Method and device for protecting optical cable outside oil well casing

A technology for oil well casing and protective devices, which is applied in the direction of using optical devices to transmit sensing components, measuring devices, and seismology for well logging records, which can solve the problem of increasing the outer diameter of the overall casing components and occupying downhole operation time Long, can not play the role of optical cable protection, etc., to achieve the effect of improving the success rate of laying, saving the time of well occupation, and improving the efficiency of laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for protecting an optical cable outside an oil well casing, and the method specifically includes the following steps:

[0040] (1) Select two wire ropes whose length is greater than the depth of the oil well and whose diameter is greater than the diameter of the optical cable;

[0041] (2) Connect two casings, then fix the steel wire rope and optical cable on the outside of the casing along the length direction of the casing, keep the optical cable between the two steel wire ropes, and use cable ties to connect the casing collar and the middle of the casing. Wire rope and optical cable fixing;

[0042](3) On the basis of the casing in step (2), continue to connect the casing, fix the steel wire rope and optical cable on the outside of the continuous casing according to the method of step (2), repeat "continuing casing - fixing the steel wire rope and Optical cable" operation, until all the casings are connected, the optical cable and s...

Embodiment 2

[0044] This embodiment provides a protection device for an optical cable outside an oil well casing, and the protection device is used to implement the protection method in Embodiment 1. The protective device includes two steel wire ropes and stainless steel cable ties arranged side by side, wherein the diameter of the steel wire rope is 3-8mm, the length of the steel wire rope is ≥ 2km, and the cross-sectional shape of the steel wire rope can be any one of circular, oval, rectangular, and triangular. Types; the thickness or diameter of stainless steel cable ties should be greater than 1mm and less than 4mm.

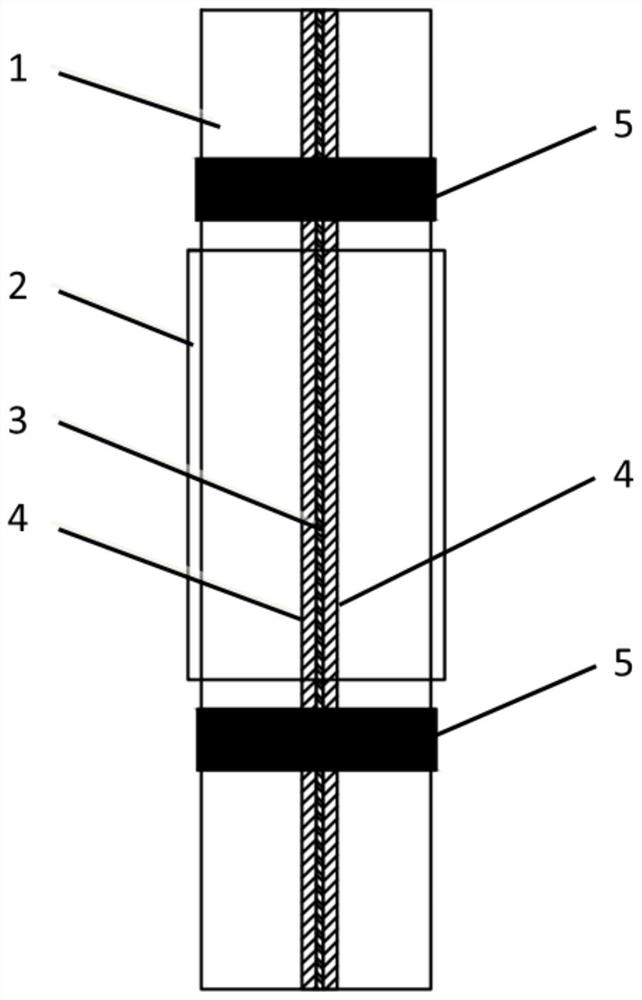

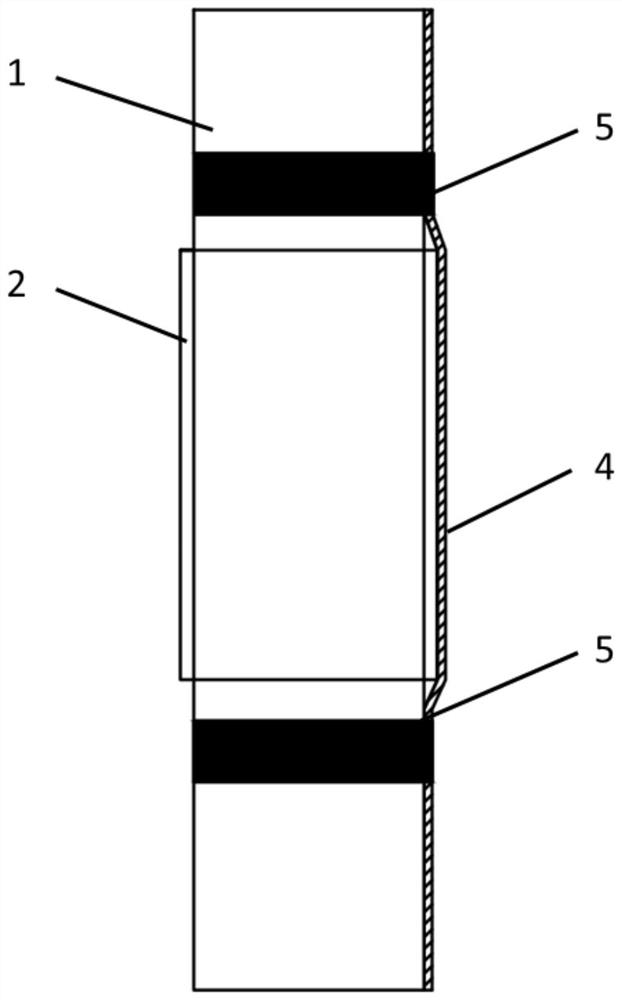

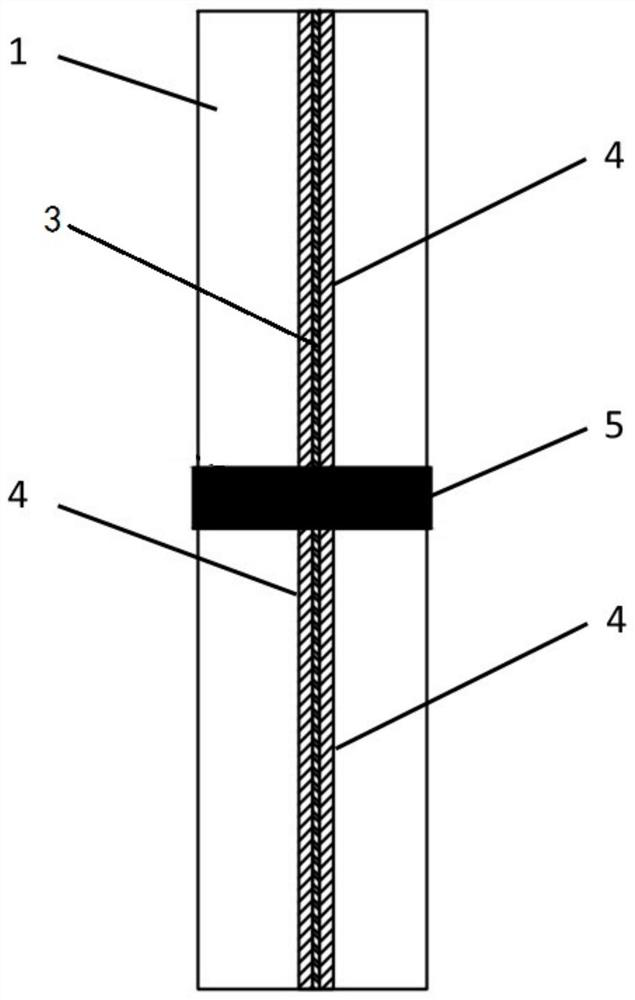

[0045] The use status of the protection device provided in this embodiment at different positions of the bushing is as follows: Figure 1-Figure 3 shown.

[0046] Such as Figure 1-Figure 3 As shown, when the protective device is in use, its layout with the casing is as follows:

[0047] The casing collar 2 is used to continue the casing 1 and is located between adjac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com