Tension-compression assembly type beam string structure steel supporting system

A support system and prefabricated technology, used in excavation, construction, infrastructure engineering, etc., can solve problems such as difficulty in dealing with the uncertainty of foundation pit excavation, the separation of the enclosure structure from the support, and the inconsistency of calculation force assumptions. To achieve the effect of convenient construction, convenient construction and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

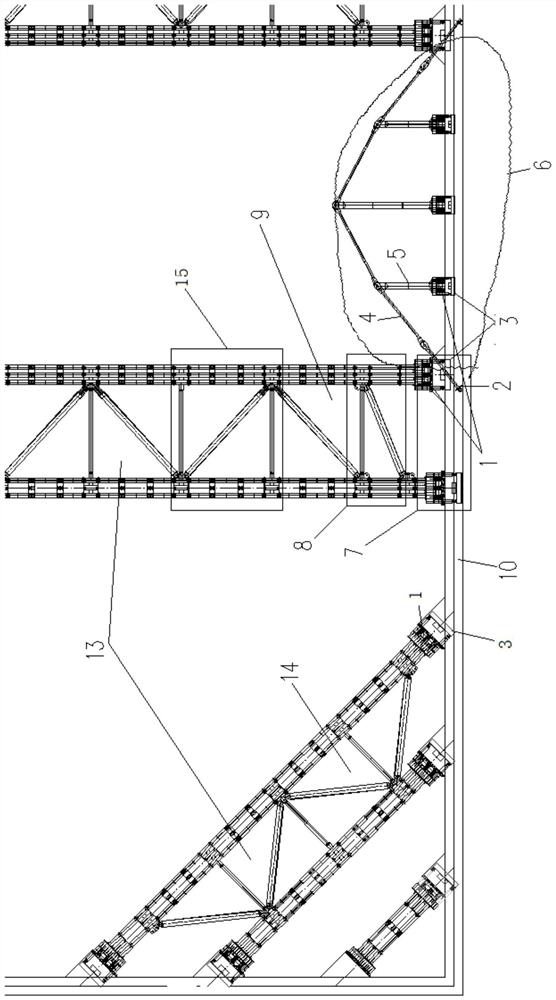

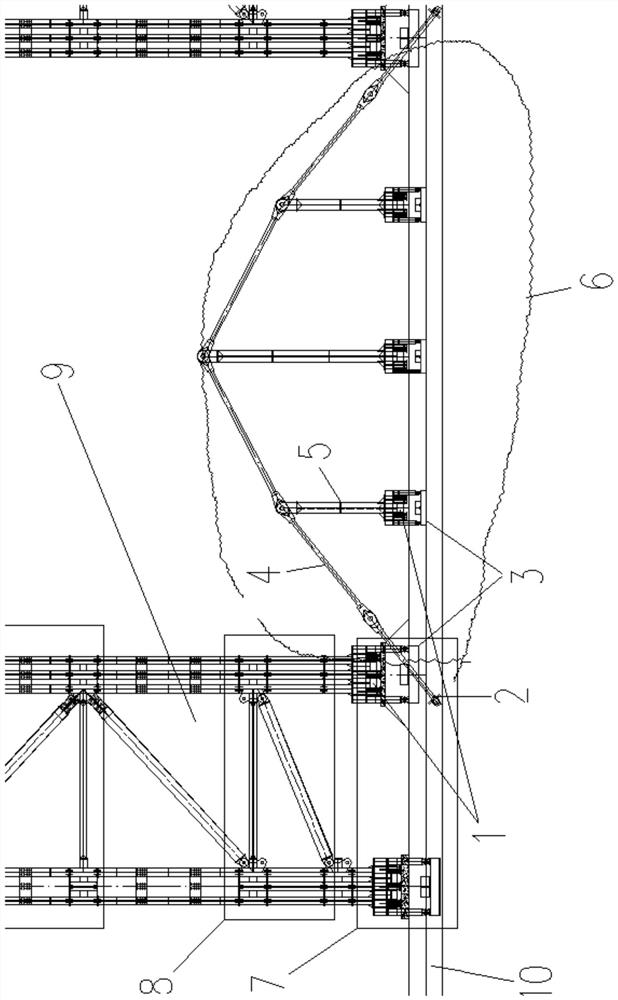

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

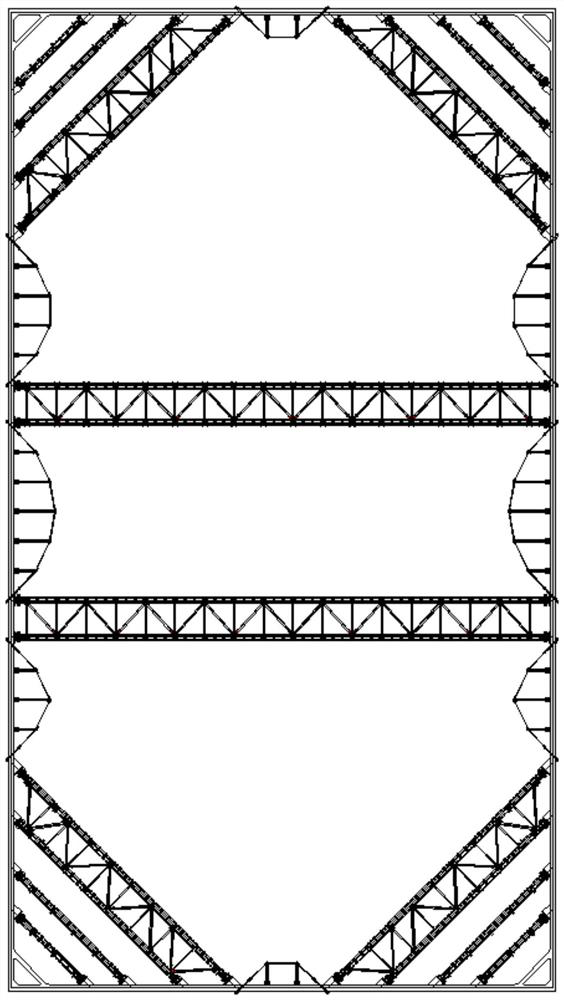

[0034] see Figure 1-Figure 3 , tension-compression steel support system, including concrete beam 10, tensile truss support system 13, combined tension beam system 6; the concrete beam 10 is located on the inner wall of the foundation pit; Tie rod 2, tensile connection device 3, prestressing device, the end tie rod 2 is embedded in the concrete, the middle tie rod 4, end tie rod 2, and strut 5 are hinged, and the end of the strut contains a prestressing device , and connected to the concrete beam 10 through the tensile connection device 3 . Tensile truss support system 13 is divided into tensile truss corner braces and tensile truss straight braces, all of which are connected by multiple units, including standard truss units belonging to standard modules and adjustable truss units belonging to non-standard modules to adapt to different The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com