600MW unit circulating water energy-saving optimization operation prompting method

A technology that optimizes operation and circulates water. It is used in mechanical equipment, machines/engines, and liquid variable-capacity machinery. It can solve problems such as waste of adjustment resources, potential safety hazards, and waste of energy. It can improve adjustment speed, improve accuracy, The effect of eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

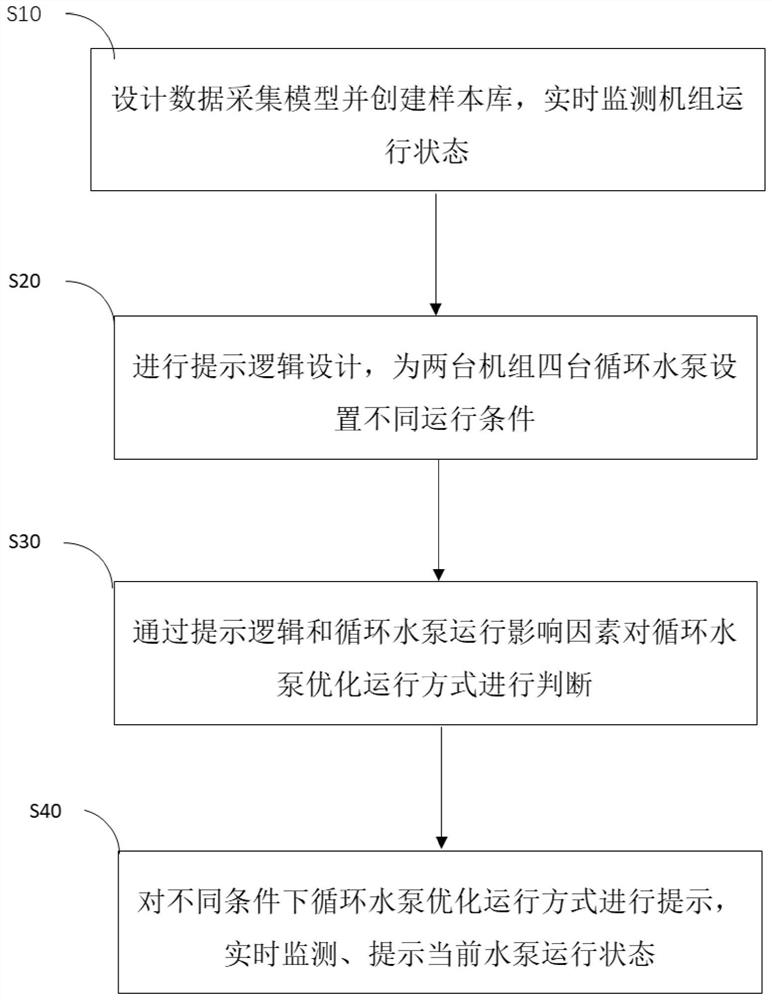

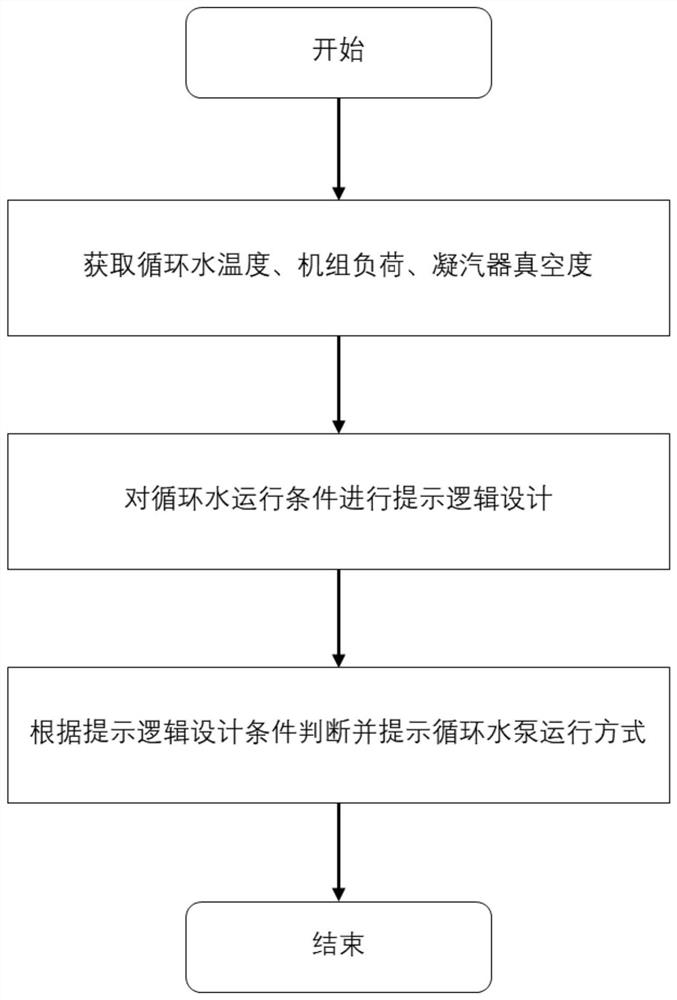

[0080] see image 3 , in the embodiment of the present invention, a 600MW unit circulating water energy-saving optimization operation prompting method is provided with two double-speed motors, which are #1 unit B circulating water pump motor and #2 unit B circulating water pump motor.

[0081] Step S10 collects the circulating water temperature, unit load, and condenser vacuum data of units #1 and 2 in real time, and transmits them to the background sample library;

[0082] Step S20 uses the influencing factors to carry out prompt logic design on the operating conditions of the #1 and 2 machine B circulating water pumps;

[0083] Step S30 judges the optimal operation mode of the circulating water pump through the prompt logic and the influencing factors of the circulating water pump operation. The influencing factors include circulating water temperature, unit load, and condenser vacuum. By comparing the current influencing factors of the circulating water pump with the standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com