Ship lift lifting type double-steel-beam anti-collision system and redundant blocking and preventing method thereof

An anti-collision system and a ship lift technology are applied in the fields of mechanical devices and ship lift engineering, and can solve the problems of not being able to meet the need for blocking a ship with a bulbous bow, the ship colliding with the door of the cabin, and the impact stroke being large, etc. The effect of less space, reduced collision force, and large safety redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

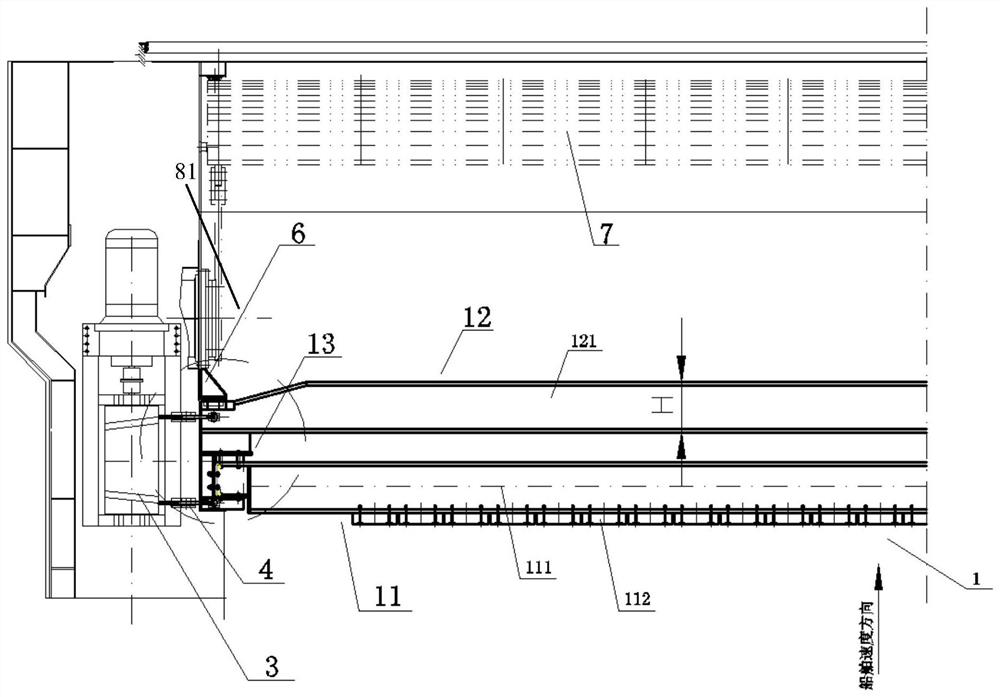

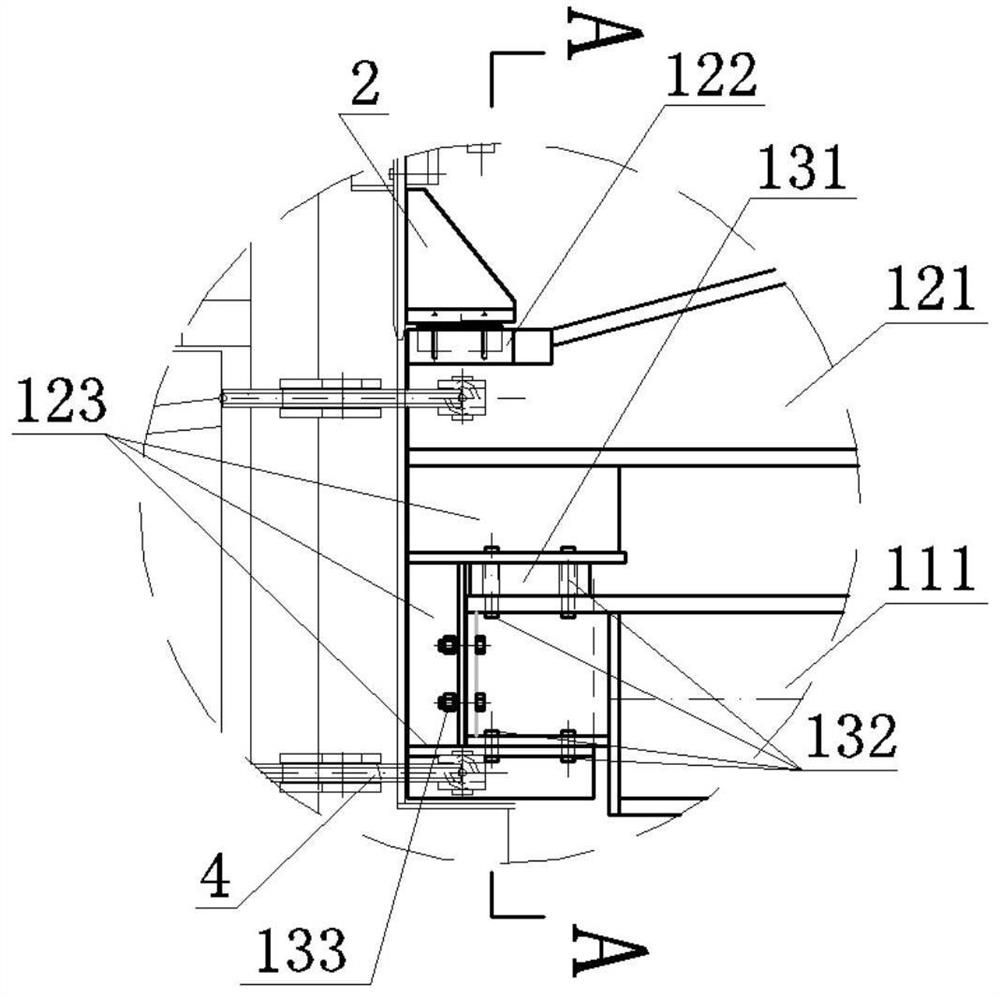

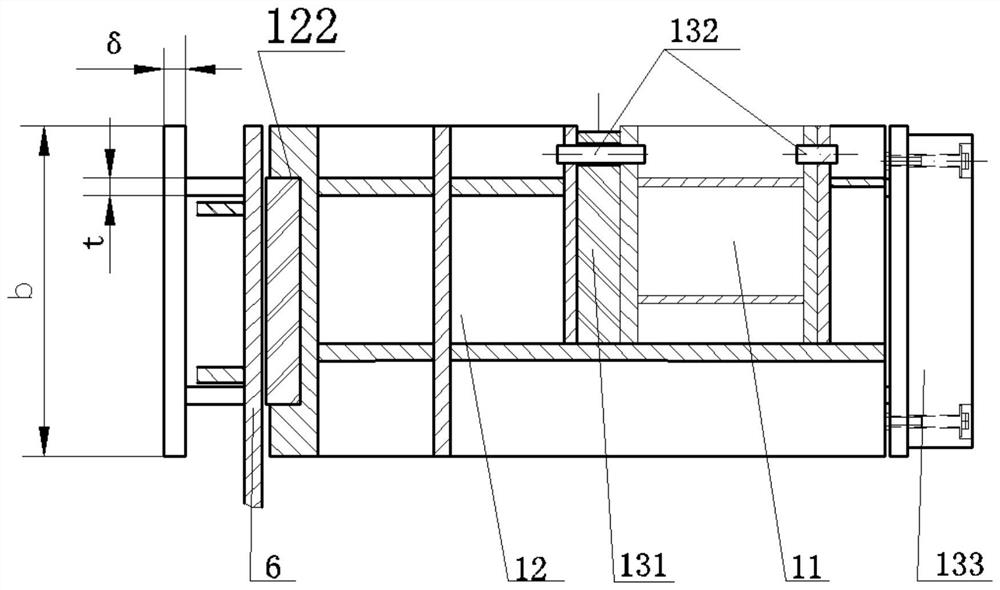

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] The invention is applicable to the protection of the ship compartment door by the vertical ship lift of the water conservancy project under the condition of the ship stall accident, so as to prevent the ship compartment door from being damaged by the impact of the ship in the case of the ship stall accident and causing a large number of water leakage accidents in the ship compartment. The system mainly uses two-stage plastic steel girders to block the stalled ship to form redundant safety protection for the cabin door, thereby ensuring the safety of the cabin door.

[0035] Please refer to Figure 1 ~ Figure 2, a lift type double steel girder anti-collision system for a ship lift, comprising a double barrier steel girder assembly 1, a supporting member assembly 2, a lifting drive device 3, a reversing device 4, a lifting connection assembly 5 and a supporting structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com