A laser engraving equipment for mobile phone antenna processing

A mobile phone antenna and laser engraving technology, which is applied to metal processing equipment, antennas, welding equipment, etc., can solve problems such as eye injury, processing deviation, and easily burnt operators of molded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

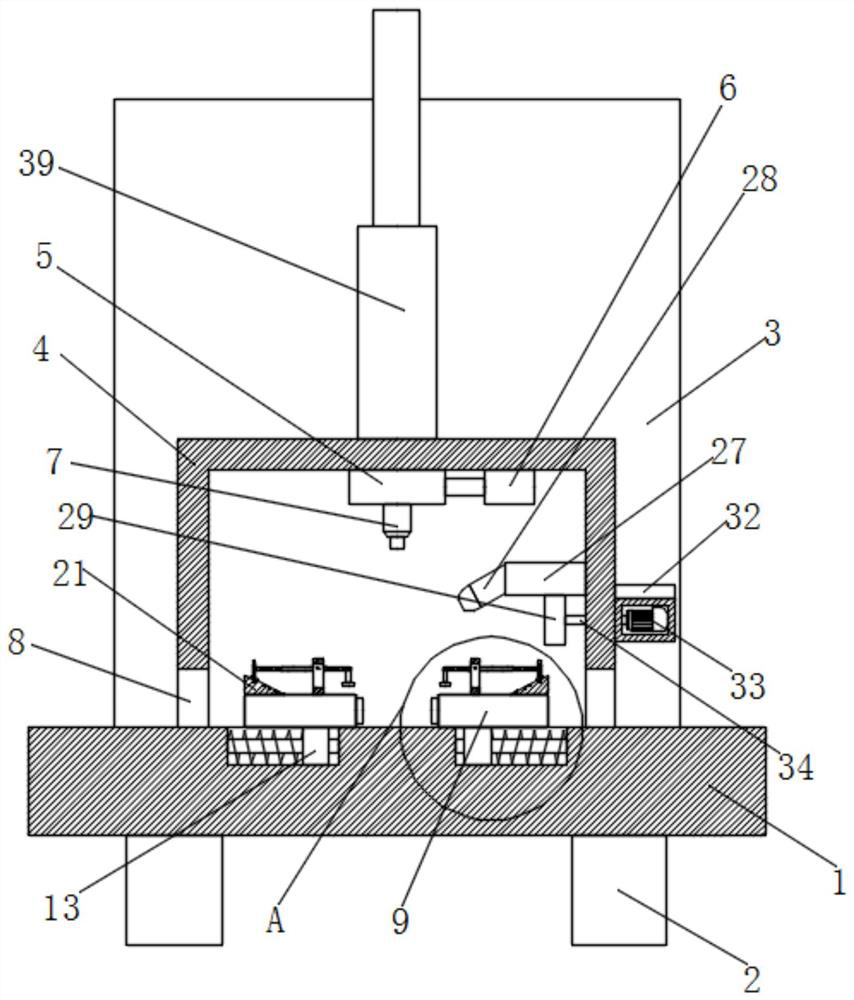

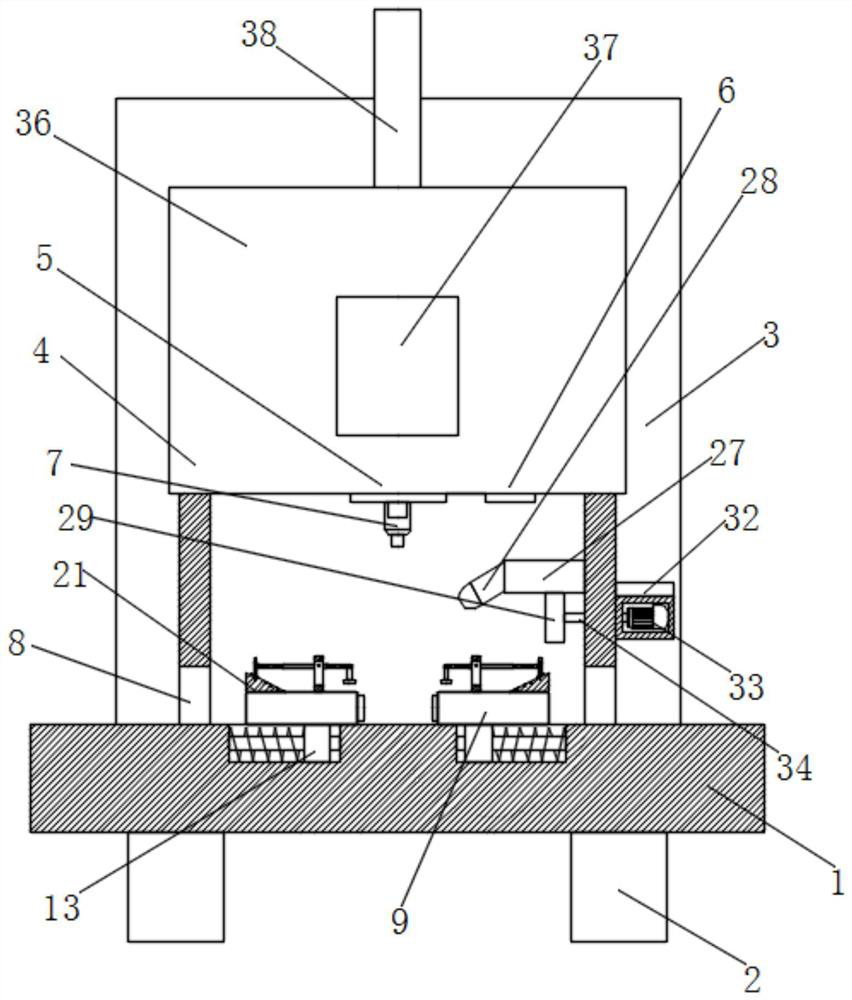

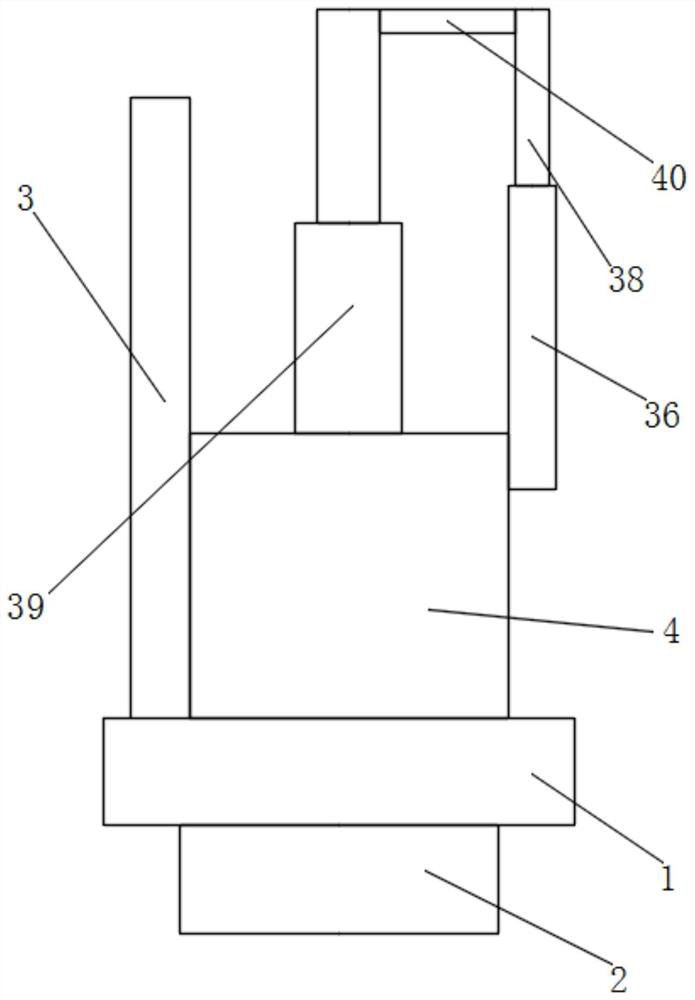

[0029] refer to Figure 1-6 , a laser engraving device for mobile phone antenna processing, comprising a base plate 1, two brackets 2 are symmetrically fixedly installed on the bottom of the base plate 1, side plates 3 are fixedly installed on the top of the base plate 1, and a protective cover is fixedly installed on the top of the base plate 1 4. A control box 5 is slidably installed on the top inner wall of the protective cover 4, a laser processing head 7 is movably installed on the bottom of the control box 5, and a first electric push rod 6 is fixedly installed on the top inner wall of the protective cover 4. The output shaft of the rod 6 is fixedly connected with the control box 5, and the protective cover 4 is symmetrically provided with two through holes 8, and the top of the bottom plate 1 is slidably mounted with two splints 9, the two splints 9 are matched, and the two splints 9 The first connecting plate 18 is movably installed on the top, the bottom of the two fi...

Embodiment 2

[0040] refer to Figure 1-6 , a laser engraving device for mobile phone antenna processing, including a base plate 1, the bottom of the base plate 1 is symmetrically fixed with two brackets 2 by welding, the top of the base plate 1 is fixedly installed with a side plate 3 by welding, and the top of the base plate 1 is fixed by welding. A protective cover 4 is fixedly installed by welding, a control box 5 is slidably installed on the top inner wall of the protective cover 4, a laser processing head 7 is movably installed on the bottom of the control box 5, and a first electric motor is installed on the top inner wall of the protective cover 4 by screws. Push rod 6, the output shaft of the first electric push rod 6 is fixedly connected with the control box 5, two through holes 8 are symmetrically opened on the protective cover 4, and two splints 9 are symmetrically slidably installed on the top of the bottom plate 1, and the two splints 9 Matched, the tops of the two splints 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com