Method and system for predicting service life of clutch with displacement sensor booster

A technology of displacement sensor and life prediction, which is applied in the testing of machine/structural parts, testing of mechanical parts, instruments, etc., and achieves the effects of wide application prospects, significant progress, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

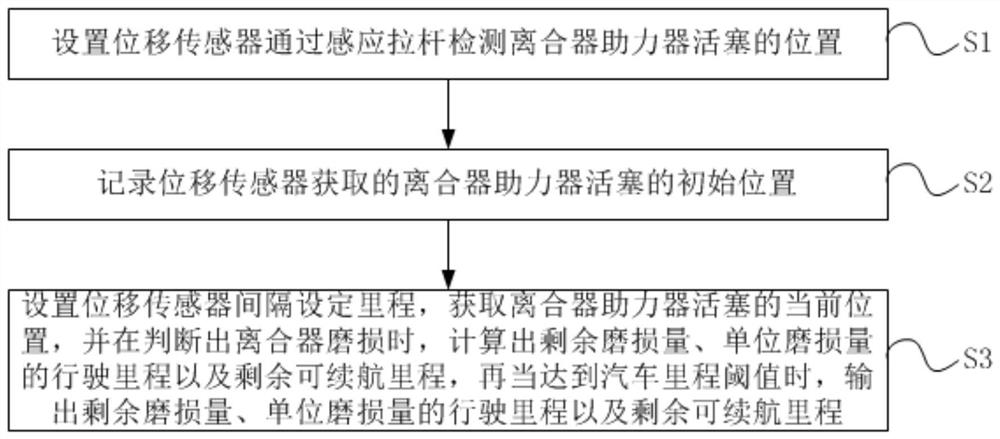

[0061] Such as figure 1 with figure 2 As shown, the present invention provides a clutch life prediction method with a displacement sensor booster, comprising the following steps:

[0062] S1. Set the displacement sensor to detect the position of the clutch booster piston through the induction pull rod;

[0063] S2. Record the initial position of the clutch booster piston obtained by the displacement sensor;

[0064] S3. Set the displacement sensor interval to set the mileage, obtain the current position of the clutch booster piston, and when the clutch wear is judged, calculate the remaining wear, the mileage per unit wear and the remaining cruising range, and then when the mileage of the car is reached When the threshold is reached, the remaining wear amount, the mileage per unit wear amount and the remaining cruising range are output.

Embodiment 2

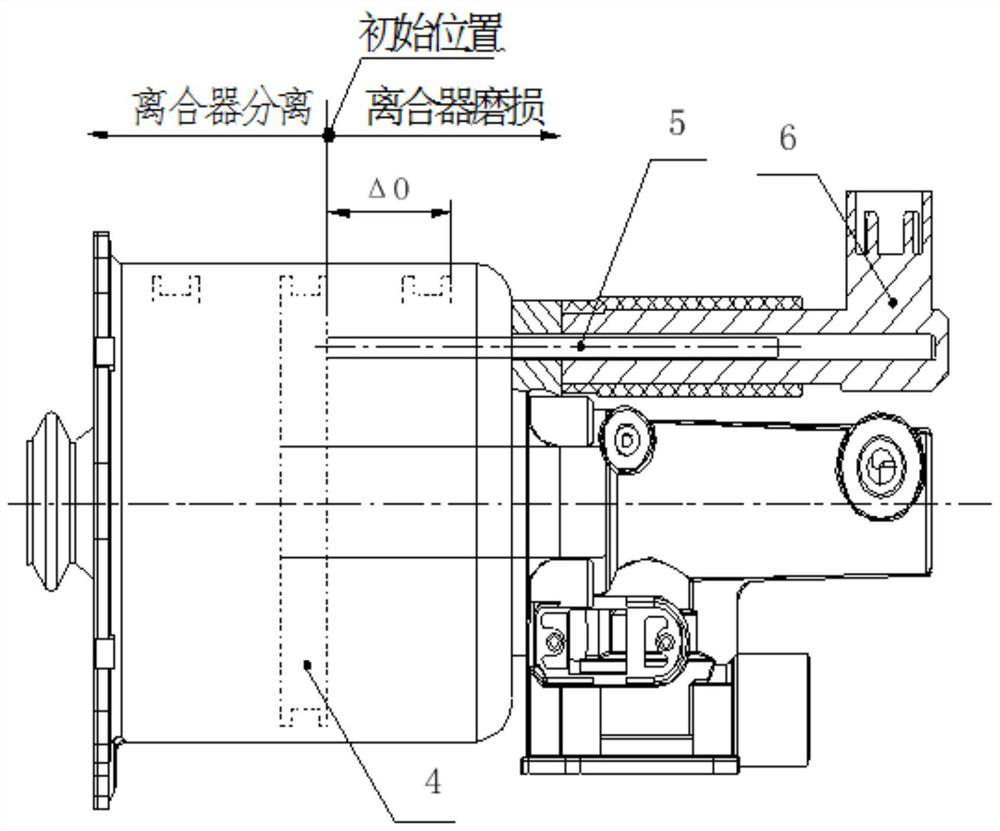

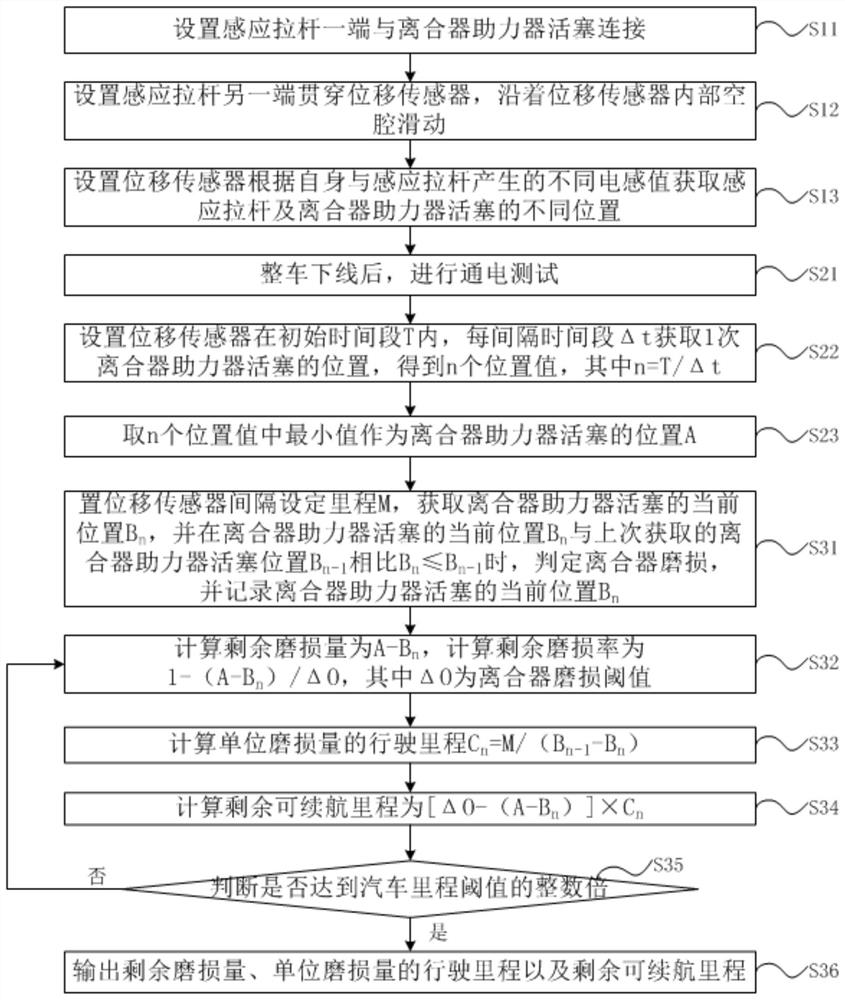

[0066] Such as figure 2 with image 3 As shown, the present invention provides a clutch life prediction method with a displacement sensor booster, comprising the following steps:

[0067] S1. Set the displacement sensor to detect the position of the clutch booster piston through the induction rod; the specific steps are as follows:

[0068] S11. Set one end of the induction rod to connect with the clutch booster piston;

[0069] S12. Set the other end of the induction rod to penetrate the displacement sensor and slide along the internal cavity of the displacement sensor;

[0070] S13. Set the displacement sensor to obtain different positions of the sensing rod and the clutch booster piston according to the different inductance values generated by itself and the sensing rod;

[0071] S2. Record the initial position of the clutch booster piston obtained by the displacement sensor; the specific steps are as follows:

[0072] S21. After the vehicle is off the assembly line,...

Embodiment 3

[0104] Such as Figure 4 As shown, the present invention provides a clutch life prediction system with a displacement sensor booster, comprising:

[0105] The clutch booster piston position detection module 1 is used to set the displacement sensor to detect the position of the clutch booster piston through the induction pull rod; the clutch booster piston position detection module 1 includes:

[0106] Induction rod piston connection unit 1.1, used to connect one end of the induction rod to the clutch booster piston;

[0107] The connection unit 1.2 of the induction rod displacement sensor is used to set the other end of the induction rod through the displacement sensor and slide along the internal cavity of the displacement sensor;

[0108]The displacement sensor detection unit 1.3 is used to set the displacement sensor to obtain different positions of the induction rod and the clutch booster piston according to the different inductance values generated by itself and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com