A shale reservoir controlled fracture uniform expansion fracturing method

A shale reservoir and fracturing technology, which is applied in the field of unconventional oil and gas reservoir development, can solve problems such as the promotion and application of limited volume fracturing technology and large stress differences, and achieve the promotion of cost reduction and efficiency increase development, strong adaptability, large The effect of practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] As the most basic embodiment of the present invention, this example discloses a shale reservoir fracture-controlled uniform expansion fracturing technology, which specifically includes the following steps:

[0052] A shale reservoir controlled fracture uniform expansion fracturing technology specifically includes three key methods and technical components: fracturing scheme design, well-entry material selection, and on-site construction implementation. The specific steps are as follows:

[0053] Step 1: Fracturing scheme design, which mainly includes segmental design, perforation design, scale design and temporary plugging design.

[0054] S1: Segmented design, that is, it is required that the proposed rupture pressure difference within the segmented length is less than the temporary plugging capacity, that is:

[0055] f(△σ,△p p )d (1)

[0056] where f(△σ,△p p ) is the pseudo-rupture pressure difference of the length of the segment, △σ is the stress difference with...

example 1

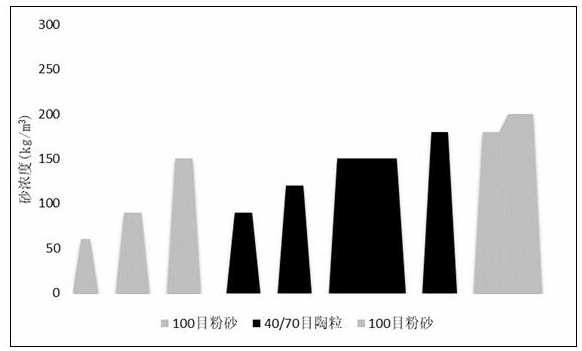

[0077] The optimal proppant combination determined in Example 1 is 40 / 70 mesh ceramsite with a strength greater than 50MPa and 100 mesh quartz sand with a strength greater than 30MPa, and the combination ratio range of the two is 0.3-0.7.

[0078] S6: Optimal fracturing fluid, the viscosity that meets the requirements of fracture creation and sand carrying is:

[0079] mu 1 >max{μ f ,μ p} (11)

[0080] where μ f ,μ p Respectively are the fluid viscosities that meet the requirements of fracture-making and sand-carrying, and the viscosity required to meet the production conditions is:

[0081] mu 2 s ,r l ) (12)

[0082] where r s ,r l are the median pore throat and fluid molecular radius of the shale reservoir, f(r s ,r l ) is the viscosity of the fluid before breaking. According to this, there is a preferred range of fracturing fluid viscosity:

[0083] μ∈[μ 1 ,μ2 ] (13)

[0084] The optimal fracturing fluid viscosity range determined in Example 1 is 1.6-5.4 mP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com