Inflated membrane structure with improved structure, heat insulation system and heat insulation construction method

A construction method and technology of inflatable membranes, applied in special structures, thermal insulation, building components, etc., can solve problems such as poor thermal insulation effect, continuity, and cold bridges, achieve excellent thermal insulation capabilities, transform building appearance, Reasonable effect of structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

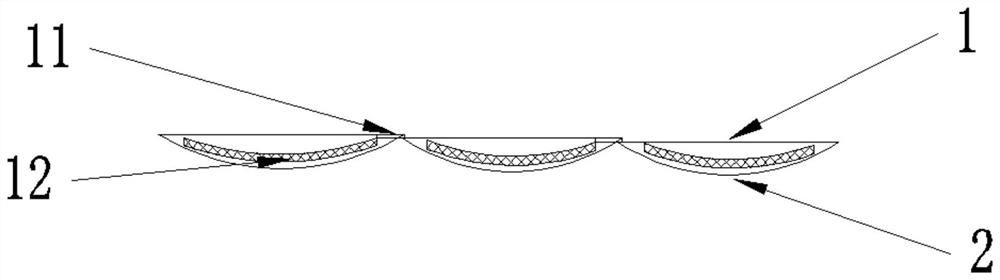

Embodiment 1

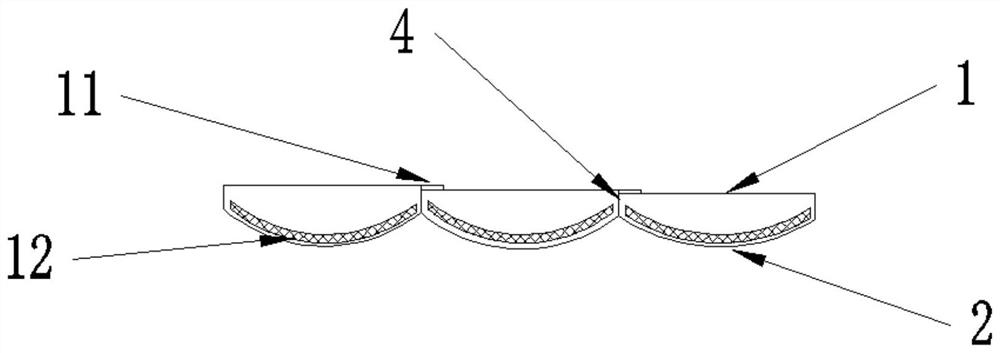

[0054] Based on the prior art, one of the improved structures is: at each outer welding seam 11 , correspondingly increase the connecting film strip 4 so that there is a sufficient distance between the outer film 1 and the inner film 2 . With such an inflatable membrane structure, the point where the outer membrane 1 and the inner membrane 2 are welded together is eliminated, the outer membrane 1 and the inner membrane 2 are separated, and the gap between the outer membrane 1 and the inner membrane 2 is widened. The distance between them makes the air interlayer between the outer film 1 and the inner film 2 thicker, so that the thermal insulation structure can be installed, and the thermal insulation performance of the part without thermal insulation filling is also improved. However, due to installation problems, the insulation structure is still composed of multiple sections of outer insulation layer 12 respectively arranged between two adjacent outer welds 11, and it is stil...

Embodiment 2

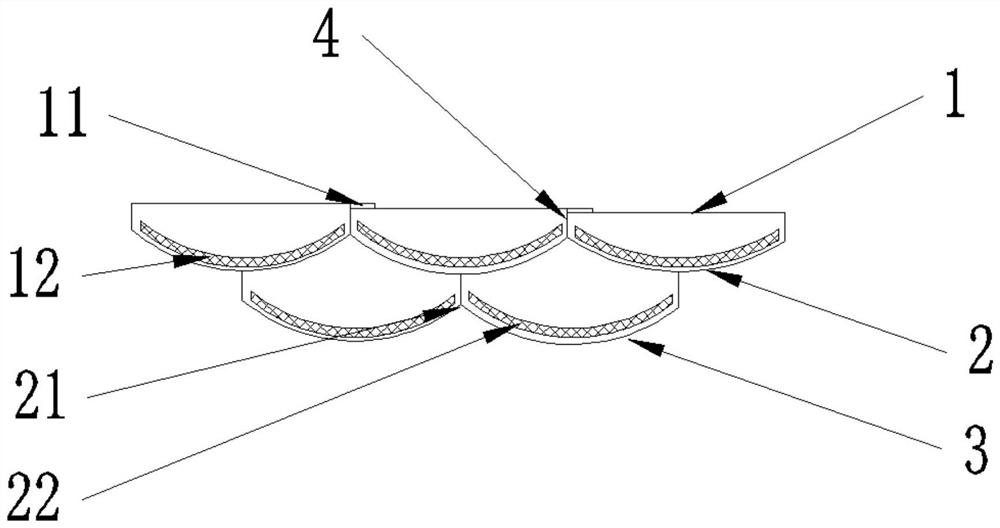

[0059] Such as image 3 As mentioned above, on the basis of Example 1, this embodiment adds a layer of lining film 3 and the corresponding heat preservation structure to form an overall structure of three layers of film and two layers of heat preservation. The structure is reasonable and the heat preservation effect is good.

[0060] Specifically: the outer layer film 1, the inner layer film 2 and the inner lining film 3 are sequentially stacked from outside to inside; The welding seam 11 is connected, and the heat preservation structure between the outer layer film 1 and the inner layer film 2 is composed of a plurality of outer heat preservation layers 12 respectively arranged between two adjacent outer weld seams 11, and the inner layer film 2 It is connected with the inner lining film 3 through multiple intervals of inner welds 21, and the thermal insulation structure between the inner layer film 2 and the inner lining film 3 is respectively arranged between two adjacent i...

Embodiment 3

[0071] Such as Figure 4 As shown, based on the overall structure of three layers of film, two layers of heat preservation and the requirement that each heat preservation structure overlap each other in the stacking direction of each film to avoid cold bridges, there are also the following feasible technical solutions: the outer film 1 is a layer continuous film, the heat preservation structure between the outer film 1 and the inner film 2 is a continuous outer heat preservation coating 13, and the inner film 2 and the inner lining film 3 are internally welded at multiple intervals. The heat preservation structure between the inner layer film 2 and the inner liner film 3 is composed of a plurality of inner heat preservation layers 22 respectively arranged between two adjacent inner weld seams 21 .

[0072] In embodiment 3, the outer layer membrane 1 is not arranged to be multi-section welded by welding seams, but adopts a continuous membrane structure, and the thermal insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com