Structure and method for improving connecting performance of CFT pillow type ballastless track and lower foundation

A technology of ballastless track and connection performance, applied in the direction of track, road, ballast layer, etc., can solve the problems of high cost, large working space, and difficult control, and achieve simple construction, increased contact area, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

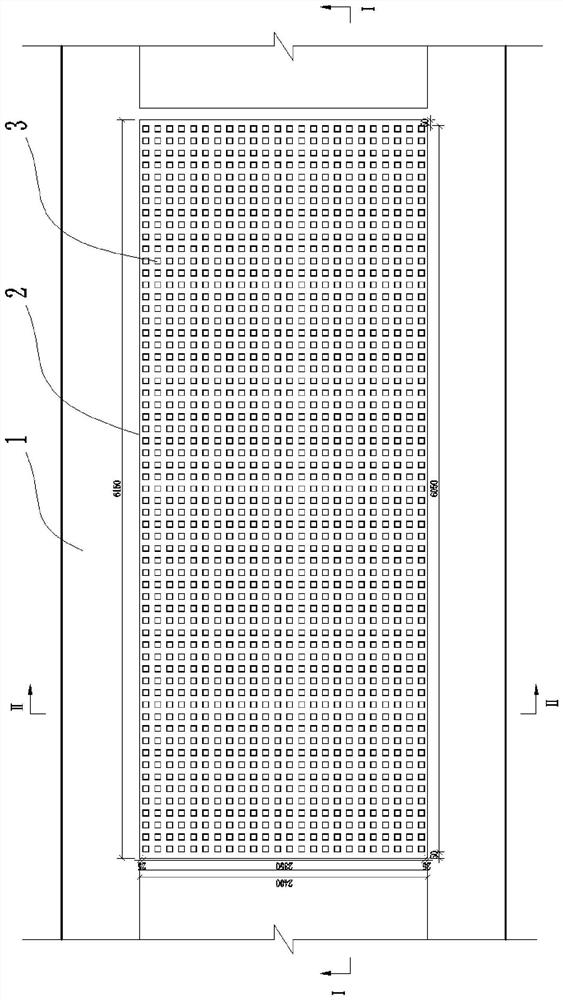

[0035] Such as Figure 1-3 As shown, the present invention provides a structure for improving the connection performance between the CFT pillow ballastless track and the lower foundation. In the lower foundation 1, the area 2 (the size is 6150× 2400mm), a number of bosses 3 protruding upward from the reference surface of the lower foundation 1 are evenly arranged in a matrix, and grooves 4 are formed between adjacent bosses 3, and grooves 4 of the grooves 4 The bottom surface is flush with the reference plane of the lower foundation 1 ; the poured concrete of the ballast bed slab covers and fills the boss 3 and the groove 4 , and is connected with the lower foundation 1 .

[0036] The size of the boss matrix is 6050×2350mm, the vertical distance from the sideline of the area 2 is 50mm, and the horizontal distance is 25mm.

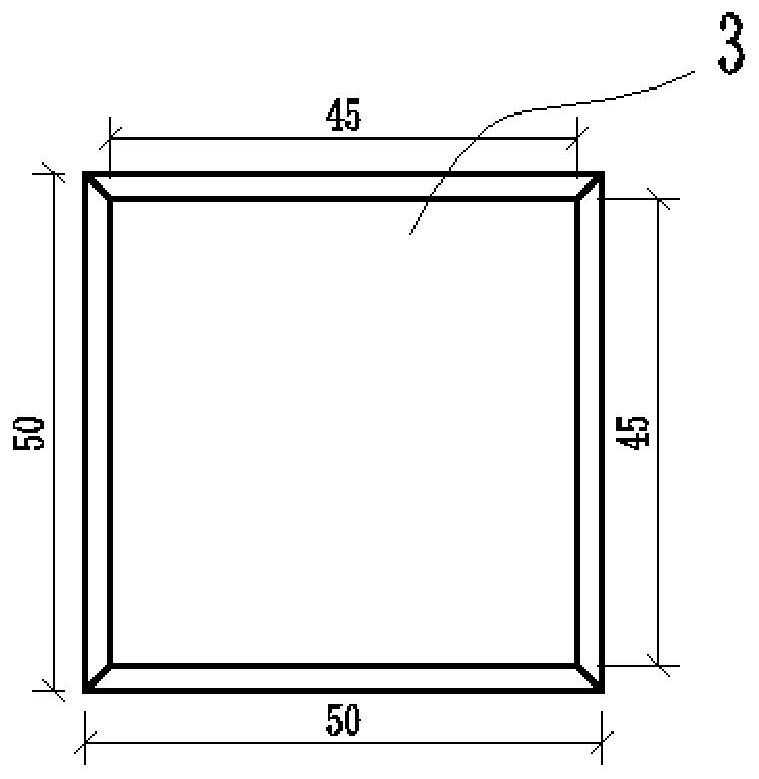

[0037] Preferably, the boss 3 is a prism, and the area of the upper surface of the prism is smaller than the area of the lower surface. Preferably,...

Embodiment 2

[0044] Such as figure 1 , 3 , 4, the present invention provides a structure that improves the connection performance between the CFT pillow ballastless track and the lower foundation. 6150×2400mm), a number of bosses 3 protruding upward from the reference surface of the lower foundation 1 are uniformly arranged in a matrix, and grooves 4 are formed between adjacent bosses 3, and the grooves The bottom surface of 4 is flush with the reference plane of the lower foundation 1; the pouring concrete of the ballast bed slab covers and fills the boss 3 and the groove 4, and is connected with the lower foundation 1.

[0045] Preferably, the lower foundation 1 is a bridge beam surface.

[0046] The size of the boss matrix is 6050×2350mm, the vertical distance from the sideline of the area 2 is 50mm, and the horizontal distance is 25mm.

[0047] Preferably, the boss 3 is a prism, and the area of the upper surface of the prism is smaller than the area of the lower surface. Pref...

Embodiment 3

[0054] Such as figure 1 , 3 , 5, the present invention provides a structure for improving the connection performance between the CFT pillow ballastless track and the lower foundation, in the lower foundation 1, the area 2 (the size of which is 6150×2400mm), a number of bosses 3 protruding upward from the reference surface of the lower foundation 1 are uniformly arranged in a matrix, and grooves 4 are formed between adjacent bosses 3, and the grooves The bottom surface of 4 is flush with the reference plane of the lower foundation 1; the pouring concrete of the ballast bed slab covers and fills the boss 3 and the groove 4, and is connected with the lower foundation 1.

[0055] Preferably, the lower foundation 1 is a tunnel invert.

[0056] The size of the boss matrix is 6050×2350mm, the vertical distance from the sideline of the area 2 is 50mm, and the horizontal distance is 25mm.

[0057] Preferably, the boss 3 is a prism, and the area of the upper surface of the prism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com