Prefabricated external wall component for passive house, connection structure and construction method

A passive house and exterior wall technology, applied to building components, walls, building structures, etc., can solve the problems of no wall reinforcement connection structure, improvement of assembly construction efficiency, etc., to improve waterproof effect, increase concrete area, and improve connection The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

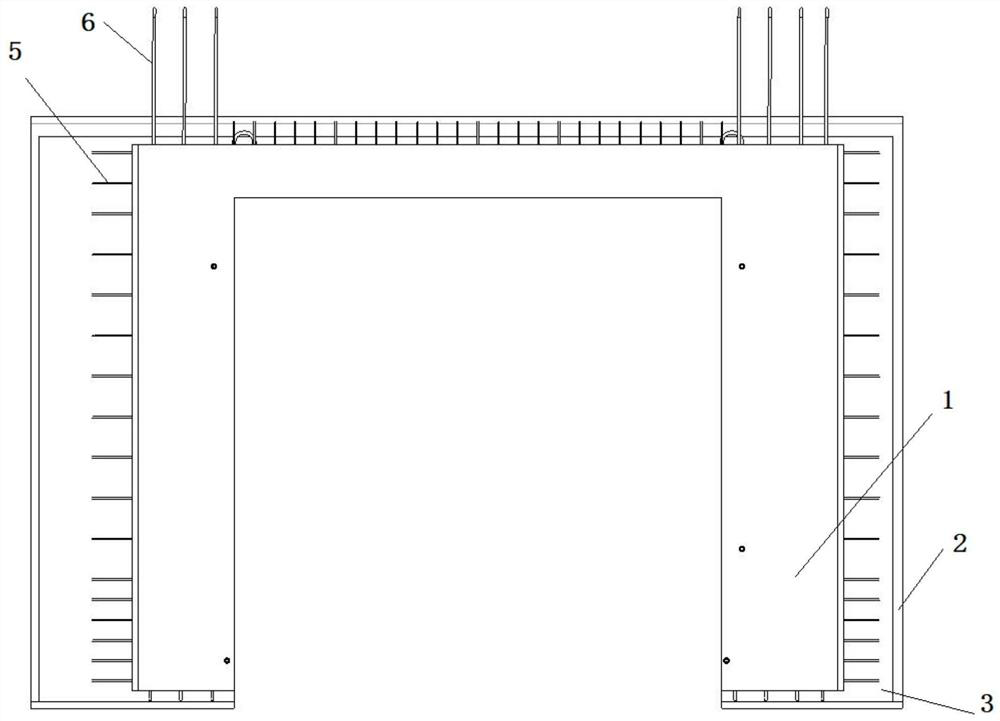

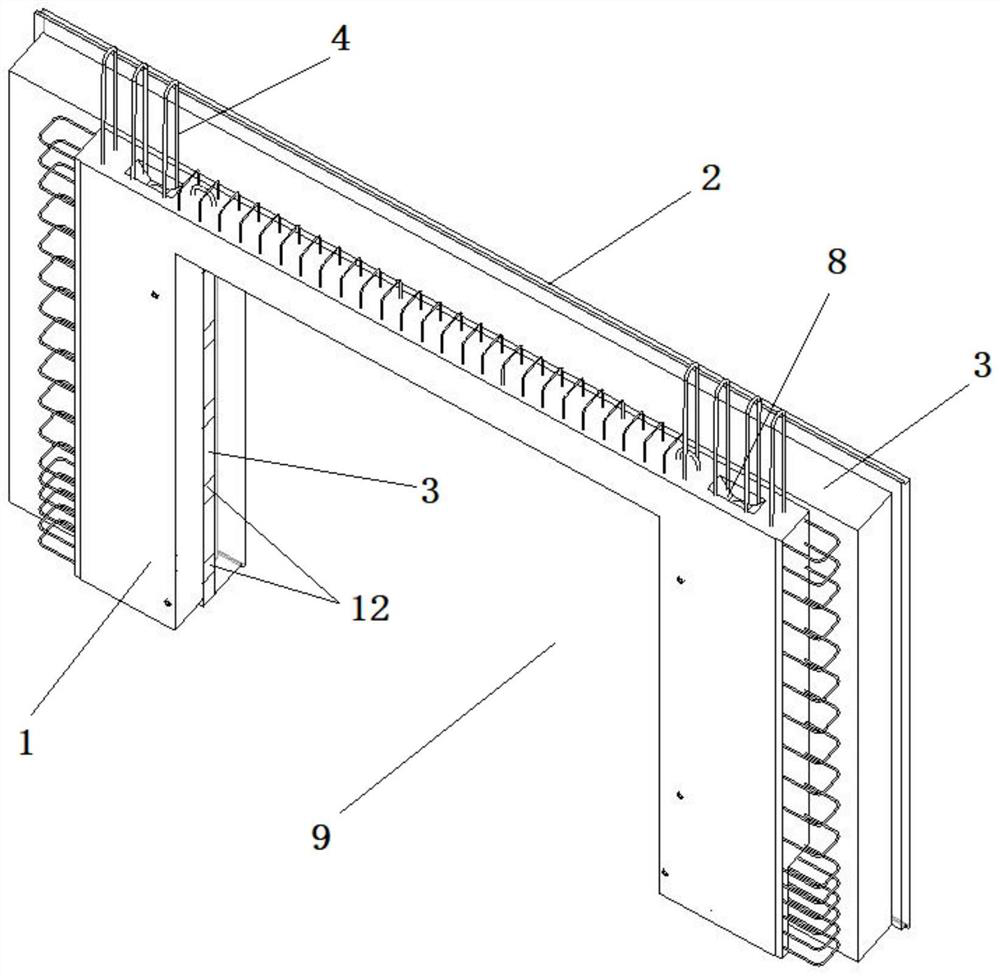

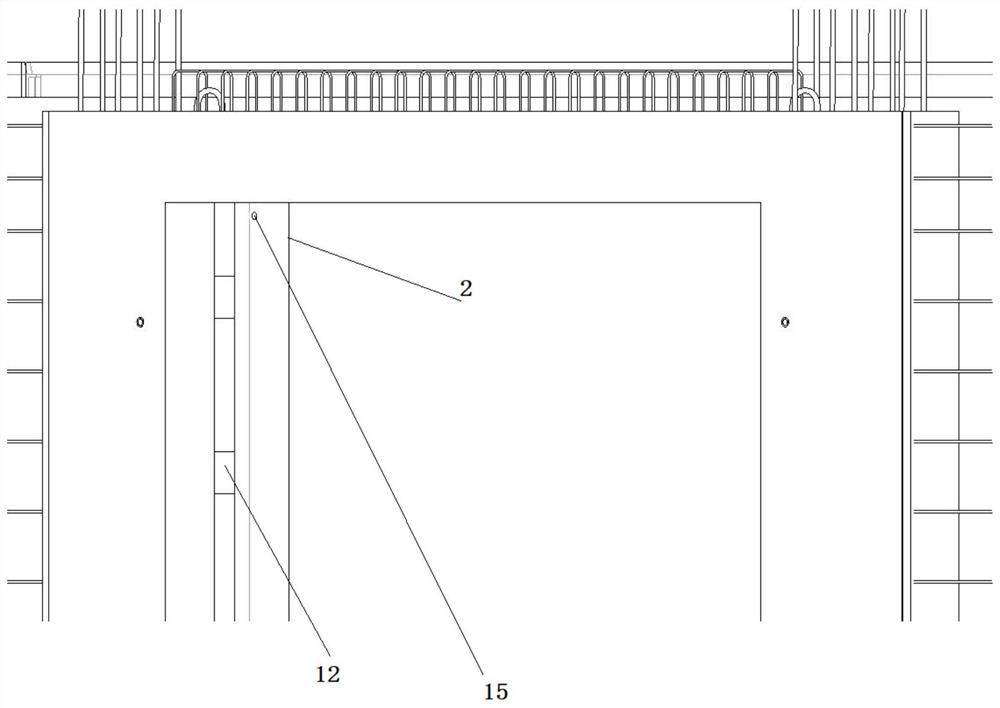

[0078] combine Figure 1-18 , in the present embodiment, a part of the outer leaf wall 2 protrudes toward the direction of the inner leaf wall 1, forming an anti-edge 11, that is, a part of the outer leaf wall 2 is thicker than its surroundings. Correspondingly, the insulation layer 3 between the anti-edge 11 and the inner leaf wall 1 is thinner relative to the insulation layer 3 of the rest.

[0079] The hole 9 that is used to install door and window is from outer leaf wall 2, passes through inner leaf wall 1 through anti-edge 11, thermal insulation layer 3. A fixing component is provided at the insulation layer 3 between the anti-edge 11 and the inner leaf wall 1 for installing doors and windows. In some embodiments, the fixing part can be wooden bricks 12 embedded in the thermal insulation layer 3, the number of wooden bricks 12 is multiple, arranged at intervals along the thermal insulation board, the surface of the wooden bricks 12 is exposed on the inner edge of the hol...

Embodiment 2

[0090] The difference between this embodiment and embodiment 1 is:

[0091] combine Figure 19-27 , a part of the inner leaf wall 1 and a part of the outer leaf wall 2 protrude toward each other, forming two anti-edges 11, and between the two anti-edges 11 is the insulation layer 3, which is thinner than other parts, correspondingly Ground, the inner leaf wall 1 and the outer leaf wall 2 are thicker at the part along the anti-edge 11 than other parts. The fixing part that is used to install door and window is arranged between two anti-edges 11, and correspondingly, door and window is also installed in the part between two anti-edges 11. That is, the door and window are located in the middle part between the outer leaf wall 2 and the inner leaf wall 1 . Fixing part can adopt wooden brick 12 or subframe among the embodiment 1.

[0092]On the other hand, the longitudinal steel bars 4 are exposed in the cast-in-place cavity 6, specifically, a number of exposed rib grooves 13 ar...

Embodiment 3

[0094] The difference between this embodiment and embodiment 1 is:

[0095] combine Figure 28-37 , a part of the inner leaf wall 1 protrudes toward the outer leaf wall 2 to form an anti-edge 11, that is, a part of the inner leaf wall 1 is thicker than its surroundings. Correspondingly, the insulation layer 3 between the anti-edge 11 and the outer leaf wall 2 will be thinner relative to the insulation layer 3 of the rest.

[0096] The hole 9 that is used to install door and window is from inner leaf wall 1, passes through anti-edge 11, insulation layer 3, and runs through outer leaf wall 2. A fixing part is provided at the insulation board between the anti-edge 11 and the outer leaf wall 2 for installing doors and windows. In some embodiments, the fixing part can be wooden bricks 12 embedded in the thermal insulation layer 3, the number of wooden bricks 12 is multiple, arranged at intervals along the thermal insulation board, the surface of the wooden bricks 12 is exposed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com