Highway and bridge deck pavement interlayer shear tester and method considering centrifugal force

A bridge deck paving and interlaminar shearing technology, applied in the direction of applying stable shear force to test material strength, instruments, measuring devices, etc., can solve the problem of single function, without considering the influence of centrifugal force interlaminar shear stress, It cannot effectively simulate the shear stress conditions of curved girder bridge deck roads, etc., to achieve the effect of good practicability, high degree of simulation, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

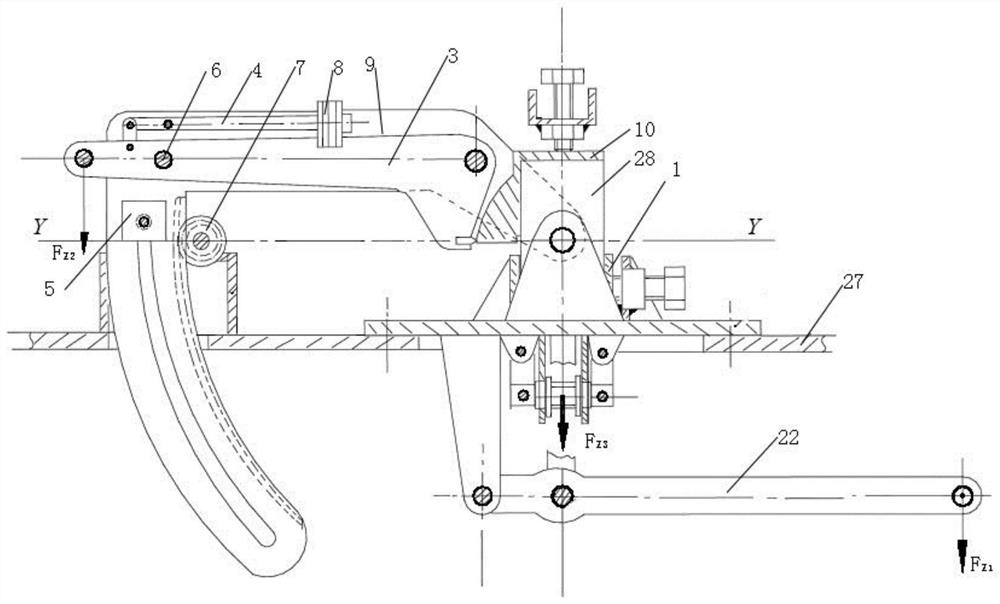

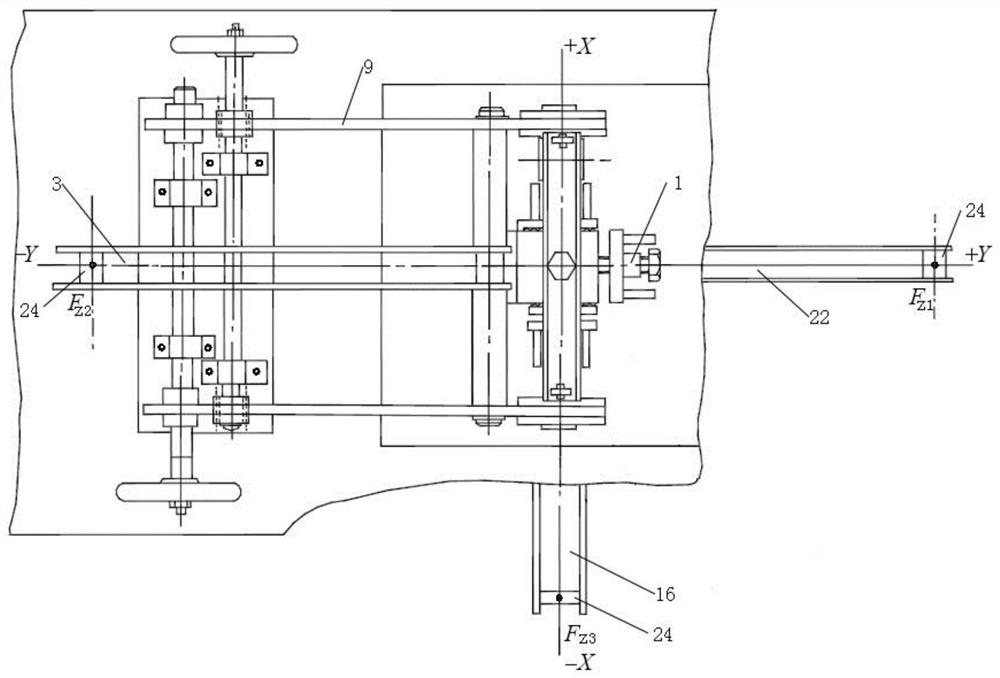

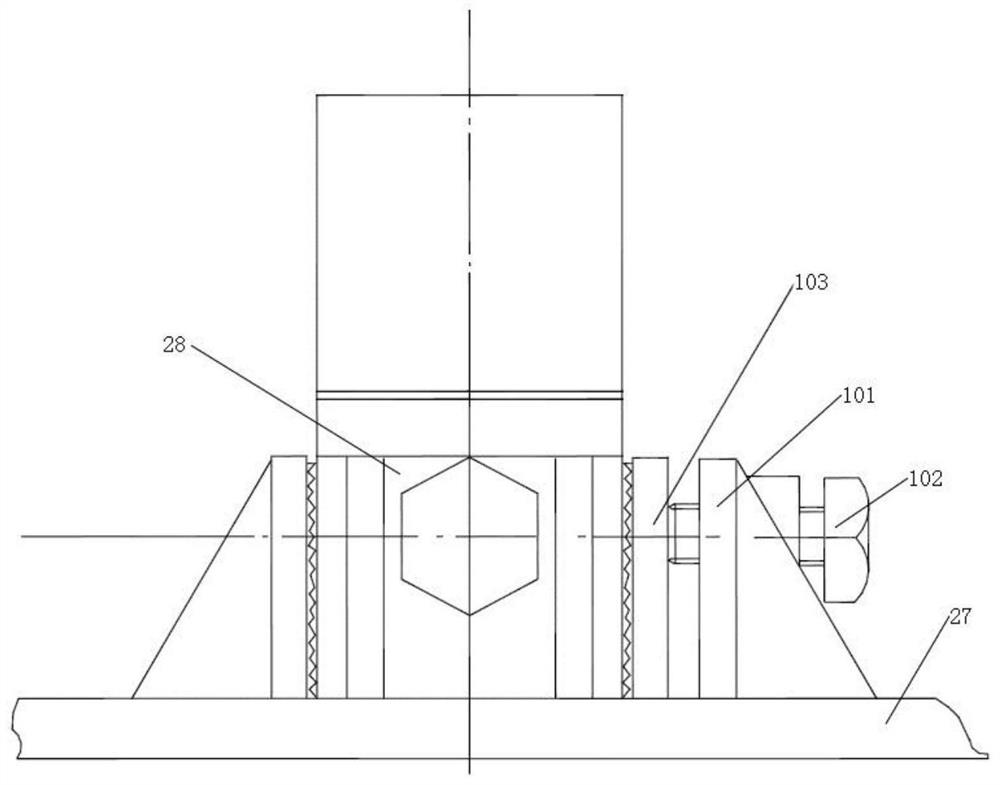

[0063] Such as Figure 1-9 As shown, a highway and bridge deck interlayer shear tester considering centrifugal force, including F Z1 Loading lever 22, F Z2 Loading lever 3, F Z3 Loading lever 16, specimen clamping device 1, angle adjustment arm 9, counterweight 8, adjustment locking device 5, self-weight balance lever 4, first pressing blade 14, second pressing blade 19, fixed pulley 2, upper beam 20 , the lower cross shaft 25, the adjusting bolt 26, the first pull rod 17, the second pull rod 21 and the fulcrum arm 23. f Z2 The loading lever 3 is hinged on the angle adjustment arm 9, and the angle adjustment arm 9 is hinged on the upper side of the main abutment surface 27, F Z1 Loading lever 22, F Z3 The loading lever 16 is hinged on the underside of the main abutment surface 27, F Z3 The loading lever 16 is located on the negative half ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com