Rapid boarding and alighting system for vacuum pipeline maglev train

A technology of maglev train and vacuum pipeline, applied in the field of rail transit, can solve the problems of difficult isolation and sealing, occupying a large volume, increasing train load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

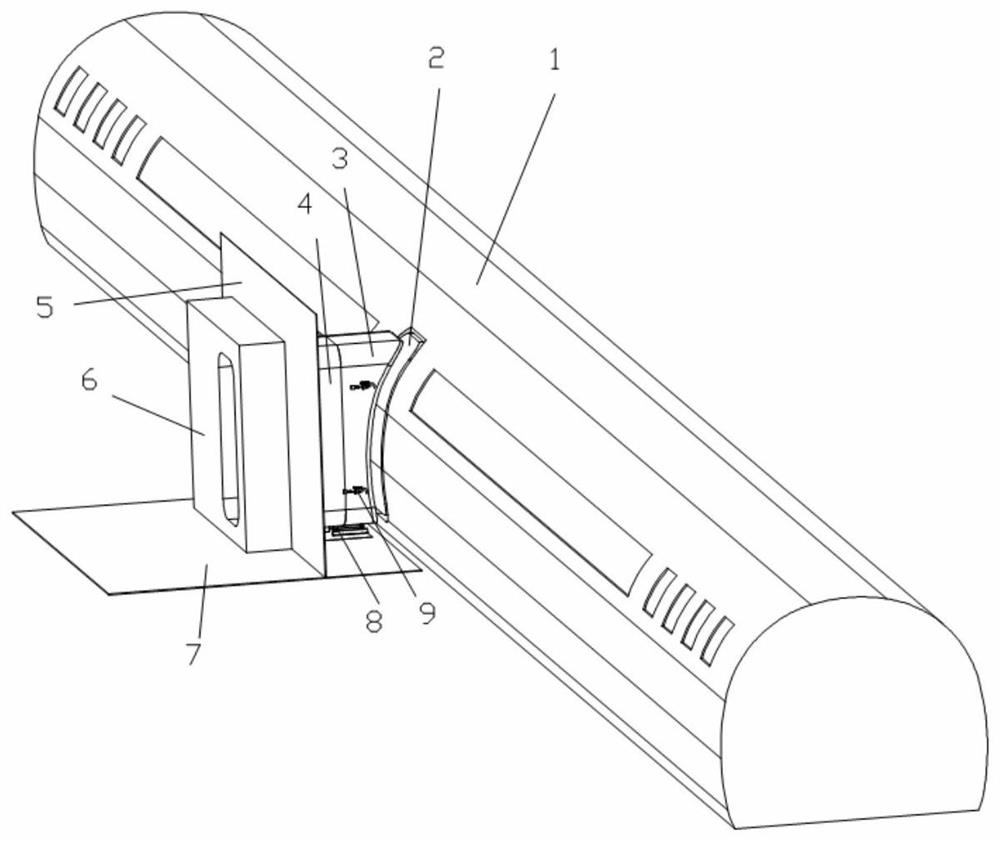

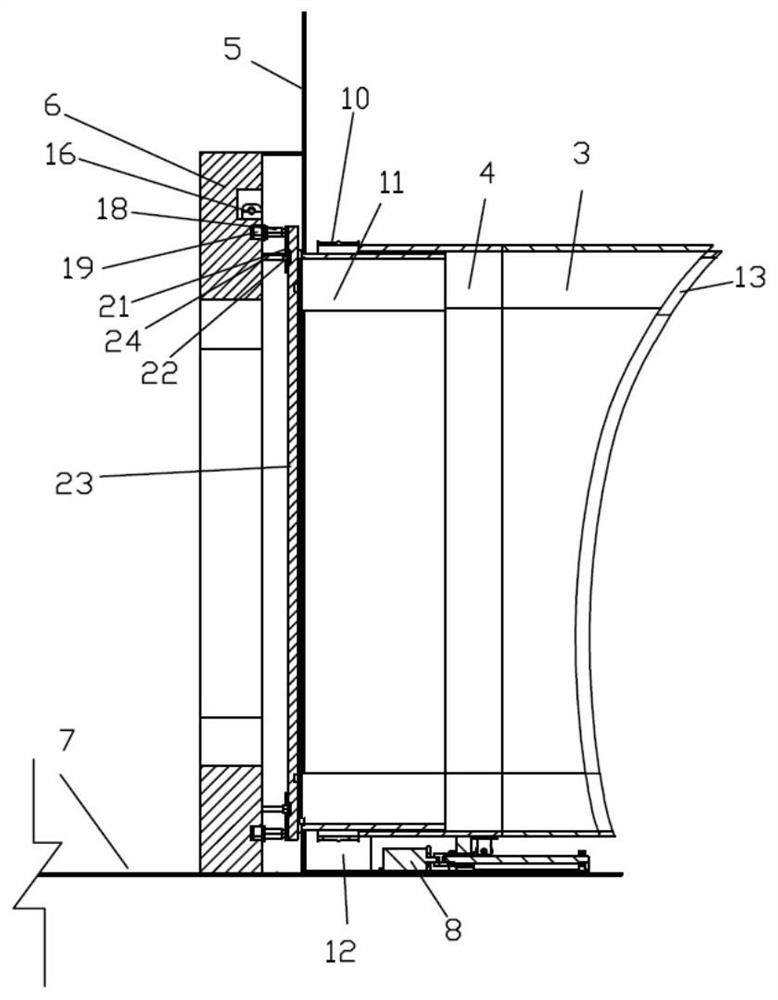

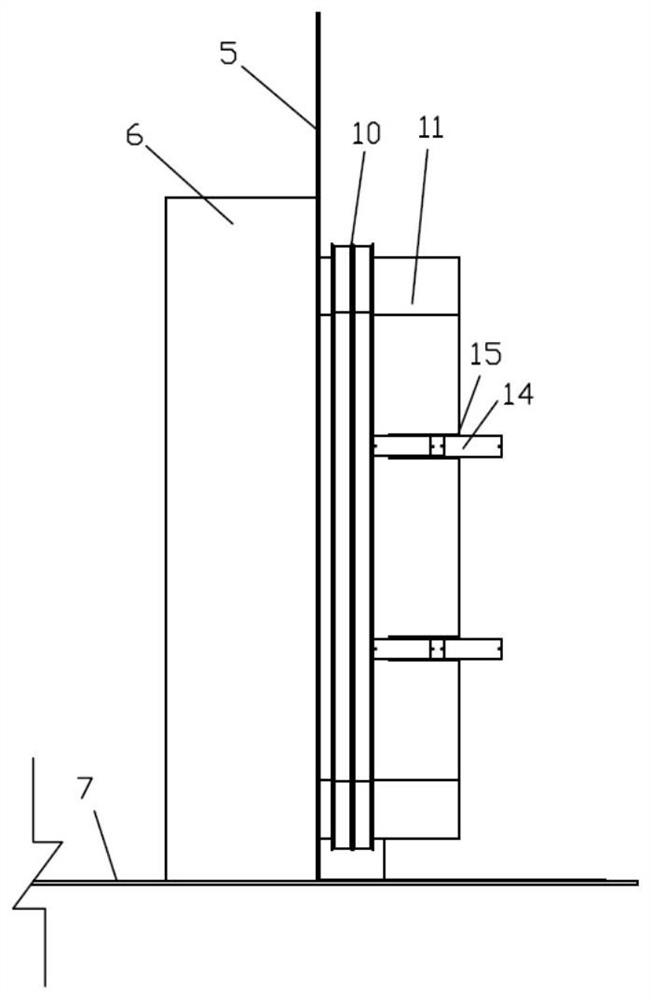

[0032] When the train 1 of the present embodiment travels through the vacuum pipe wall 5, when it is connected at a station, it is as follows: figure 1As shown, it is used for the fast boarding and unloading system of the vacuum tube maglev train, see figure 2 , including a fixed channel 11 fixedly connected to the platform 6 and a moving channel 4 that is sealed and sleeved on the fixed channel to form a horizontal movement pair, and a support block 12 is placed between the fixed channel 11 and the platform ground 7 . The entrance of the platform 6 corresponding to the fixed channel 11 is equipped with a sealed isolation door 23 driven by a translation mechanism. One end of the moving channel 4 adjacent to the train 1 has an arc-shaped port connecting port 3 matching the outer door 2 of the train. The bottom of the moving channel 4 passes through The rollers are supported on the platform ground 7 track towards the outer door 2 of the train, and are connected with the transla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com