3D printing titanium alloy heat insulation pad

A 3D printing and thermal insulation pad technology, applied in the field of satellite structures, can solve the problems of weight reduction and low thermal insulation efficiency of titanium alloy thermal insulation pads, and achieve the effects of improving local strength, improving weight reduction efficiency, and shortening material preparation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

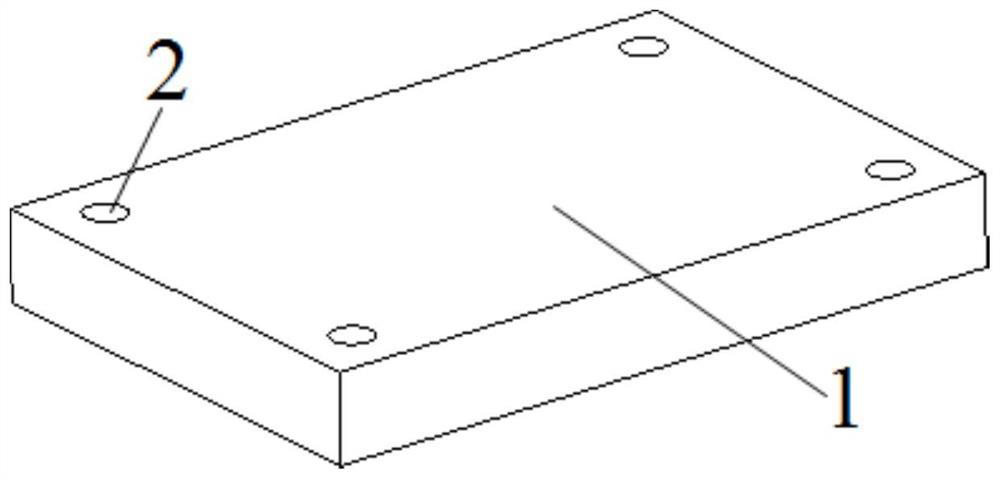

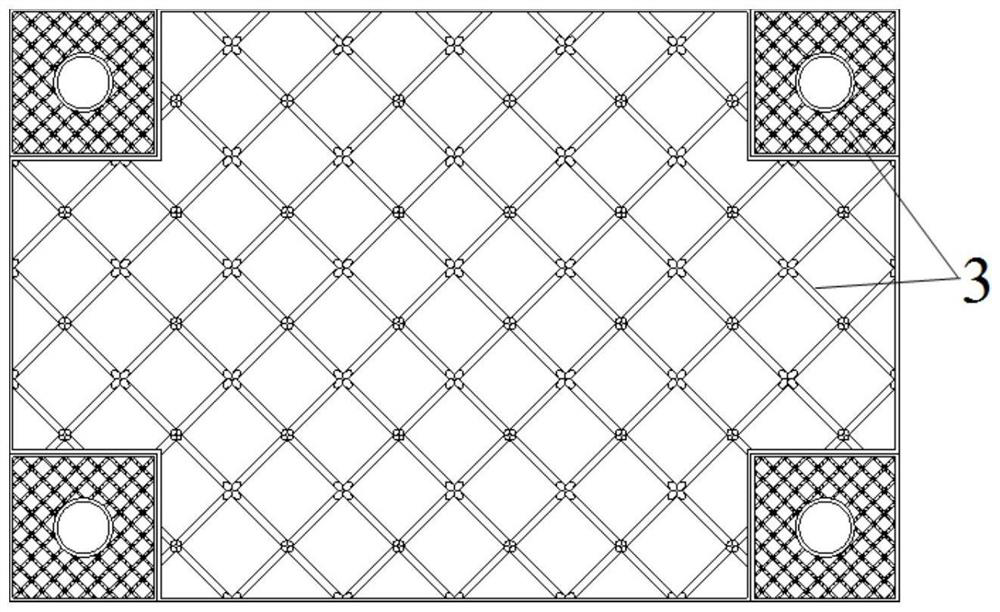

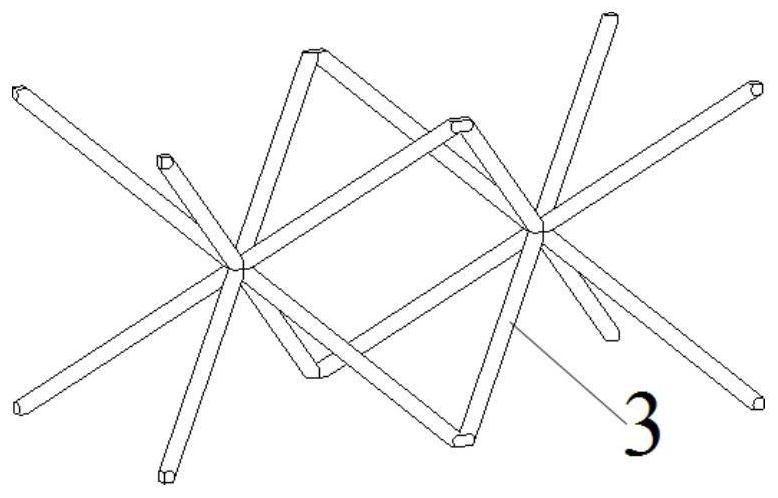

[0020] Such as figure 1 , 2 As shown in and 3, this embodiment includes: a housing 1, a through hole 2, and a lattice structure 3.

[0021] In this embodiment, the dot matrix filling cavity is a thin-walled cavity structure, and the dot matrix structure is filled in the cavity, and the through hole 2 is a bolt connection interface.

[0022] Among them, the heat insulation pad is a hexahedron with regular shape, and the two largest parallel surfaces are the installation surfaces. The shell 1 is used to provide the installation surface and wrap the internal lattice structure. The shell 1 has a certain thickness and can withstand a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rod diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com