Type 2 streptococcus suis high-intensity fermentation medium and application

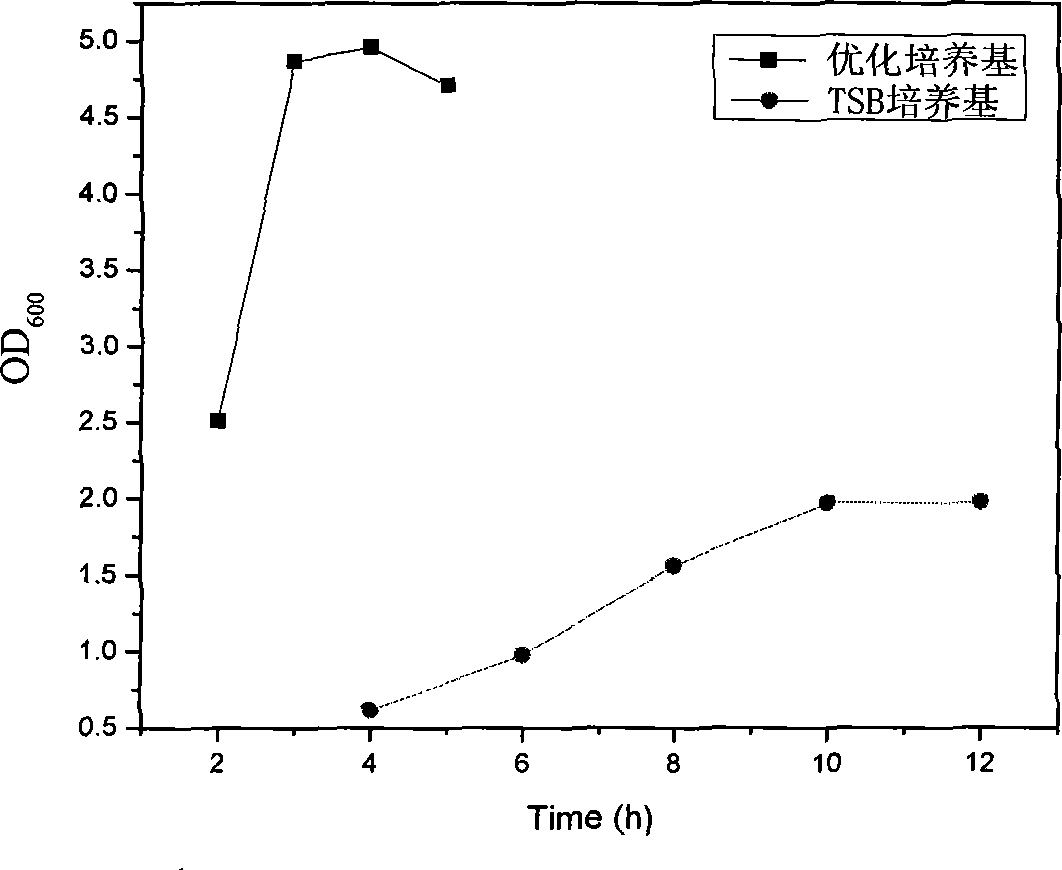

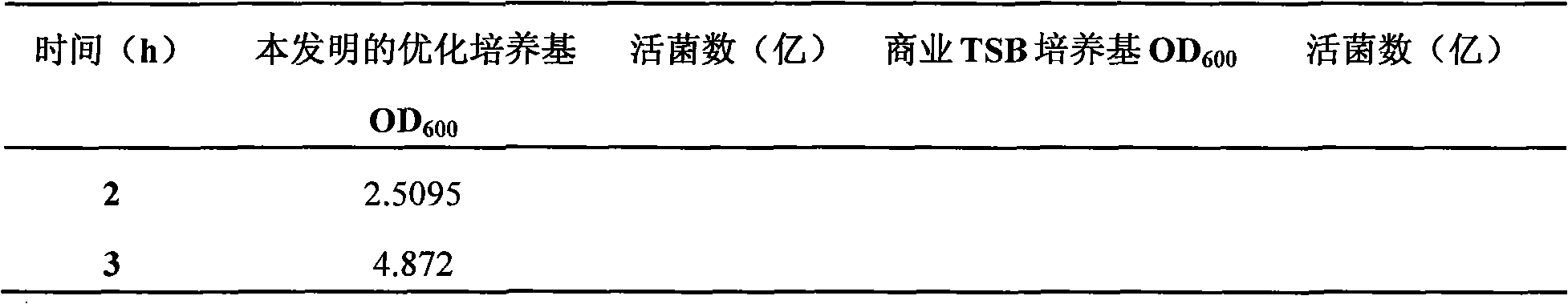

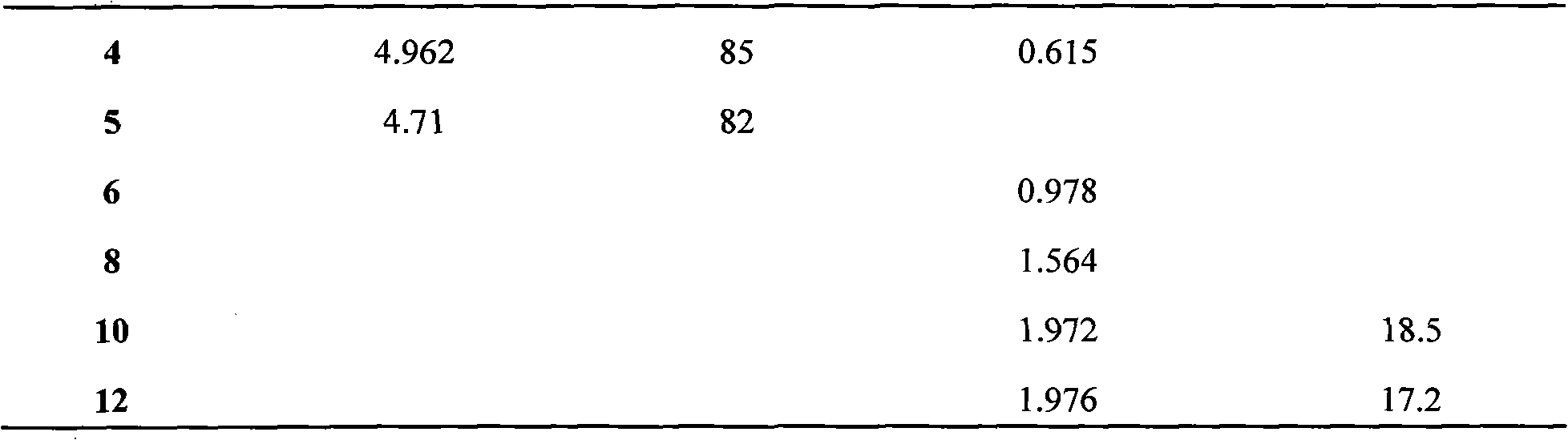

A high-density fermentation and Streptococcus suis technology, which is applied in the field of fermentation medium and its preparation, can solve the problems of not being completely suitable for the growth and metabolism of Streptococcus suis type 2, and achieve the effects of shortening production time, enriching nutrition, and increasing growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Culture medium components and ratio

[0022] Tryptone 28g; Yeast powder 27g;

[0023] Ammonium acetate 0.4g; MgSO 4 ·7H 2 O 0.25g;

[0024] K 2 HPO 4 ·3H 2 O 15g; KH 2 PO 4 1.5g;

[0025] Glucose 2.9g; Bovine serum 5%~15% (V / V);

[0026] Prepared by the following method:

[0027] A. Mix tryptone, yeast powder, ammonium acetate, MgSO 4 ·7H 2 O. After dissolving with distilled water, set the volume to 1000ml, adjust the pH to 7.7, and sterilize under high-pressure steam at 117°C for 20 minutes;

[0028] B. Weigh 100g of glucose, add distilled water to make up to 1000ml, and sterilize under high-pressure steam at 113°C for 20min;

[0029] C. Weigh 22.8g of dipotassium hydrogen phosphate trihydrate, add distilled water to make the volume to 100ml, and prepare dipotassium hydrogen phosphate solution. Weigh 13.6g of anhydrous potassium dihydrogen phosphate and add distilled water to make up to 100ml to make a potassium dihydrogen phosphate solution; take 84ml o...

Embodiment 2

[0033] Culture medium components and ratio

[0034] Tryptone 35g; Yeast powder 35g;

[0035] Ammonium acetate 0.5g; MgSO 4 ·7H 2 O 0.5g;

[0036] K 2 HPO 4 ·3H 2 O 20g; KH 2 PO 4 5g;

[0037] Glucose 5g; Bovine serum 15% (V / V);

[0038] Prepared by the following method:

[0039] A. Mix tryptone, yeast powder, ammonium acetate, MgSO 4 ·7H 2 O. After dissolving with distilled water, set the volume to 1000ml, adjust the pH of the culture medium to 7.8 before sterilization, and sterilize under high-pressure steam at 121°C for 25 minutes;

[0040] B. Weigh 100g of glucose, add distilled water to make up to 1000ml, and sterilize under high-pressure steam at 115°C for 25min;

[0041] C. Weigh 22.8g of dipotassium hydrogen phosphate trihydrate, add distilled water to 100ml, and prepare dipotassium hydrogen phosphate solution; weigh 13.6g of anhydrous potassium dihydrogen phosphate, add distilled water to 100ml, and prepare dibasic phosphate Potassium hydrogen phosphate so...

Embodiment 3

[0046] Culture medium components and ratio

[0047] Tryptone 15g; Yeast powder 15g;

[0048] Ammonium acetate 0.1g; MgSO 4 ·7H 2 O 0.1g;

[0049] K 2 HPO 4 ·3H 2 O 10g; KH 2 PO 4 1g;

[0050] Glucose 1g; Bovine serum 5% (V / V);

[0051] Prepared by the following method:

[0052] A. Mix tryptone, yeast powder, ammonium acetate, MgSO 4 ·7H 2 O. After dissolving with distilled water, set the volume to 1000ml, adjust the pH to 7.4, and sterilize under high-pressure steam at 115°C for 15 minutes;

[0053] B. Weigh 100g of glucose, add distilled water to make up to 1000ml, and sterilize under high-pressure steam at 110°C for 15min;

[0054] C. Weigh 22.8g of dipotassium hydrogen phosphate trihydrate, add distilled water to make the volume to 100ml, and prepare dipotassium hydrogen phosphate solution. Weigh 13.6g of anhydrous potassium dihydrogen phosphate and add distilled water to make up to 100ml to make potassium dihydrogen phosphate solution; take 84ml of dipotassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com