Device and method for automatically cleaning and cooling constant-temperature machine condenser

An automatic cleaning and condenser technology, which is applied in the direction of cleaning heat transfer devices, flushing, and heat exchanger types, etc., can solve the problems of blocking the space of condensation fins, affecting the heat dissipation effect, and easy accumulation of dust in condensation fins, so as to ensure stability, The effect of large spraying range and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

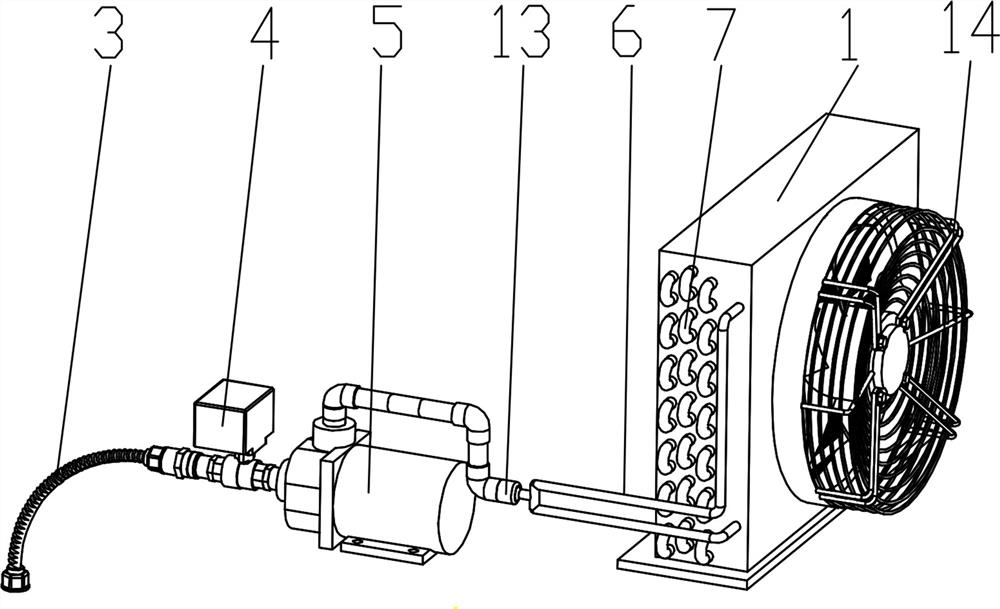

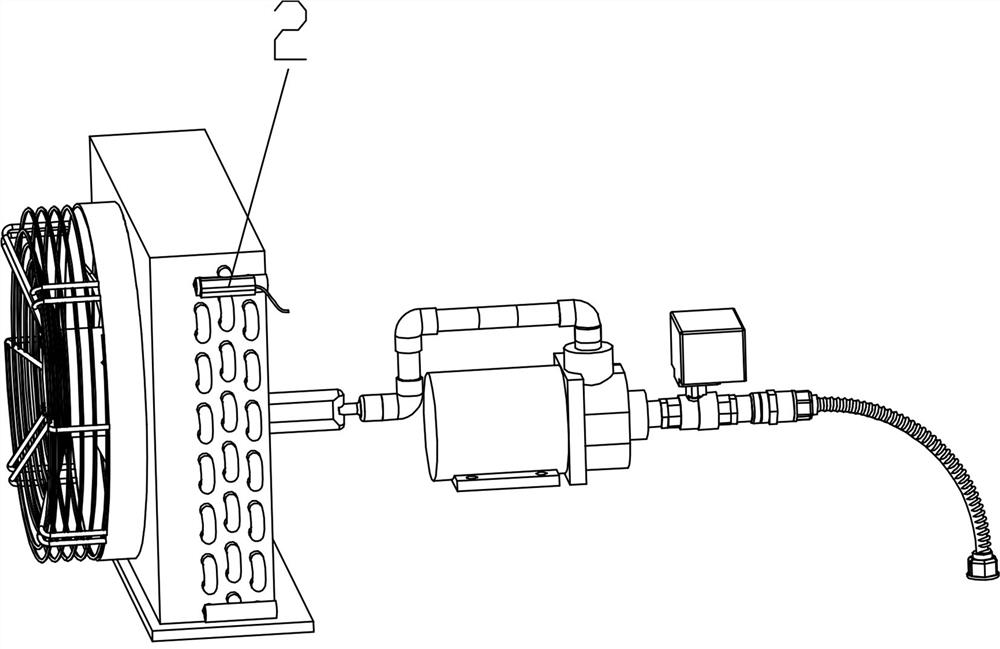

[0031] Embodiment 1: a device for automatic cleaning and cooling of a thermostat condenser, which is provided with a cleaning cooling water device and a temperature sensor 2 on the thermostat condenser 1.

[0032] The cleaning and cooling water device includes a water inlet hose 3, a water inlet electromagnetic ball valve 4, a cleaning cooling water pump 5 and a condenser cleaning pipe 6, the temperature sensor 2 is arranged on the condenser 1 of the thermostat, and the condenser cleaning pipe 6 is inserted into the condenser of the thermostat 1, the temperature sensor 2 is electrically connected to the water inlet solenoid ball valve 4.

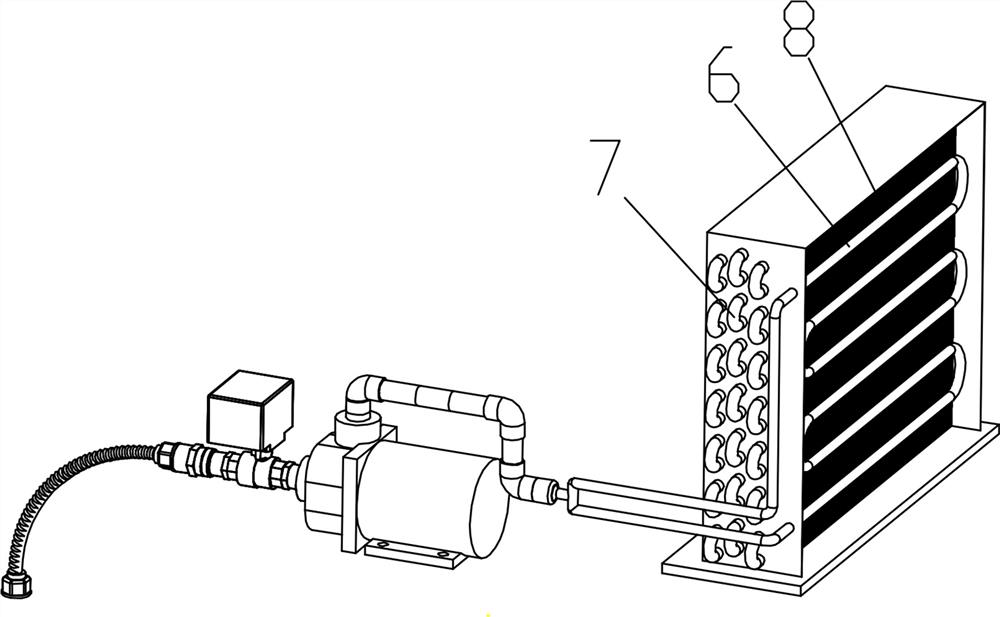

[0033] The thermostat condenser 1 is provided with a thermostat condenser copper pipe 7 and a condenser fin 8, and the condenser cleaning pipe 6 passes through the thermostat condenser 1 and is located on the front side of the thermostat condenser copper pipe 7 and the condenser fins 8. There are three rows of multi-angle holes 9 on the clea...

Embodiment 2

[0038] Embodiment 2: a device for automatic cleaning and cooling of the thermostat condenser, which is provided with a cleaning cooling water device and a temperature sensor 2 on the thermostat condenser 1.

[0039] The cleaning and cooling water device includes a water inlet hose 3, a water inlet electromagnetic ball valve 4, a cleaning cooling water pump 5 and a condenser cleaning pipe 6, the temperature sensor 2 is arranged on the condenser 1 of the thermostat, and the condenser cleaning pipe 6 is inserted into the condenser of the thermostat 1, the temperature sensor 2 is electrically connected to the water inlet solenoid ball valve 4.

[0040] The thermostat condenser 1 is provided with a thermostat condenser copper pipe 7 and a condenser fin 8, and the condenser cleaning pipe 6 passes through the thermostat condenser 1 and is located on the front side of the thermostat condenser copper pipe 7 and the condenser fins 8. There are three rows of multi-angle holes 9 on the cl...

Embodiment 3

[0045] Embodiment 3: a kind of device of automatic cleaning and cooling thermostat condenser, it is provided with cleaning cooling water device and temperature sensor 2 on thermostat condenser 1.

[0046] The cleaning and cooling water device includes a water inlet hose 3, a water inlet electromagnetic ball valve 4, a cleaning cooling water pump 5 and a condenser cleaning pipe 6, the temperature sensor 2 is arranged on the condenser 1 of the thermostat, and the condenser cleaning pipe 6 is inserted into the condenser of the thermostat 1, the temperature sensor 2 is electrically connected to the water inlet solenoid ball valve 4.

[0047] The thermostat condenser 1 is provided with a thermostat condenser copper pipe 7 and a condenser fin 8, and the condenser cleaning pipe 6 passes through the thermostat condenser 1 and is located on the front side of the thermostat condenser copper pipe 7 and the condenser fins 8. There are three rows of multi-angle holes 9 on the cleaning pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com