Crushing type medical intravenous infusion tube recycling machine

An intravenous infusion, pulverized technology, applied in the field of pulverized medical intravenous infusion tube recycling machines, can solve the problems of large occupied space, easy slipping of medical staff and patients, and influence of walking of medical staff and patients, etc., and achieves the effect of reducing the occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

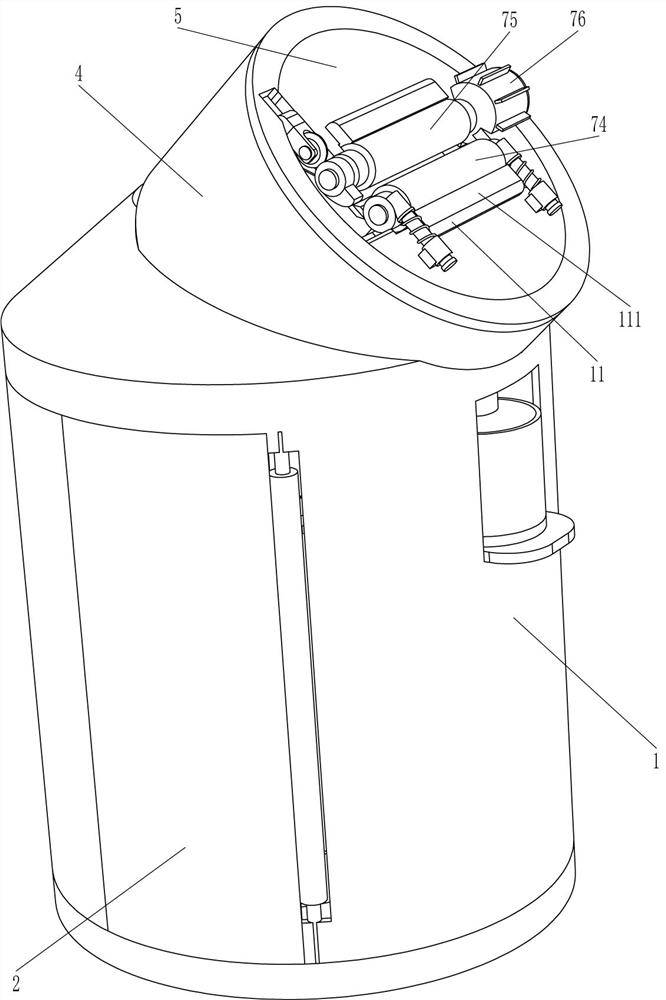

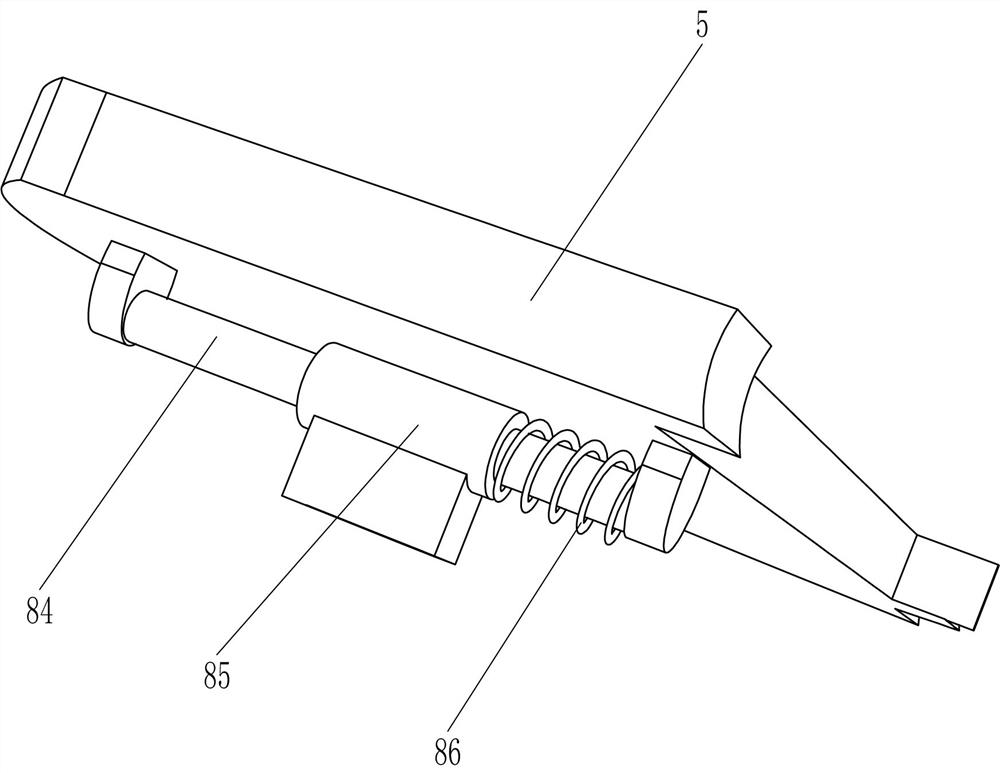

[0023] A crushing type medical venous infusion tube recovery machine, such as Figure 1-5 As shown, it includes a placement tube 1, a hinged plate 2, a collection frame 3, a mounting pipe 4, a mounting plate 5, a hopper 6, a feeding mechanism 7 and a cutting mechanism 8, and the front part of the placement tube 1 is hingedly connected with a hinged plate 2. A collection frame 3 is placed inside the tube 1, and the top of the tube 1 is embedded with an installation tube 4, the bottom left side of the installation tube 4 is connected with a discharge hopper 6, the top of the installation tube 4 is connected with an installation plate 5, and the top of the installation plate 5 is installed with a feeding Mechanism 7, a cutting mechanism 8 is installed on the bottom of the mounting plate 5, and the feeding mechanism 7 is connected with the cutting mechanism 8 through transmission.

[0024] The feeding mechanism 7 includes a sliding sleeve 71, a slide bar 72, a first spring 73, a f...

Embodiment 2

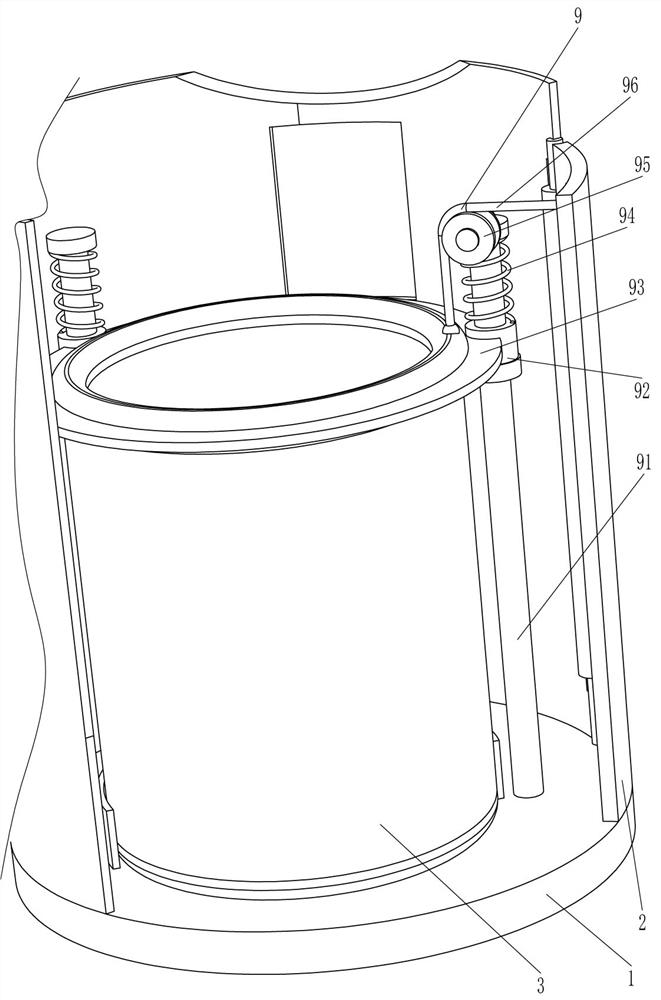

[0028] On the basis of Example 1, such as figure 2 Shown, also comprise pocket pressing mechanism 9, and pocket pressing mechanism 9 comprises vertical bar 91, guide ring 92, pressure ring 93, the 3rd spring 94, guide wheel 95 and stay cord 96, collection frame 3 front and back Both sides are placed in the top of the tube 1 and are connected with a vertical rod 91, and a guide ring 92 is slidably connected to the vertical rod 91, and a pressure ring 93 is connected between the two guide rings 92, and the top of the guide ring 92 is connected with the top of the vertical rod 91. The third spring 94 is connected therebetween, the top of the front side vertical bar 91 is rotatably connected with a guide wheel 95, the top of the pressure ring 93 is connected with a stay cord 96, and the top of the stay cord 96 goes around the guide wheel 95 and is connected to the inner side of the hinge plate 2.

[0029] When the hinged plate 2 is opened, the pull cord 96 can pull the pressure r...

Embodiment 3

[0031] On the basis of Example 2, such as image 3 As shown, it also includes a waste liquid collection mechanism 10. The waste liquid collection mechanism 10 includes a liquid collection cup 101, a grid plate 102, a liquid outlet bucket 103 and a placement plate 104. There is a port on the right side of the placement cylinder 1. Slidingly connected with a placement plate 104, the top of the placement plate 104 is connected with a liquid collection cup 101, the right side of the discharge hopper 6 is connected with a grid plate 102, the right side of the grid plate 102 is connected with a liquid outlet 103, and the liquid outlet 103 Located on the upper side of the liquid collection cup 101.

[0032] The residual medical solution in the intravenous infusion tube flows into the outlet hopper 103 through the grid plate 102, and the residual medical solution in the outlet hopper 103 then flows into the liquid collection cup 101, so that the residual medical solution can be collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com