A batch processing production transfer transmission mechanism for materials

A technology of batch processing and transmission mechanism, applied in the directions of transportation and packaging, motor vehicles, support parts, etc., can solve the problems of inconvenient transfer of forklifts, inconvenient access to materials and inconvenient forklift operations, etc. Easy to operate, convenient for feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

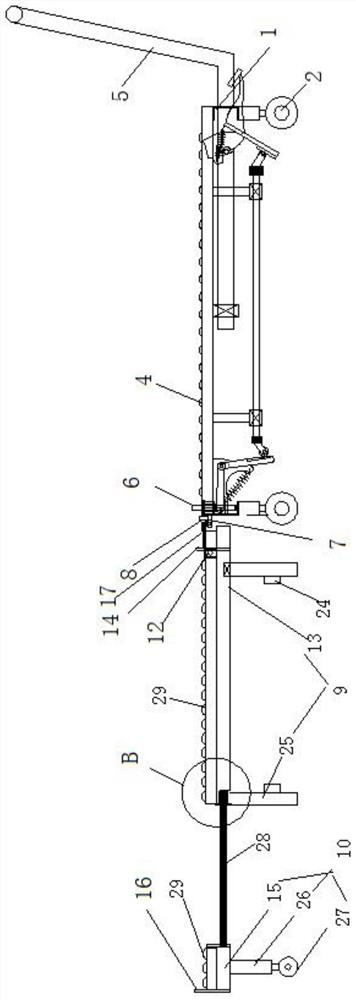

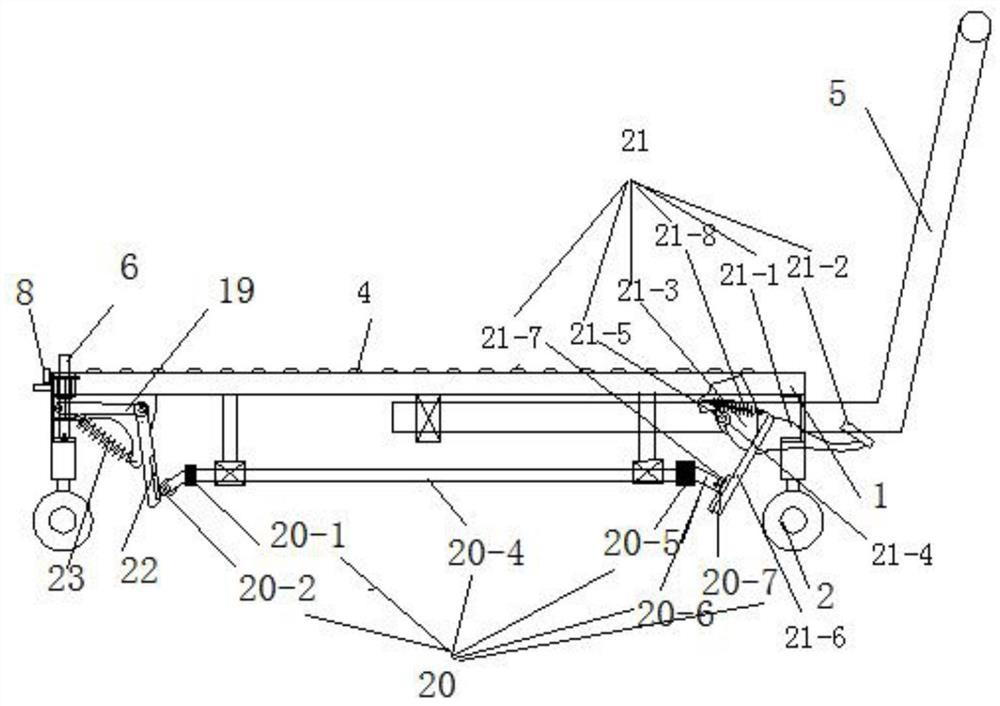

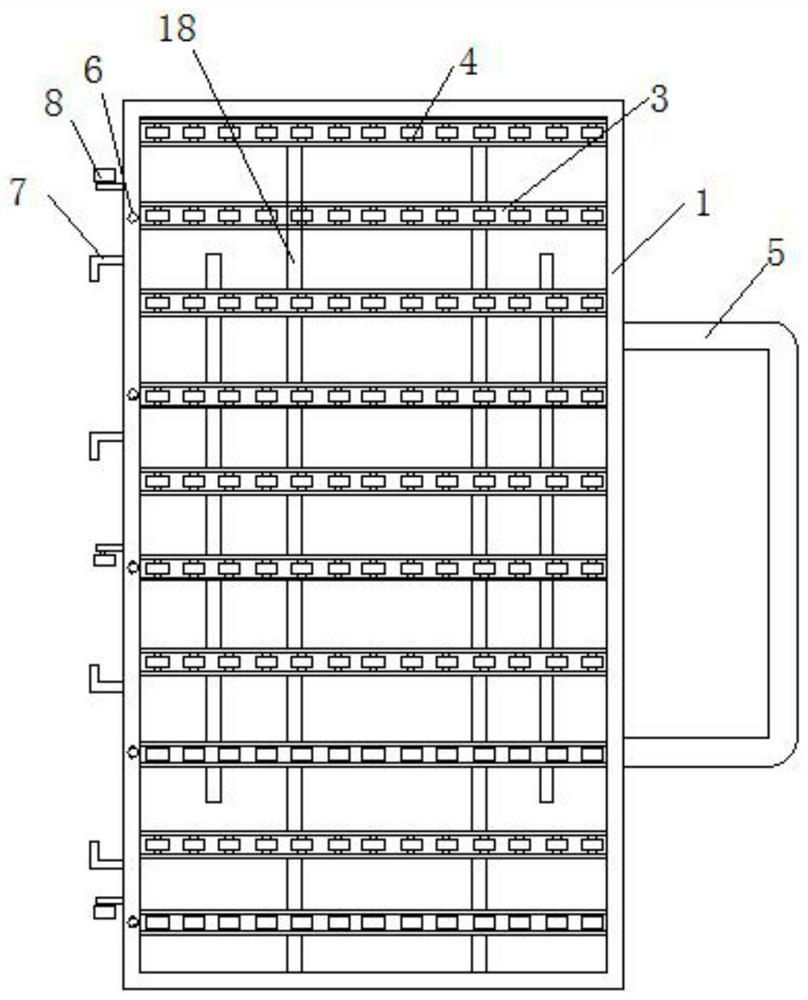

[0025] See attached picture.

[0026] A transfer transmission mechanism for mass processing and production of materials, including a transfer trolley and a material receiving rack that is used in conjunction with the transfer trolley. The upper pavement is provided with longitudinally spaced guide beams 3, and the middle part of the guide beams 3 is provided with guide grooves, and spaced rollers 4 are installed in the guide grooves. There are a plurality of spaced positioning holes distributed on the end face, and the positioning holes are respectively guided and installed with movable stop shafts 6, and the outer end surface of the vehicle frame at the end of the stop shaft 6 is also provided with spaced hooks 7 and guide wheels 8; The frame includes multiple sets of support frame units arranged side by side. The support frame units include a fixed support frame 9 and an adjustable support frame 10 respectively. Corresponding to the connection, the feed end of the fixed sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com