System and method for detecting PLC effect of alloy

A detection system and alloy technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and preparation of test samples, can solve the problems that it is difficult to observe the nucleation, proliferation and space-time evolution characteristics of alloy PLC bands , to achieve the effect of strong anti-natural interference ability, simple equipment and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

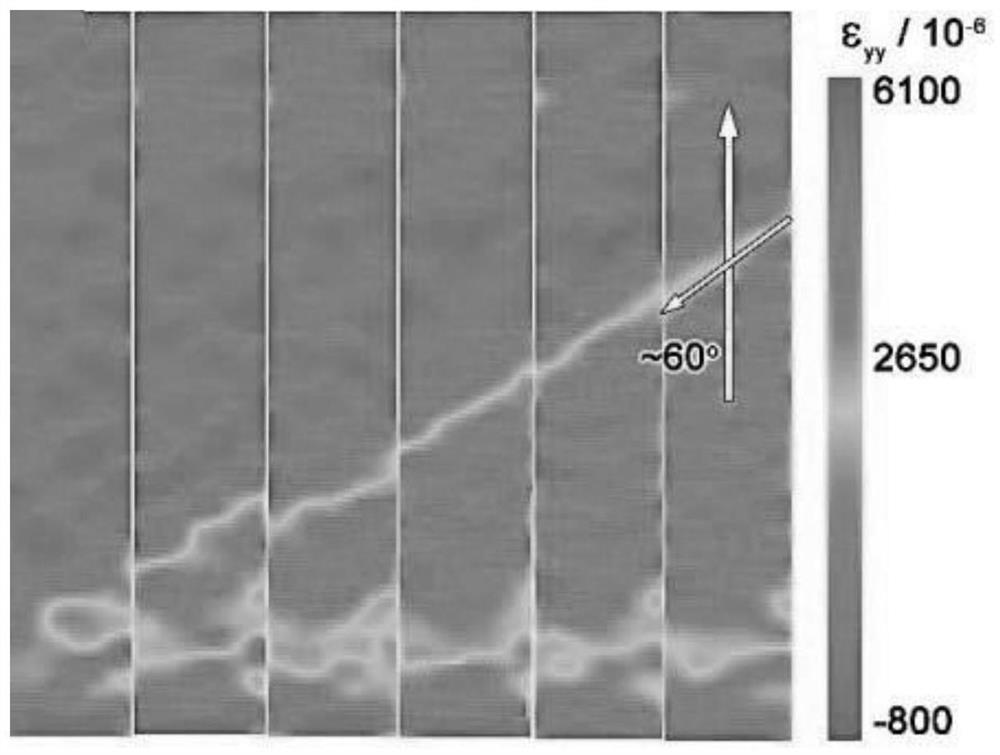

Examples

Embodiment 1

[0053] The composition (wt.%) of the alloy used in this example is as follows: Co 30%, Cr 20%, Ti 1%, Al 0.65%, W 1.5%, Mo 4%, C 0.02%, Zr 0.015%, B 0.015%, Ni in the balance.

[0054] Use the following steps to test the PLC effect:

[0055] Step (1): The above-mentioned metal material is processed into a plate-shaped tensile sample by wire electric discharge cutting, and the gauge length section of the prepared tensile sample has a size of 25mm×5mm×1.25mm;

[0056] Step (2): Evenly spray the surface of the tensile sample with a high-temperature-resistant white primer. The thickness of the white primer is 0.2mm. Put the tensile sample in a drying oven and dry it at 80°C for 15 minutes; then spray a high-temperature-resistant black paint. The black paint is randomly attached to the white primer in small spots. Put the tensile sample into the drying oven and dry it at 80°C for 10 minutes to form high-temperature scattered spots;

[0057] Step (3): Heat the heating and holding ...

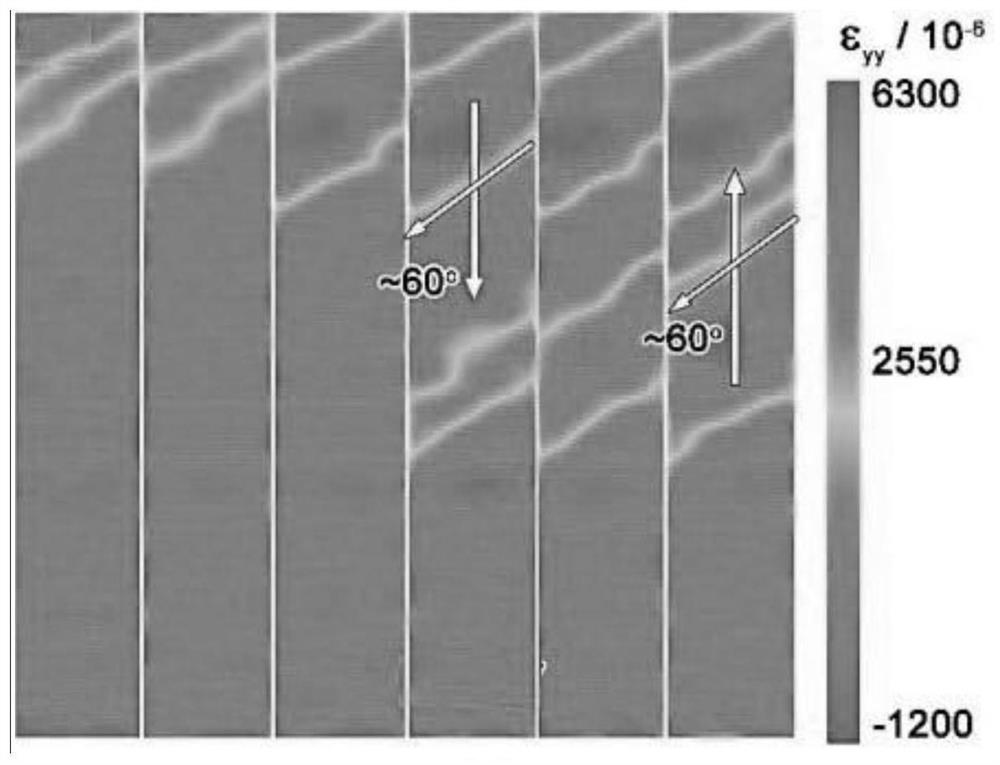

Embodiment 2

[0061] The composition (wt.%) of the alloy used in this example is as follows: Co 25%, Cr 15%, Ti 4%, Al 1.5%, W 1.5%, Mo 3%, C 0.02%, Zr 0.015%, B 0.015%, Ni in the balance.

[0062] Use the following steps to test the PLC effect:

[0063] Step (1): The above-mentioned metal material is processed into a plate-shaped tensile sample by wire electric discharge cutting, and the gauge length section of the prepared tensile sample has a size of 25mm×5mm×1.25mm;

[0064] Step (2): Spray evenly the surface of the tensile sample with a high-temperature-resistant white primer. The thickness of the white primer is 0.3 mm. Put the tensile sample in a drying oven and dry it at 100°C for 15 minutes; then spray with a high-temperature-resistant black paint , the black paint is randomly attached to the white primer in small spots, put the tensile sample into the drying oven, and dry at 100°C for 10 minutes to form high-temperature scattered spots;

[0065] Step (3): Heat the heating and ho...

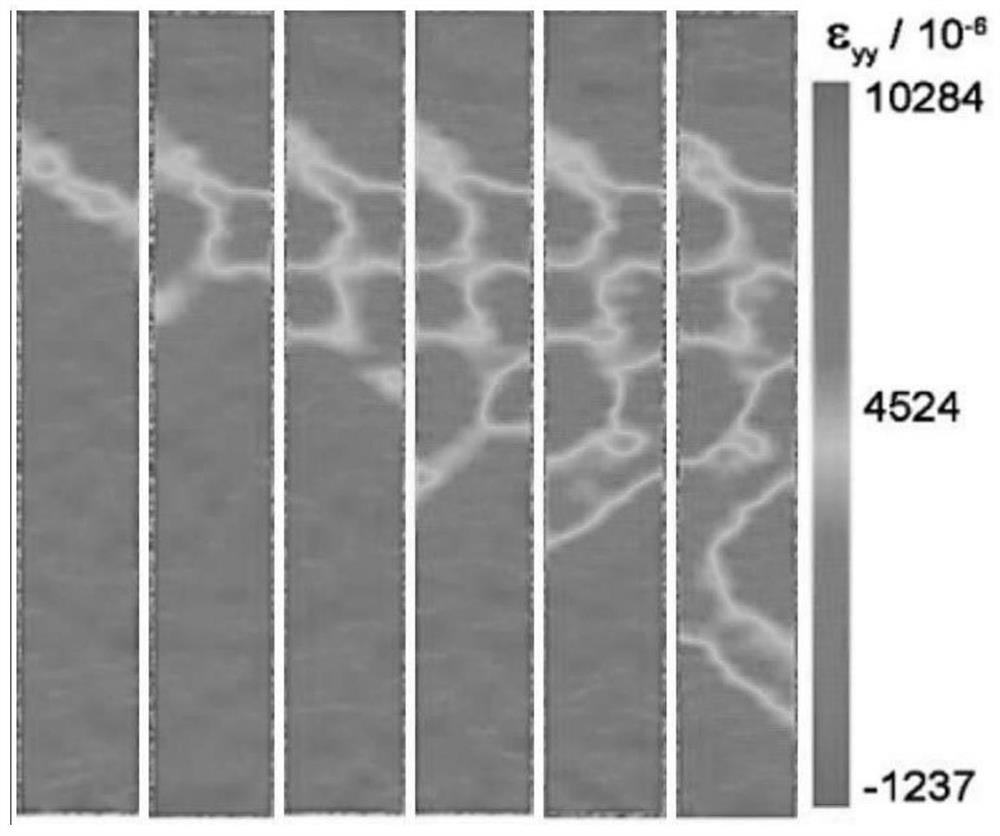

Embodiment 3

[0069] The composition (wt.%) of the alloy that adopts in the present embodiment is as follows:

[0070] Co 25%, Cr 15%, Ti 4%, Al 1.5%, W 1.5%, Mo 3%, C 0.02%, Zr 0.015%, B 0.015%, Ni in the balance.

[0071] Use the following steps to test the PLC effect:

[0072] Step (1): The metal material to be tested is processed into a plate-shaped tensile sample by WEDM, and the gauge length section of the prepared tensile sample has a size of 25mm×5mm×1.25mm;

[0073] Step (2): Spray evenly the surface of the tensile sample with a high-temperature-resistant white primer. The thickness of the white primer is 0.5 mm. Put the tensile sample in a drying oven and dry it at 150°C for 15 minutes; then spray with a high-temperature-resistant black paint , the black paint is randomly attached to the white primer in small spots, put the tensile sample into the drying oven, and dry it at 150°C for 10 minutes to form high-temperature scattered spots;

[0074] Step (3): Heat the heating and hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com