Medium and fermentation method for increasing ectoine production of Corynebacterium glutamicum

A technology of Corynebacterium glutamicum and tetrahydropyrimidine, applied in the field of bioengineering, can solve problems such as restricting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Corynebacterium glutamicum CG-ECT3 is cultivated according to the cultivation and fermentation conditions disclosed in CN110699310A, the inoculum size, and the way of supplementing sugar, and the seed medium and fermentation medium adopt the aforementioned culture medium of the present invention.

[0088] The medium is:

[0089] Seed medium (g / L): peptone 4.0; yeast powder 2.0; sodium chloride 5.0; disodium hydrogen phosphate 2.5; glucose 5.0; corn steep liquor 0.1. Adjust the pH to 7.0±0.3 with liquid ammonia.

[0090] Fermentation medium: (g / L): glucose 20; (NH4) 2 SO 4 15; KH 2 PO 4 1;K 2 HPO 4 1; MgSO 4 0.25; Biotin 0.2×10 -3 ; bubble enemy 0.25L; corn steep liquor 12.5; KCl 1.9; L-aspartic acid 3; compound trace elements 1mL (compound trace elements: FeSO 4 ·7H 2 O 16.4 g; MnSO 4 ·H 2 O 100mg; CuSO 4 200mg; ZnSO 4 ·7H 2 O 1g; unit: / L).

[0091] Seed culture: Corynebacterium glutamicum CG-ECT3 was cultured overnight on BHI plates. Pick a singl...

Embodiment 2

[0095] Primary seed medium (g / L): peptone 4.0, yeast powder 2.0, sodium chloride 5.0, disodium hydrogen phosphate 2.5, glucose 5.0, corn steep liquor 0.1. Adjust the pH to 7.0±0.3 with liquid ammonia.

[0096] Secondary seed medium (g / L): glucose 18; (NH 4 ) 2 SO 4 10; KH 2 PO 4 1;K 2 HPO 4 1; MgSO 4 0.25; Biotin 0.2×10 -3 ; corn steep liquor 15; KCl 1.9; compound trace elements 0.5mL (FeSO 4 ·7H 2 O 16.4 g; MnSO 4 ·H 2 O100mg; CuSO 4 200mg; ZnSO 4 ·7H 2 O 1g; unit: / L); adjust the pH to 7.0±0.3 with liquid ammonia.

[0097] Fermentation medium: (g / L): glucose 20; (NH 4 ) 2 SO 4 18; KH 2 PO 4 1;K 2 HPO 4 1; MgSO 4 0.25; Biotin 0.2×10 -3 ; bubble enemy 0.25L; corn steep liquor 12.5; KCl 1.9; L-aspartic acid 3; compound trace elements 1mL (compound trace elements: FeSO 4 ·7H 2 O 16.4 g; MnSO 4 ·H 2 O 100mg; CuSO 4 200mg; ZnSO 4 ·7H 2 O 1g; unit: / L). The concentration of glucose in feeding feed is 400g / L, and the pH is adjusted to 7.0±0....

Embodiment 3

[0105] The medium is the same as in Example 2 above.

[0106] The recombinant Corynebacterium glutamicum CG-ECT3 strain in the glycerol tube was inoculated into the primary seed medium at an inoculation amount of 0.5% for expansion cultivation, the liquid volume: 40%; temperature: 30.0°C; shaking frequency: 120rpm ;Cultivation time: 12h, obtain first-class species.

[0107] The first-class species was inoculated into the second-class seed medium with 1% inoculum amount for cultivation, the liquid volume: 40%; temperature: 30.0°C; shaking frequency: 120rpm; cultivation time: 12h, and the second-class species were obtained.

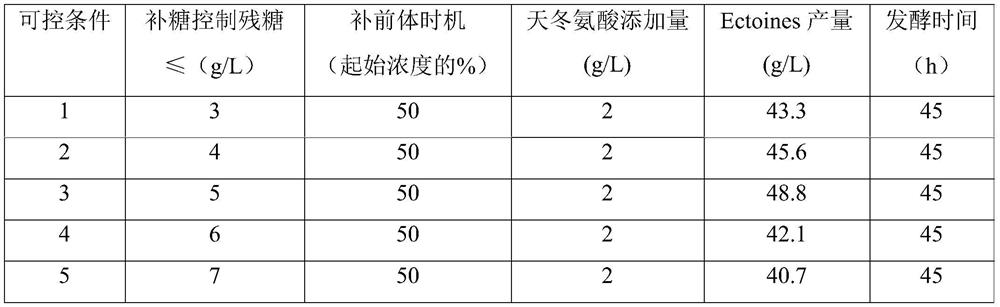

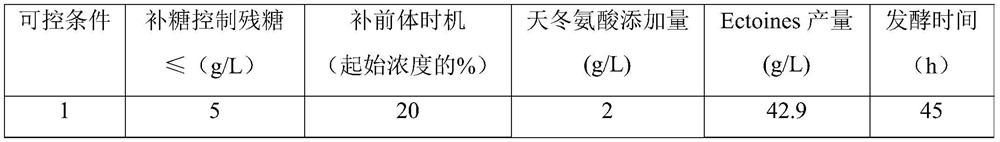

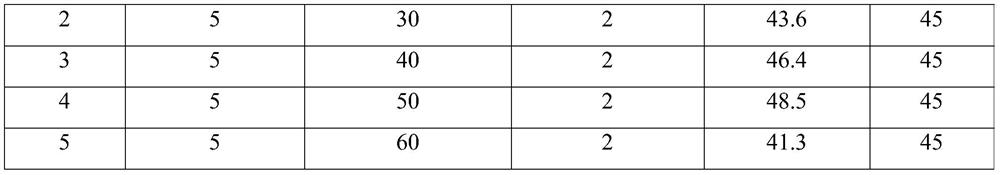

[0108] The secondary species is inoculated in the fermentation medium (10L fermenter) by 10% inoculum size and cultivated, liquid filling capacity: 60%; control temperature: 30.0°C; pressure 0.09MPa; maintain pH7.0 with liquid ammonia (in supplementary Adjust the pH after adding glucose); time 45h; volume 60M 3 / h; during the whole fermentation process, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com