Intelligent vehicle washer and vehicle washing method

A car washing machine, an intelligent technology, applied in the field of car washing machines, can solve the problems that can only be installed in and cannot meet the installation requirements of car washing shops on the facade of automobiles, and achieve the effects of preventing left and right shaking, improving car washing experience, and saving time and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

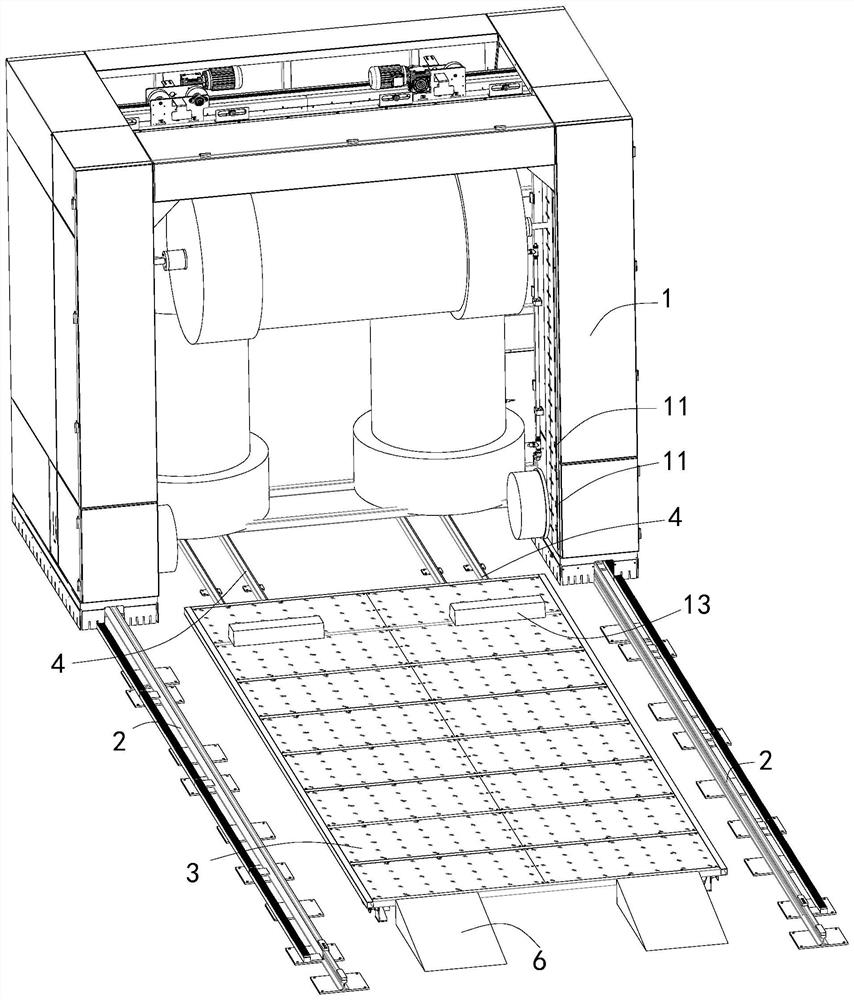

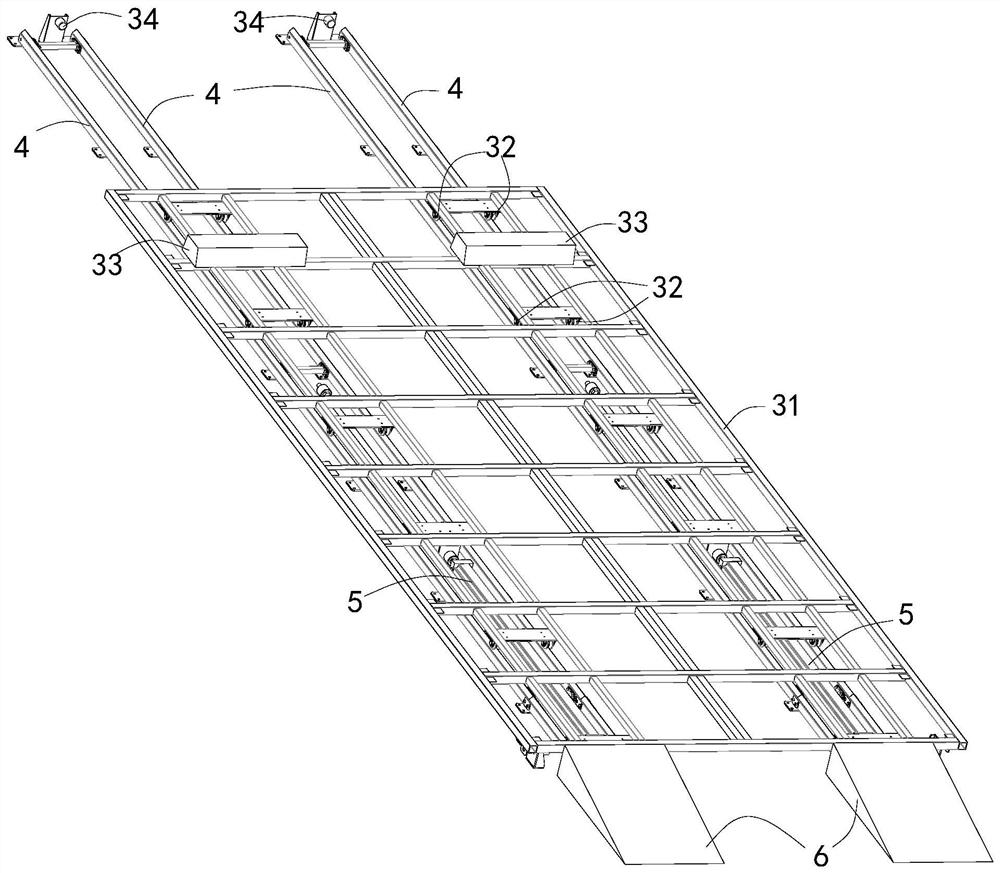

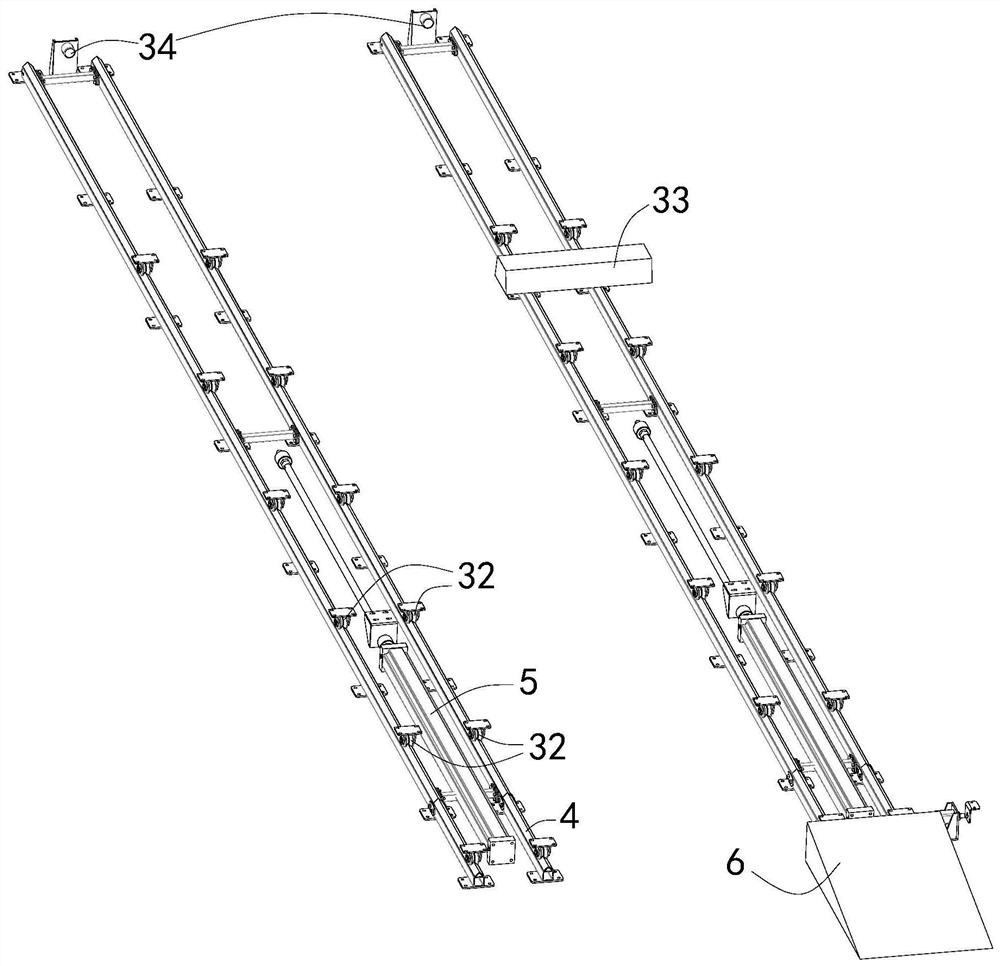

[0041] Such as figure 1 shown, combined with figure 2 , the intelligent car washing machine of the present invention comprises a gantry traveling mechanism 1 , a first guide rail 2 , a vehicle carrying platform 3 , a second guide rail 4 , a driving mechanism 5 and a slope pad 6 .

[0042] The first guide rail 2 is arranged on the ground to provide a guiding function, and the prior art can be adopted.

[0043] Wherein, the gantry traveling mechanism 1 is arranged on the first guide rail 2 and is rollingly connected with it. The gantry traveling mechanism 1 has its own driving device and moves forward and backward along the first guide rail 2 . Specifically, the gantry traveling mechanism 1 is integrated with a double vertical roller brush mechanism for car washing, a horizontal roller brush mechanism for car washing roof, a double wheel hub brush mechanism and a high-pressure spray system. The above belongs to the prior art and will not be repeated here. Specifically, the tw...

Embodiment 2

[0051] This embodiment is basically the same as the first embodiment, except for the driving mechanism 5 .

[0052] The driving mechanism 5 of this embodiment includes a ball screw pair and a servo motor, the ball screw pair is respectively connected to the vehicle carrying platform 3 and the second guide rail 4, and the servo motor drives the ball screw pair.

Embodiment 3

[0054] This embodiment is basically the same as the first embodiment, except for the driving mechanism 5 .

[0055] The driving mechanism 5 of the present embodiment includes a gear, a rack and a motor, the rack is arranged in parallel with the second guide rail 4, the gear and the rack are meshed and are rotatably connected with the vehicle carrying platform 3, and the motor is fixed with the vehicle carrying platform 3 and connected with the gear Drive connection.

[0056] The car washing method of the present invention is introduced below:

[0057] S1 will be parked on the vehicle carrying platform 3 . Specifically, the vehicle is driven onto the vehicle carrying platform 3 through the two slope pads 6 and parked at the stopper 33 . Next, the gantry traveling mechanism 1 moves along the front of the vehicle to the rear of the vehicle and detects the length C of the vehicle and the parking position through the laser through-beam sensor 11 .

[0058] S2, start car washing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com