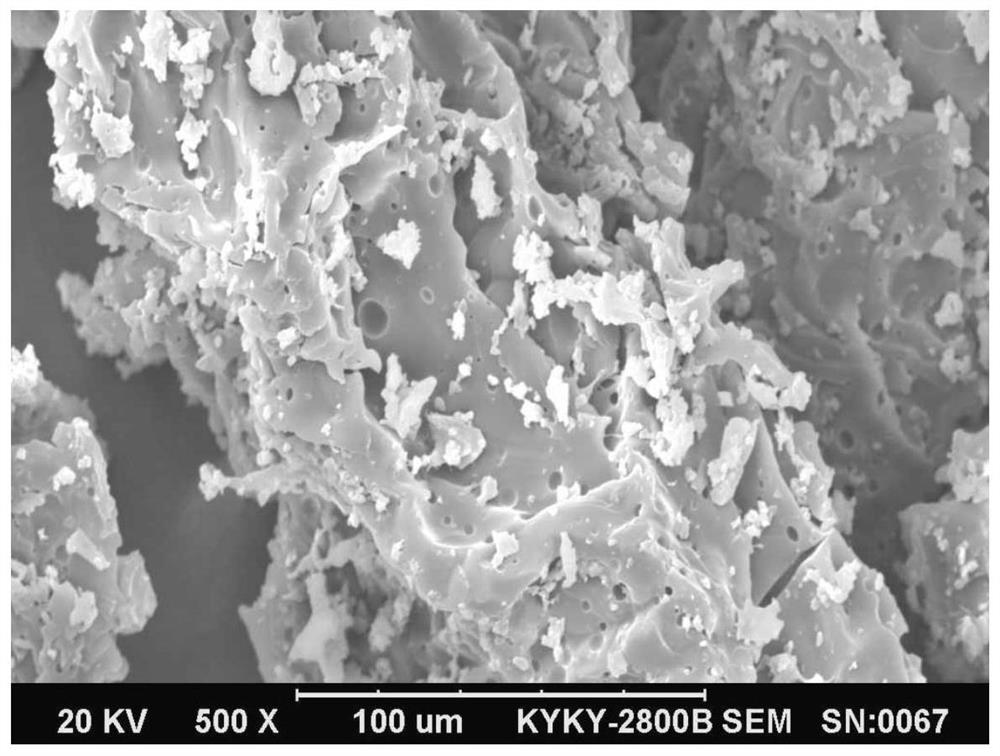

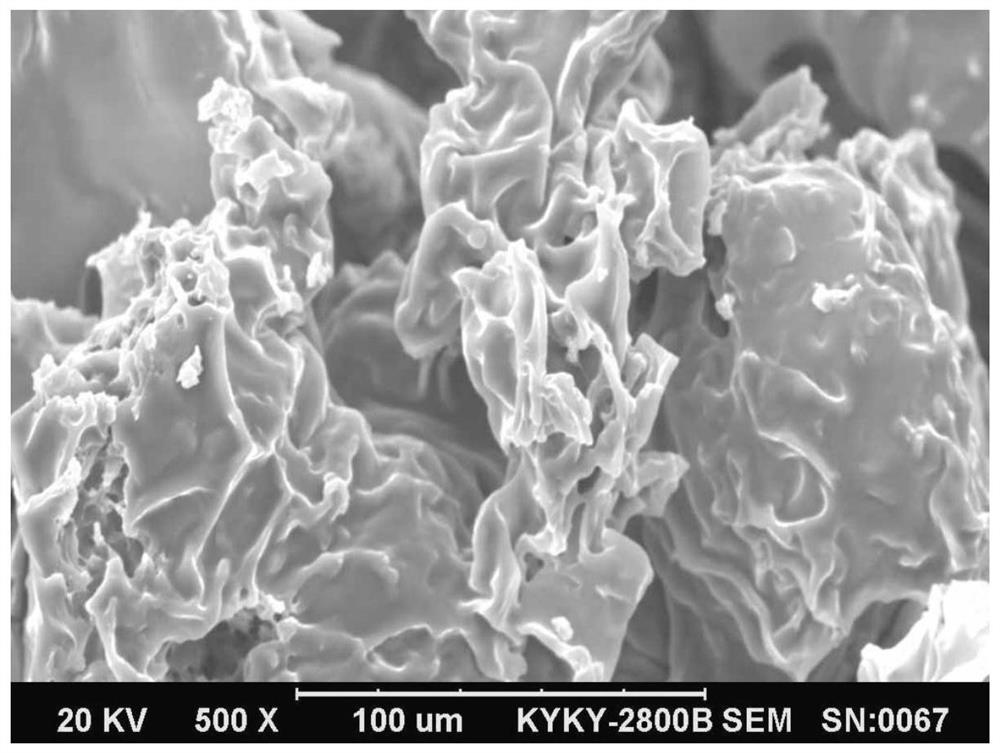

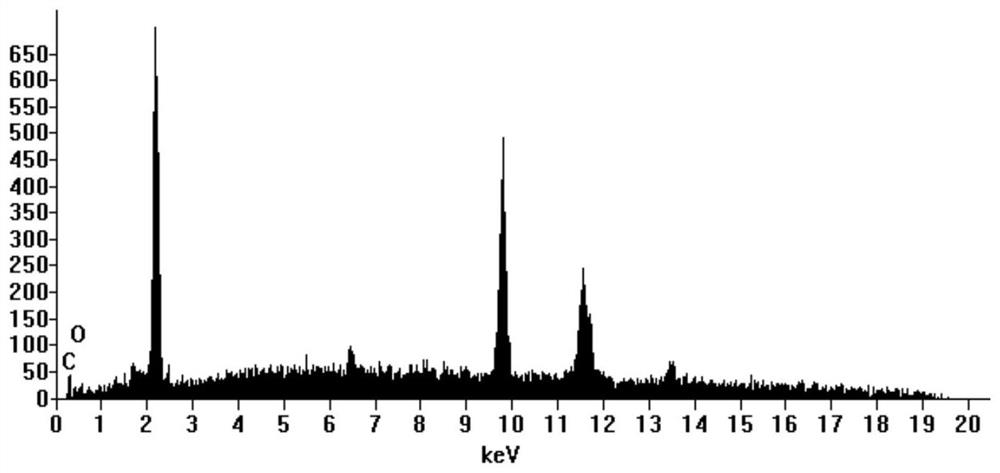

Image

Examples

Embodiment 1

[0029] A preparation method of a bio-based macromolecular flame retardant, comprising the following steps:

[0030] (1) Preparation of tannin chlorinated phosphazene by grafting method: add 20g of tannic acid and 10mL of triethylamine to 100ml of acetonitrile to obtain a mixture, heat the mixture to 40°C, and add hexachlorotripolyphosphorus dropwise Add 20ml of nitrile to the mixture, then heat the mixture at 50°C for 2h to obtain a mixed solution containing tannin chlorinated phosphazene ester;

[0031] (2) Reaction of tannin chlorinated phosphazene ester with m-phenylenediamine: add 20 g of m-phenylenediamine to the mixed solution in step (1), heat to 70°C for 3 hours, filter and wash with acetonitrile to remove three Ethylamine salt and unreacted raw materials are dried to obtain a bio-based macromolecular flame retardant (TAFR), and the conversion rate of TAFR is 80-90%.

[0032] The bio-based macromolecule flame retardant is used for the preparation of flame-retardant ep...

Embodiment 2

[0064] A preparation method of a bio-based macromolecular flame retardant, comprising the following steps:

[0065] (1) Preparation of tannin chlorinated phosphazene by grafting method: 10 g of tannic acid and 5 mL of triethylamine were added to 50 mL of acetonitrile to obtain a mixture, the mixture was heated to 30 ° C, and hexachlorotripolyphosphorus was added dropwise Nitrile 10ml was added to the mixture, and then the mixture was heated at 50° C. for 1 h to obtain a mixed solution containing tannin chlorinated phosphazene ester;

[0066] (2) Reaction of tannin phosphazene chloride with m-phenylenediamine: add 10 g of m-phenylenediamine to the mixed solution in step (1), heat to 60°C for 2 hours, filter and wash with acetonitrile to remove three Ethylamine salt and unreacted raw materials are dried to obtain a bio-based macromolecular flame retardant (TAFR).

[0067] The bio-based macromolecule flame retardant is used for the preparation of flame-retardant epoxy resin, and...

Embodiment 3

[0072] A preparation method of a bio-based macromolecular flame retardant, comprising the following steps:

[0073] (1) Preparation of tannin chlorinated phosphazene by grafting method: 30g of tannic acid and 20mL of triethylamine were added to 200ml of acetonitrile to obtain a mixture, the mixture was heated to 45°C, and hexachlorotripolyphosphorus was added dropwise Add 40ml of nitrile to the mixture, and then heat the mixture at 50°C for 3h to obtain a mixed solution containing tannin chlorinated phosphazene ester;

[0074] (2) Reaction of chlorinated phosphonitrile tannin with m-phenylenediamine: add 30 g of m-phenylenediamine to the mixed solution in step (1), heat to 80°C for 4 hours, filter and wash with acetonitrile to remove three Ethylamine salt and unreacted raw materials are dried to obtain a bio-based macromolecular flame retardant (TAFR).

[0075] The bio-based macromolecule flame retardant is used for the preparation of flame-retardant epoxy resin, and the flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com