Hoisting handling flat trolley

A flatbed truck and fixed plate technology, applied in the direction of the lifting device, etc., can solve the problems of small application range, cargo dumping, and force without side protection, etc., to achieve the effects of not being easy to slide and shift, preventing cargo dumping, and stabilizing the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

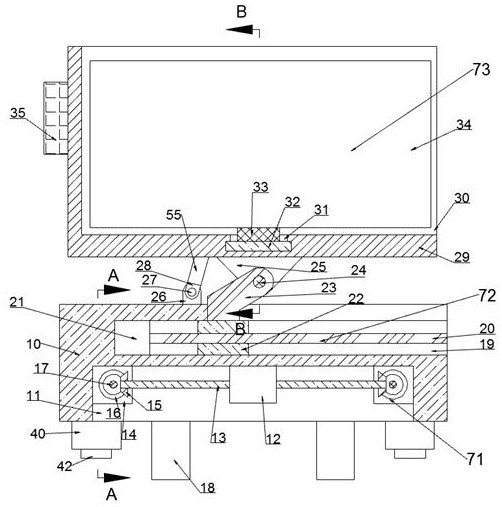

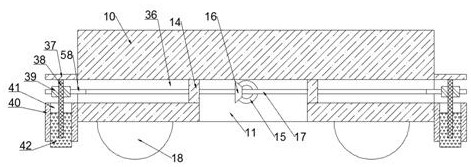

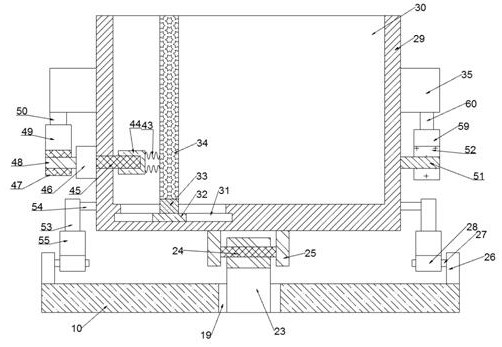

[0015] Combine below Figure 1-3 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0016] combined with Figure 1-3The lifting and handling flatbed truck includes a housing 10, the housing 10 is provided with a support cavity 11 with an opening facing downward, and a support device 71 is provided in the support cavity 11, and the support device 71 includes a support Motor 12, the support motor 12 is fixedly arranged on the inner wall of the upper side of the support cavity 11, and the left and right ends of the support motor 12 are respectively rotated to be provided with a support motor shaft 13, and the two support motor shafts 13 are left and right symmetrical, One end of the supporting motor shaft 13 away from the supporting motor 12 is fixedly provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com