Gas circulation jet cooling device

A cooling device and gas circulation technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of narrow adjustment range of cooling capacity, complex structure, poor cooling uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

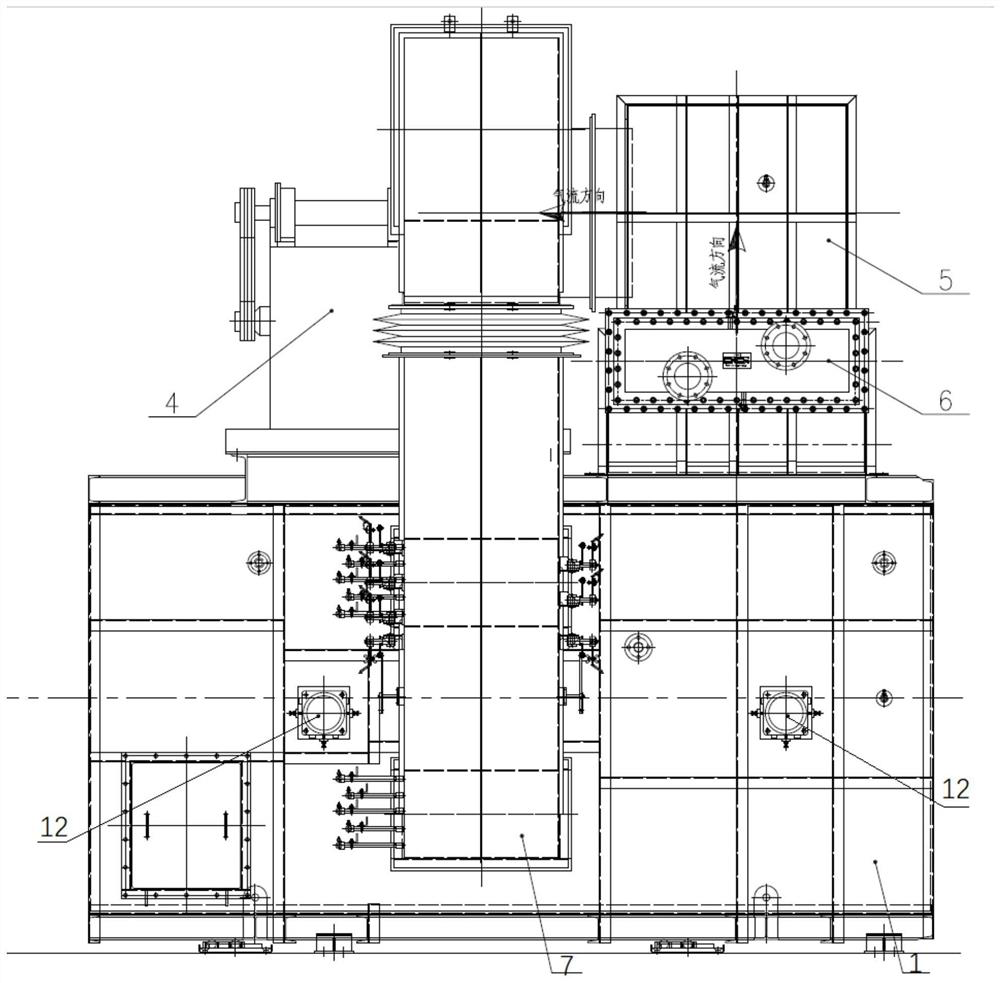

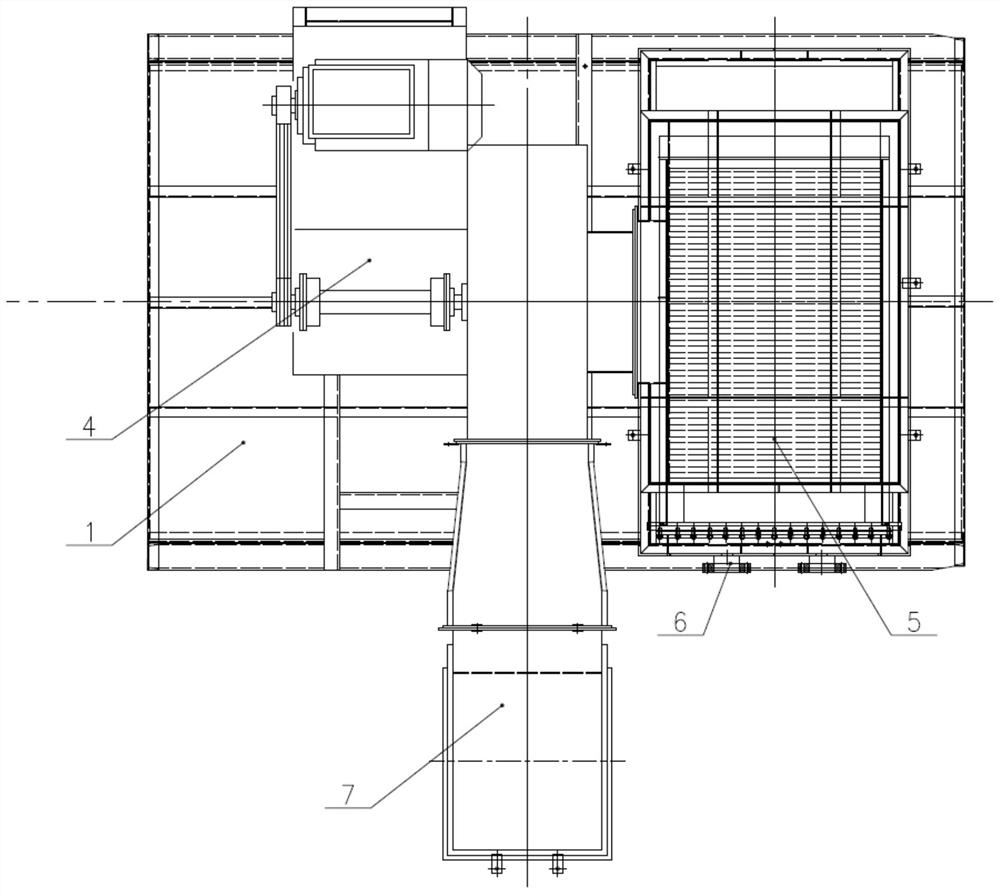

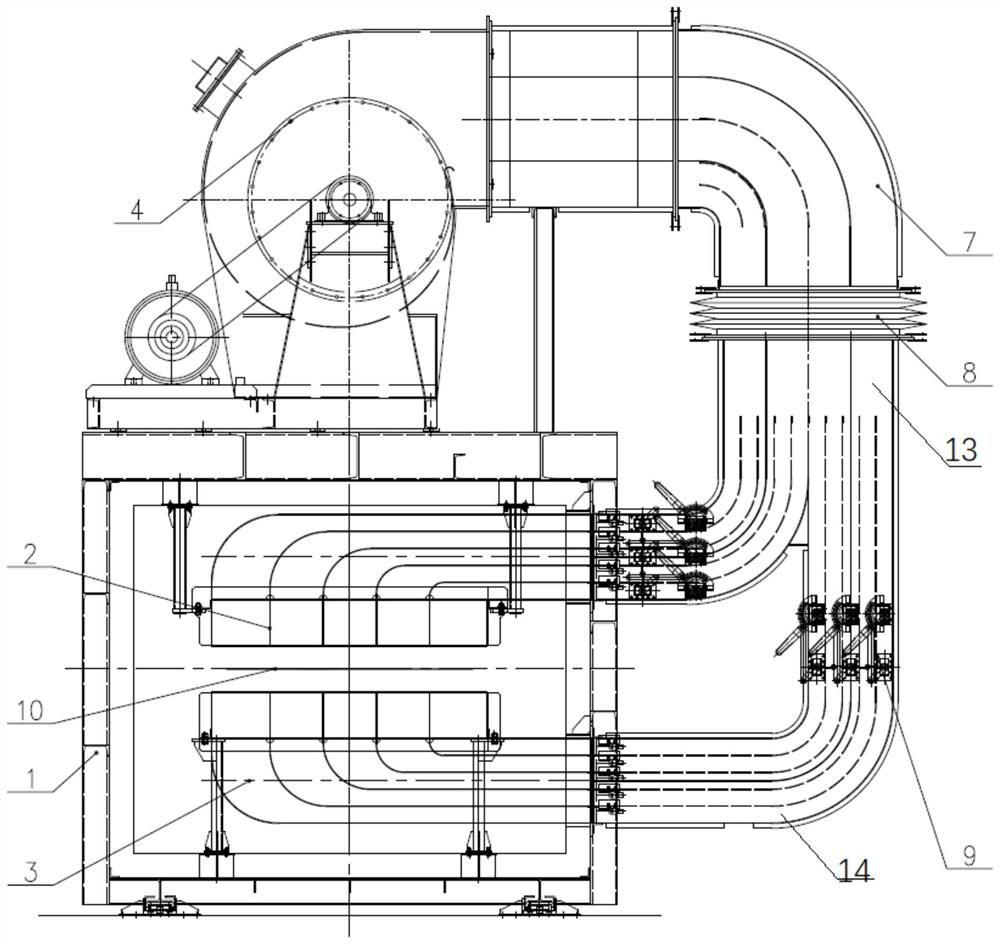

[0026] Such as Figure 1 to Figure 7 Shown, a kind of gas circulation injection cooling device comprises the cooling box 1 that strip steel 10 can pass through closed, circulation blower 4 and air channel 7, and the upper and lower sides of strip steel 10 passing position in cooling box 1 are respectively provided with upper spray box 2 and The lower spray box 3, the upper spray box 2 and the lower spray box 3 are all distributed with air injection holes 11 facing the side of the strip 10, and the top of the cooling box 1 is connected to be provided with a gas collection box 5, and the entrance of the gas collection box 5 is provided with The outlet of the heat exchanger 6 is connected to the inlet of the circulating fan 4, the outlet of the circulating fan 4 is connected to the inlet of the air duct 7, and the outlet of the air duct 7 is divided into t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap