Non-metallic material plane heating device

A non-metallic material and planar heating technology, which is applied in the direction of electric heating devices, heating element materials, heating elements, etc., can solve the problems of easy generation of open flames, low safety performance, and short life, so as to improve heat conversion efficiency and simplify the production process , The effect of increasing the temperature of the air outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

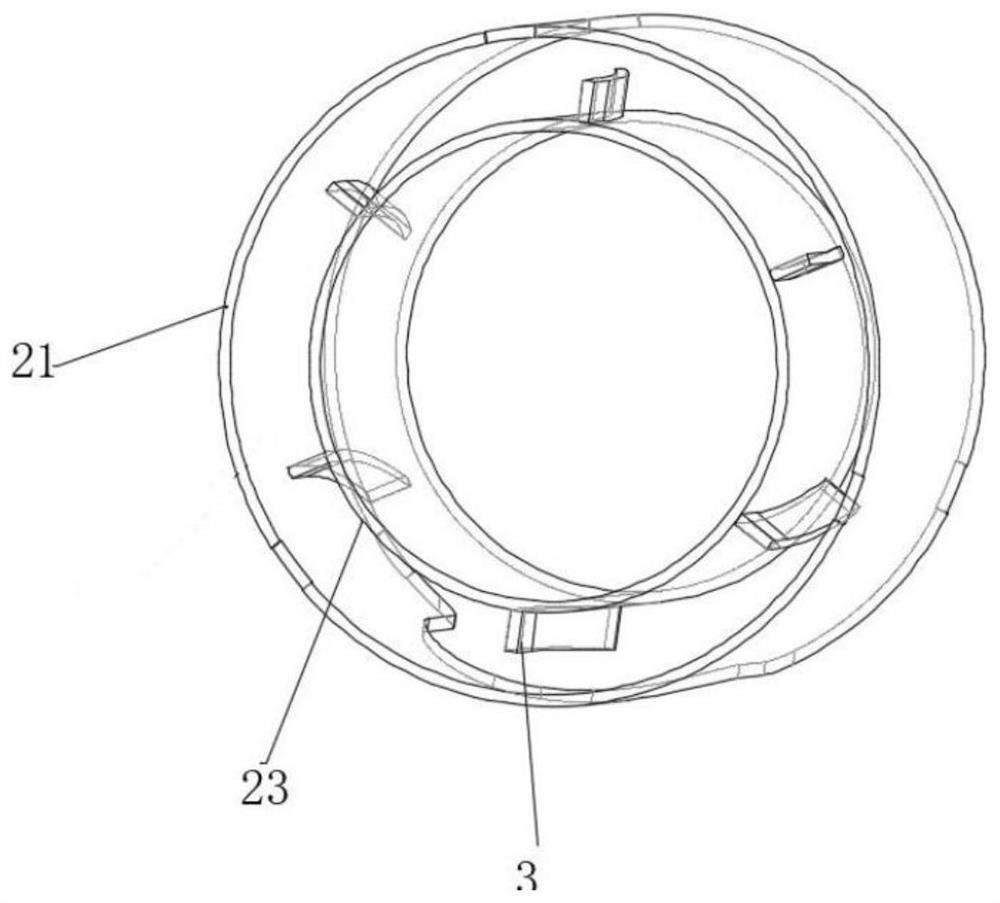

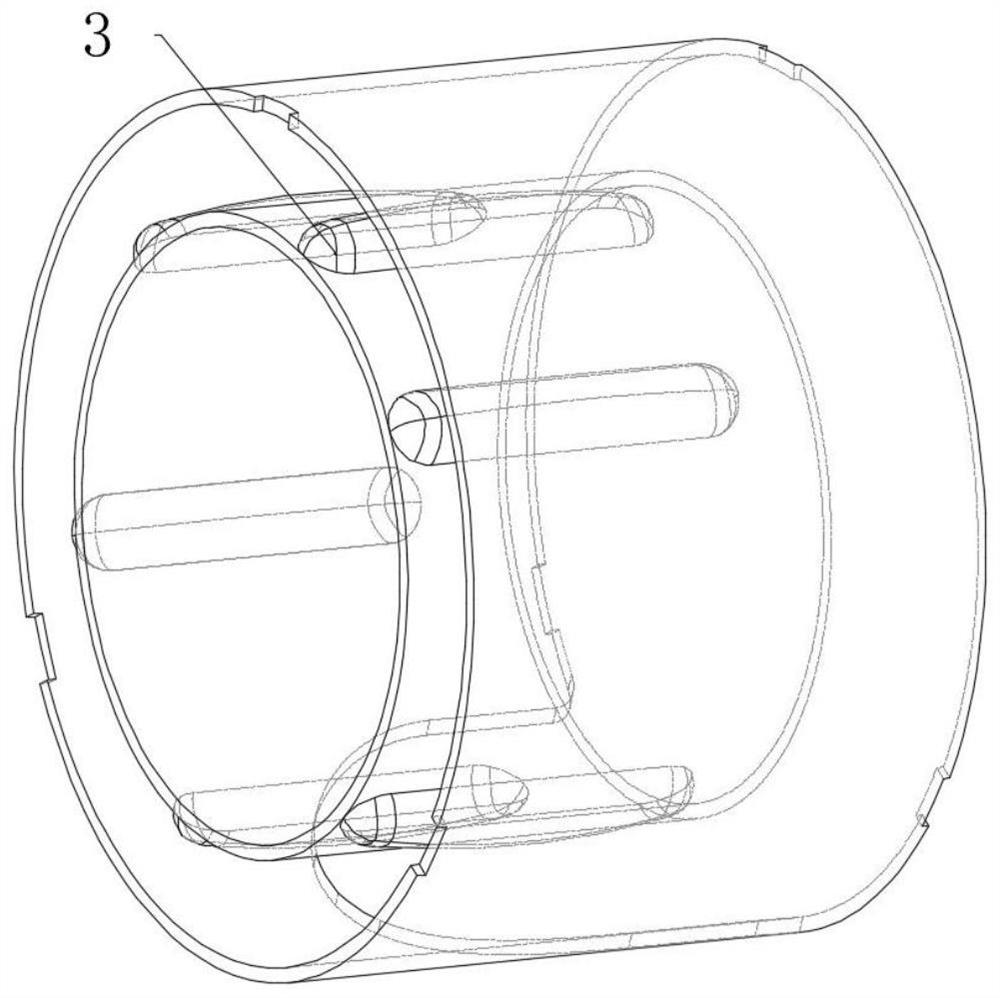

[0028] refer to Figure 1 to Figure 24 As shown, the present invention discloses a non-metal material planar heating device, comprising:

[0029] The heating element assembly 21 and the air duct structure assembly 23 . The heating element assembly 21 is fixed on the air duct structure assembly 23 .

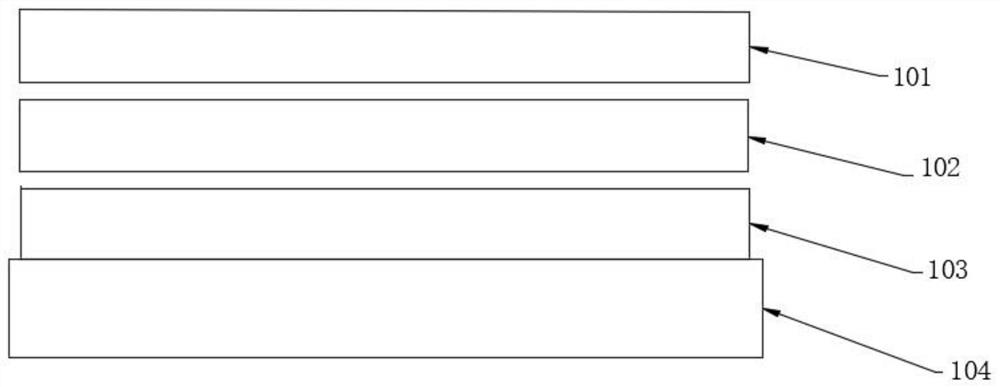

[0030] The above-mentioned heating element components are composed of non-metallic conductive heating materials, high-temperature adhesives and high-temperature-resistant insulating materials, which are mixed and formulated to obtain required resistance values.

[0031] The above-mentioned non-metallic conductive heating material includes carbon materials such as graphene and PI carbon fiber, and its heating temperature can exceed 200°C.

[0032] The above-mentioned air duct structure component has two conductive silver electrodes insulated from each other, and the heating element component is connected with the conductive silver electrodes of the air duct structure component. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fever temperature | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com