Laser inner hole quenching device

A quenching device and laser quenching technology, applied in the field of laser quenching, can solve the problems of low quenching processing efficiency, insufficient processing accuracy, and bloated structure of the inner hole of the workpiece, and achieve the effects of reducing drive energy consumption, convenient operation, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

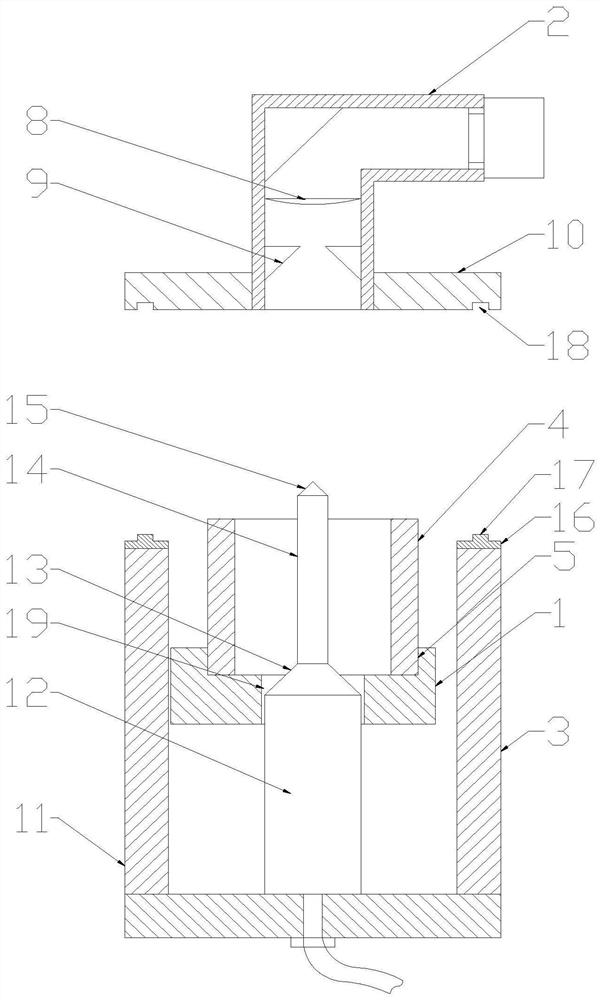

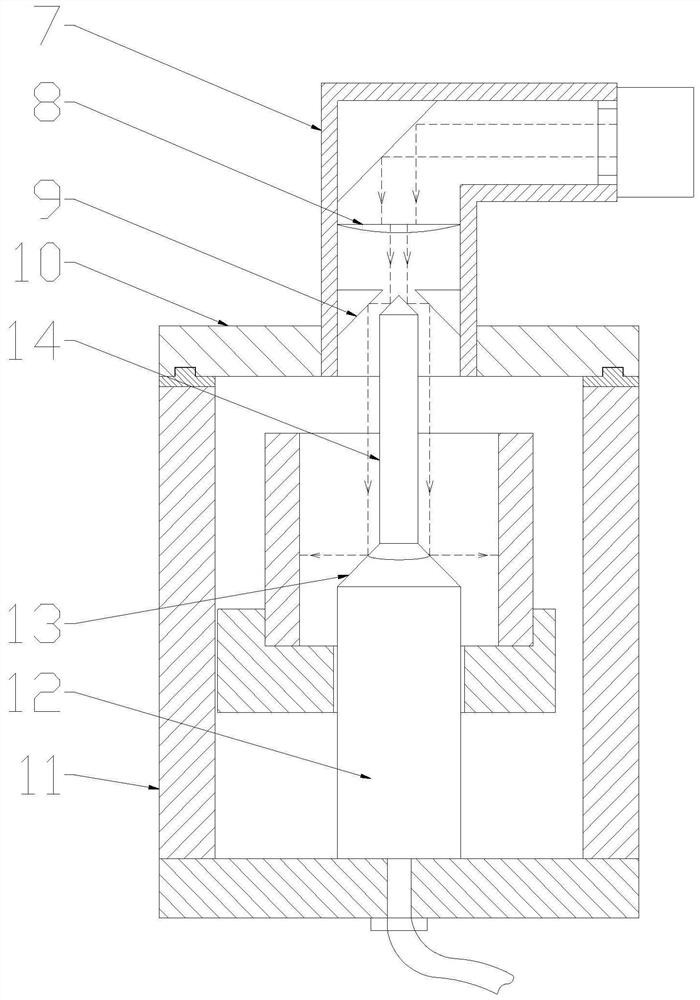

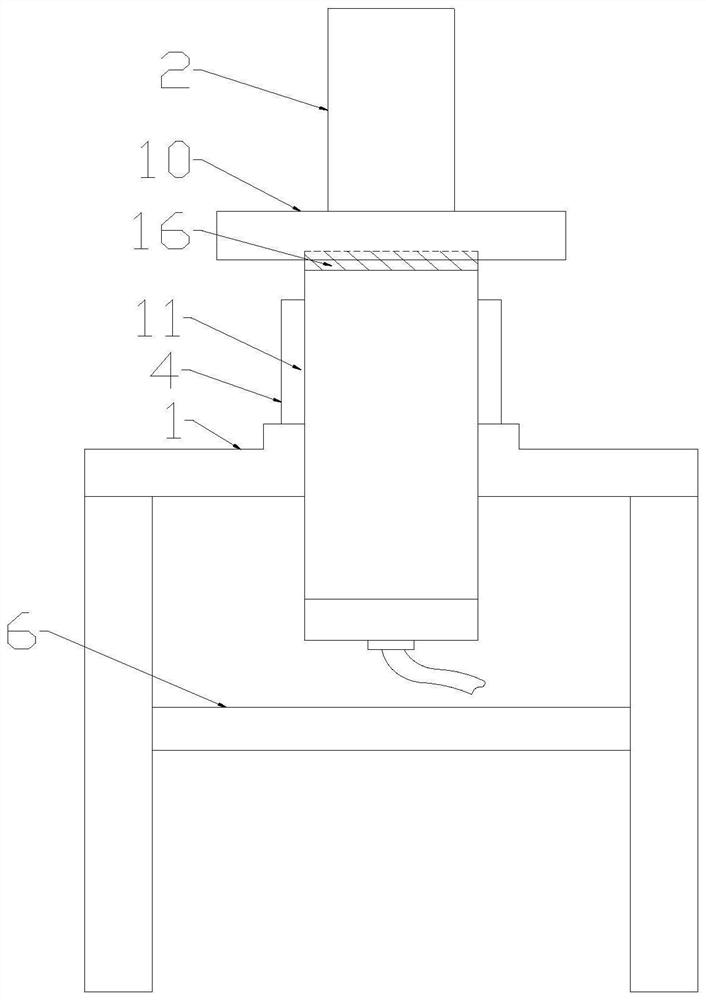

[0028] Such as Figure 1 to Figure 3 As shown, a laser inner hole quenching device includes a workpiece holder 1 , a laser quenching head 2 and a follower seat 3 .

[0029] Please refer to figure 1 and image 3 , the workpiece frame 1 is used to support a metal workpiece with an inner hole, and the upper surface of the workpiece frame 1 is provided with a workpiece positioning groove 5 matching the shape of the workpiece 4 . The bottom of the workpiece holder 1 is provided with a distance from the ground for assembling the follower 3, and the follower 3 can be sent in from the bottom of the workpiece holder 1 and then lifted up to surround the both sides of the workpiece holder. The two legs of the workpiece rack 1 are provided with strip holes, and the strip holes are fastened with horizontal supporting plates 6 by bolts. The installation height of the supporting plates 6 in the strip holes can be adjusted. Before assembling the follower seat 3 , move the supporting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com