Accurate mold taking method and device for multi-tooth implantation

An accurate and tooth-positioned technology, applied in the field of accurate impression taking of multi-dentate implants, can solve the problems affecting the accuracy of impression taking and the time-consuming time of taking impressions, and achieve the effect of increasing the scope of popularization, improving speed and efficiency, and accurate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

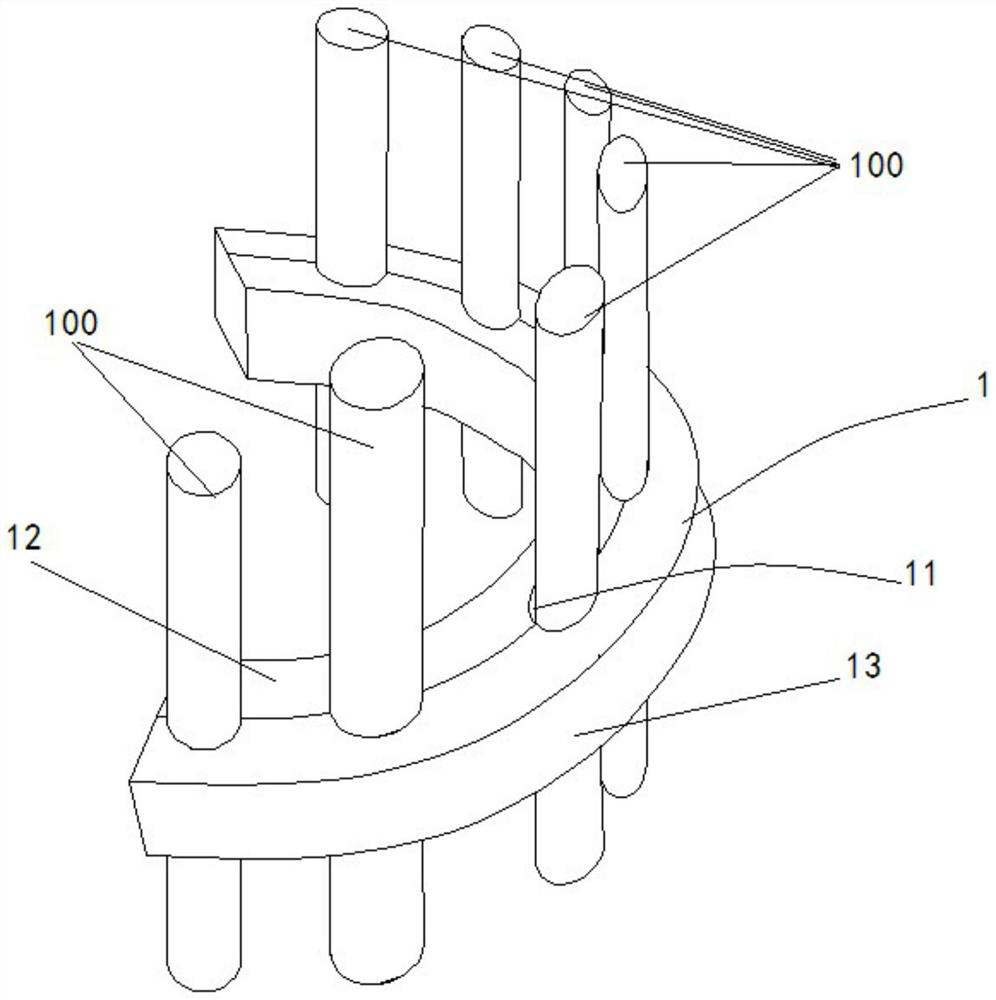

[0048] see Figure 1~5 , a method for accurately taking impressions for multi-dental implants provided by the present invention, comprising the following steps:

[0049] 1) Take a number of implant impression bars 100, the number of implant impression bars 100 corresponds to the number of teeth to be implanted, and install one end of the implant impression bars 100 on the implant (not shown) in the oral cavity through screws (not shown). icon);

[0050] 2) Using an intraoral scanner to scan and obtain the three-dimensional point cloud data of each implant impression post 100 and the three-dimensional point cloud data of oral tissues around the implant impression post 100;

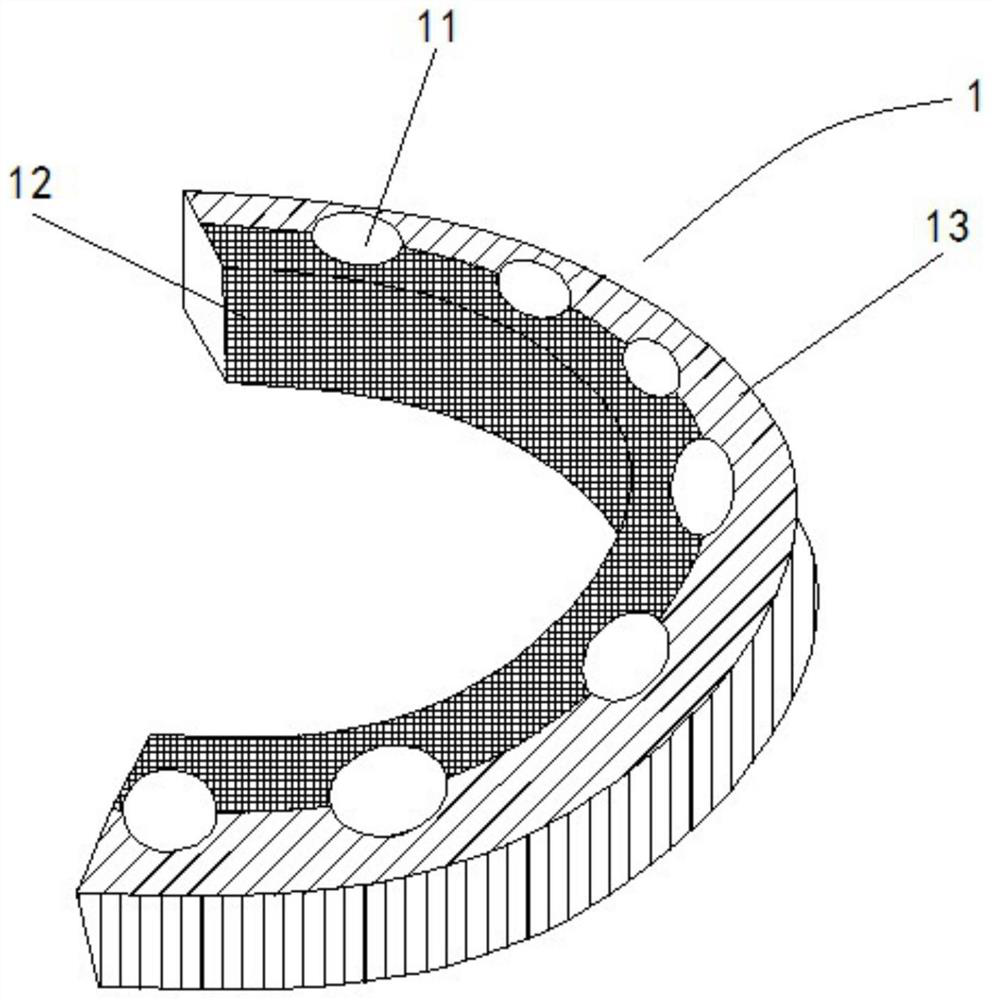

[0051] 3) Edit and model the 3D point cloud data obtained in step 2) by using the software supporting the intraoral scanner to obtain an arc-shaped 3D fixed block model corresponding to the shape of the dental arch in the oral cavity, and the 3D fixed block model Several fixing holes 11 are arranged at in...

Embodiment 2

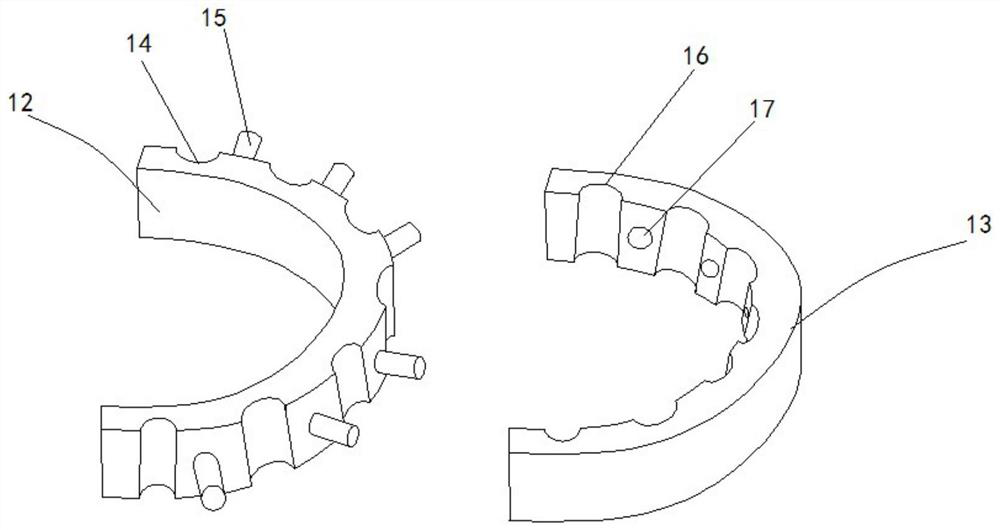

[0088] The end face of the internal fixed impression facing the three-dimensional tray model is provided with several guide bolts 18 at intervals along the circumference of the internal fixed impression; and / or, the end face of the external fixed impression facing the three-dimensional tray model is along the circumference of the internal fixed impression Some guide bolts 18 are arranged at intervals; the inner bottom surface of the bracket 22 of the three-dimensional tray model is convexly provided with guide bolts 24 matched with the guide bolts; the three-dimensional tray model is coated on the three-dimensional fixed block model, and the guide The plug body 24 is inserted into the guide bolt channel 18 to form the guidance and positioning between the three-dimensional tray model and the three-dimensional fixed block model.

[0089] The cooperating design of the guide bolt channel 18 and the guide bolt body 24 can accurately realize the precise docking of the tray 2 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com