Safe and environment-friendly coke oven shutdown method

A safety and environmental protection, coke oven technology, applied in the furnace safety device, coke oven, petroleum industry and other directions, can solve the problems of production impact, production interruption, resource waste, etc. in iron and steel complexes, saving resources, preventing fire and explosion, The effect of avoiding security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

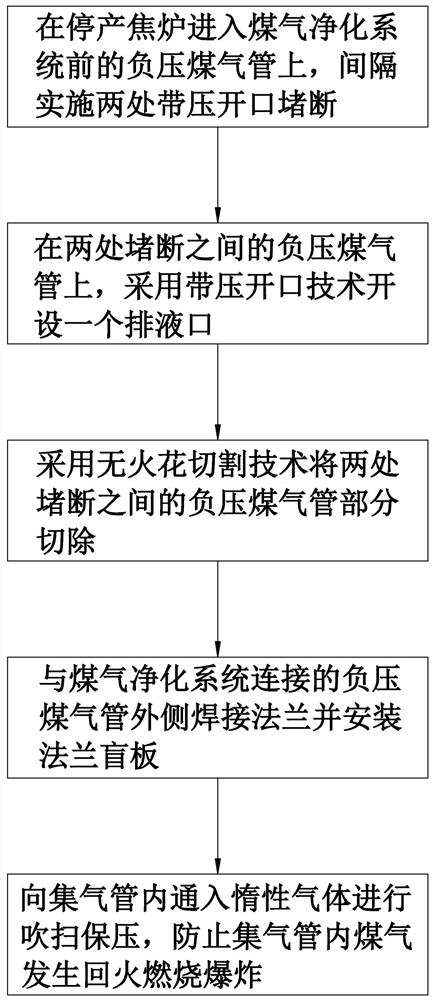

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

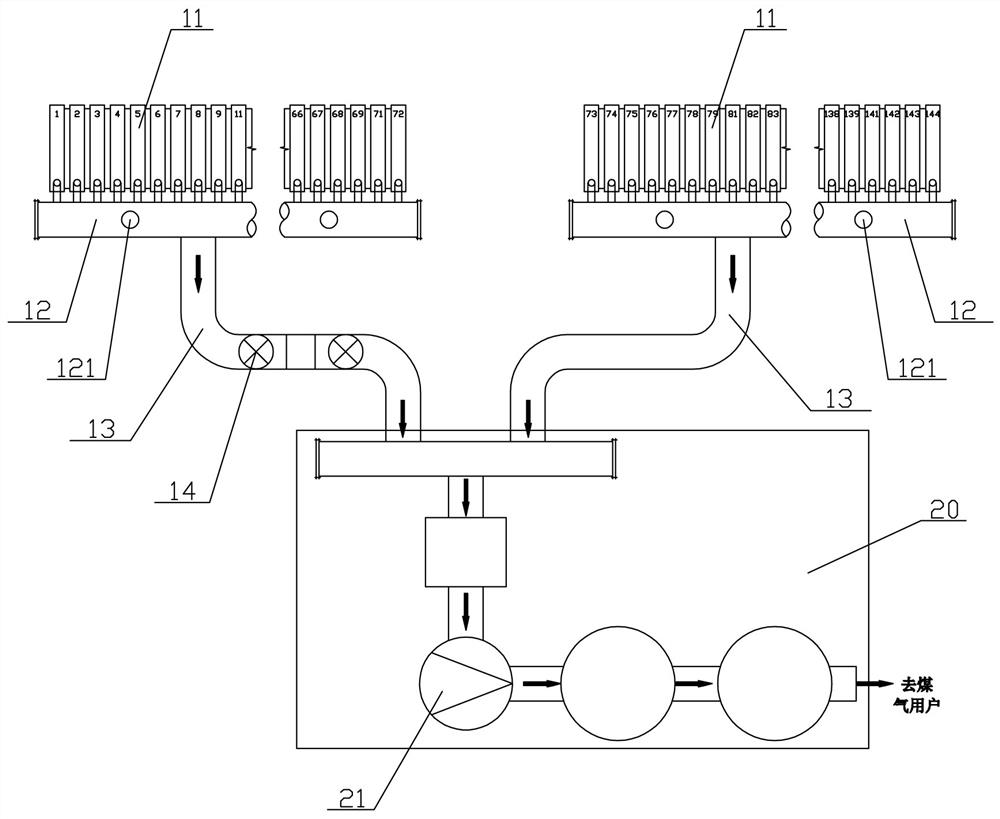

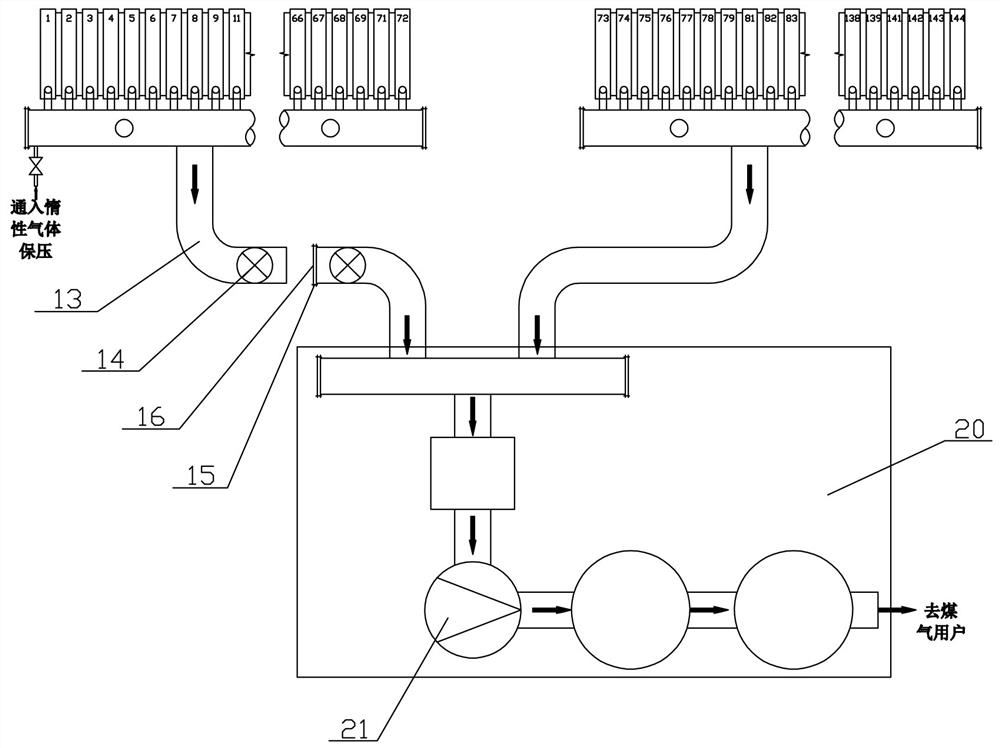

[0027] Coke oven production system, see figure 1 or figure 2 , with two coke ovens as a group, the two coke ovens share a set of gas blower 21 and gas purification system 20 . Each coke oven comprises several carbonization chambers 11, and the coal gas produced by the several carbonization chambers 11 of each coke oven is connected to a gas pipe 13 through a gas collecting pipe 12, and the two gas pipes 13 are respectively connected to a gas purification system 20 to The gas is purified, and the purified gas then flows to each gas user. A number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com