A hot air insecticide device for grain places

An insecticidal device and hot air technology, which is applied in the device, application, animal husbandry, etc. of catching or killing insects, can solve the problems of local temperature rise not meeting the requirements, incomplete insecticidal treatment, etc. The effect of insecticidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

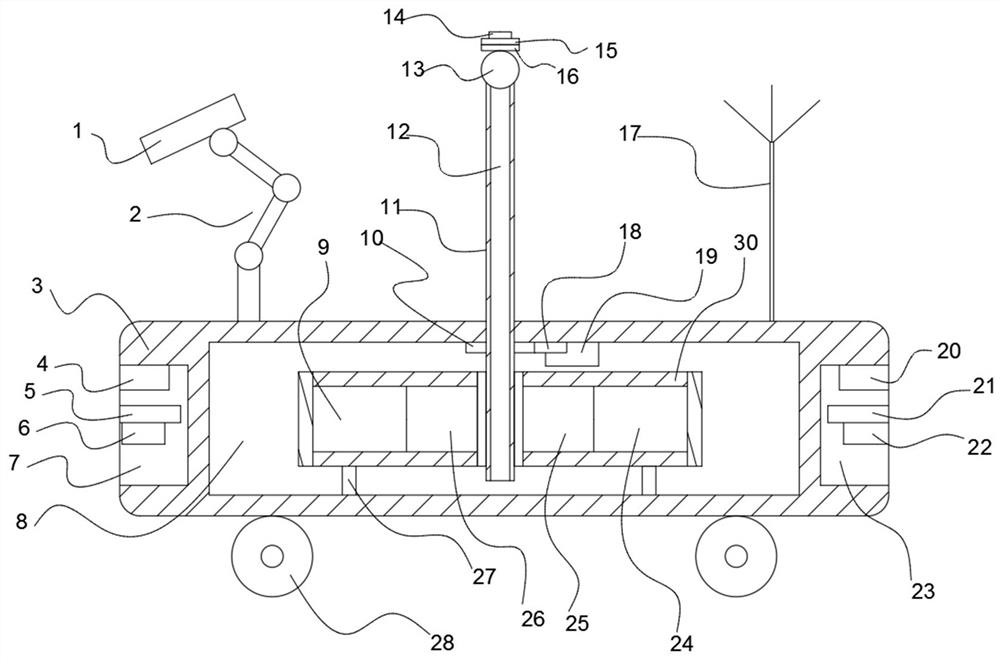

[0021] Examples of the present invention are figure 1 Shown: comprise the traveling vehicle that has traveling mechanism at the bottom, and traveling mechanism comprises four traveling wheels 28, and the hot-air insecticidal device for food places also includes the hot air blower 1 that links to each other with traveling vehicle through mechanical arm 2, and the traveling vehicle is provided with vertical arrangement The installation rod 11, the installation rod guides and moves along the up and down direction and is assembled on the trolley. In the present invention, the trolley includes a shell made of heat-insulating material, such as glass fiber, asbestos, etc., and the lifting rod driving mechanism includes a drive motor 19 fixed on the inner wall of the shell, and the power output end of the drive motor 19 is connected to a Screw nut 18, the outer circumference of the lifting rod 11 is provided with a screw thread that cooperates with the screw nut 18, and the lifting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com