Pavement maintenance vehicle

A technology for car maintenance and car body, applied in roads, roads, road repair and other directions, can solve problems such as low cleaning efficiency, nozzle blockage, road damage, etc., to reduce workload and prevent nozzle blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

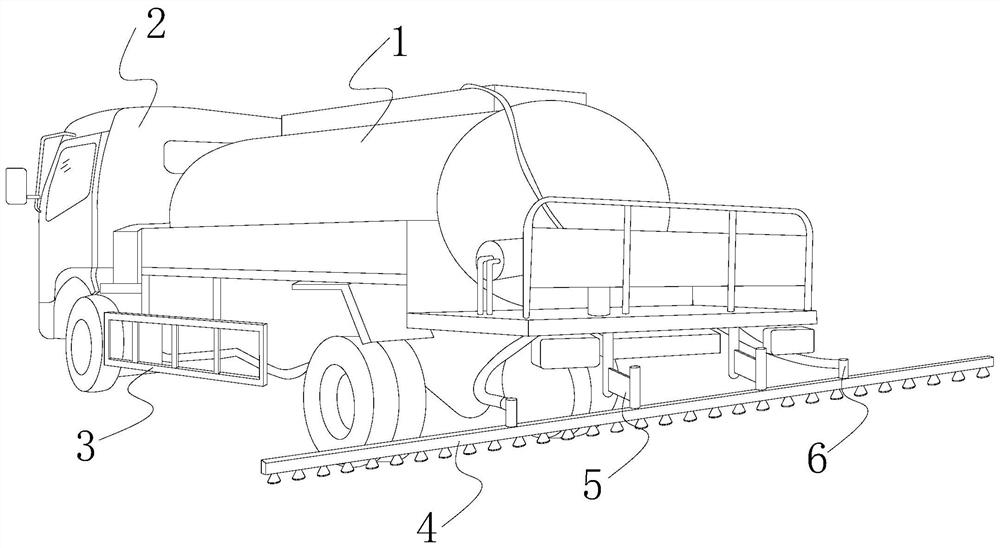

[0030] see Figure 1-6 , the present invention provides a technical solution of a road maintenance vehicle: its structure includes an asphalt spreader 1, a vehicle body 2, a side bracket 3, a spraying pipe 4, a connecting frame 5, and a delivery pipe 6. The two parts of the vehicle body 2 Side brackets 3 are provided on both sides, and an asphalt spreader 1 is arranged on the car body 2. The asphalt spreader 1 is connected to the spray pipe 4 through the delivery pipe 6, and the spray pipe 4 is connected to the spray pipe 4 through the connecting frame 5. Body 2.

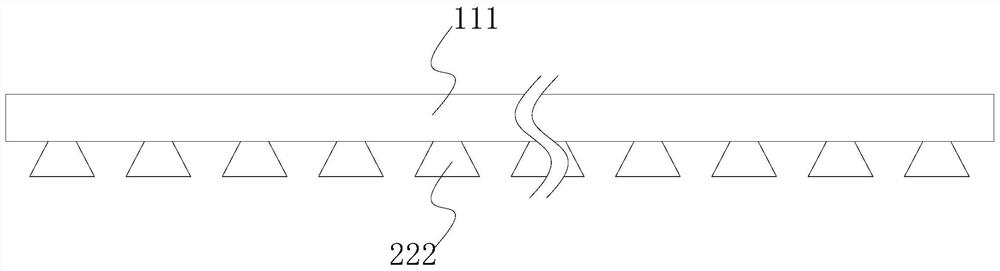

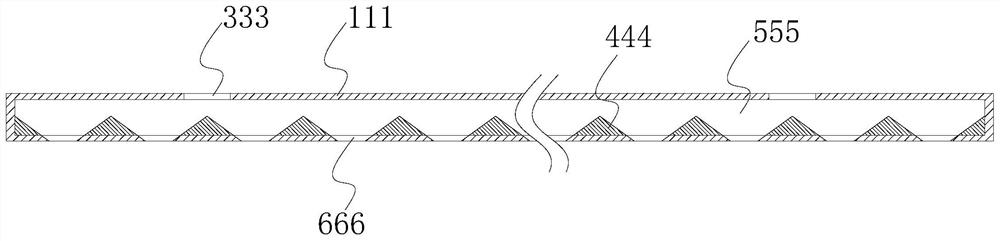

[0031] The spray pipe 4 includes a pipe body 111, a nozzle 222, a liquid inlet 333, an isosceles triangular prism 444, a liquid cavity 555, and a liquid outlet 666. The two ends of the pipe body 111 are closed ends, and the pipe body 111 is closed. The top of 111 is provided with a liquid inlet 333, and the liquid inlet 333 communicates with the liquid chamber 555. The inside of the tube body 111 is evenly distribu...

Embodiment 2

[0036] see Figure 1-9 , the present invention provides a technical solution of a road maintenance vehicle: its structure includes an asphalt spreader 1, a vehicle body 2, a side bracket 3, a spraying pipe 4, a connecting frame 5, and a delivery pipe 6. The two parts of the vehicle body 2 Side brackets 3 are provided on both sides, and an asphalt spreader 1 is arranged on the car body 2. The asphalt spreader 1 is connected to the spray pipe 4 through the delivery pipe 6, and the spray pipe 4 is connected to the spray pipe 4 through the connecting frame 5. Body 2.

[0037] The spray pipe 4 includes a pipe body 111, a nozzle 222, a liquid inlet 333, an isosceles triangular prism 444, a liquid cavity 555, and a liquid outlet 666. The two ends of the pipe body 111 are closed ends, and the pipe body 111 is closed. The top of 111 is provided with a liquid inlet 333, and the liquid inlet 333 communicates with the liquid chamber 555. The inside of the tube body 111 is evenly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com