Binary pneumatic three-jaw manipulator of industrial robot

A technology of industrial robots and manipulators, applied in the field of robots, can solve the problems of time-consuming and laborious, single function of the manipulator, and increase the failure rate of equipment, etc., and achieve the effect of convenient control, reasonable structure and meeting the needs of flexible production systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

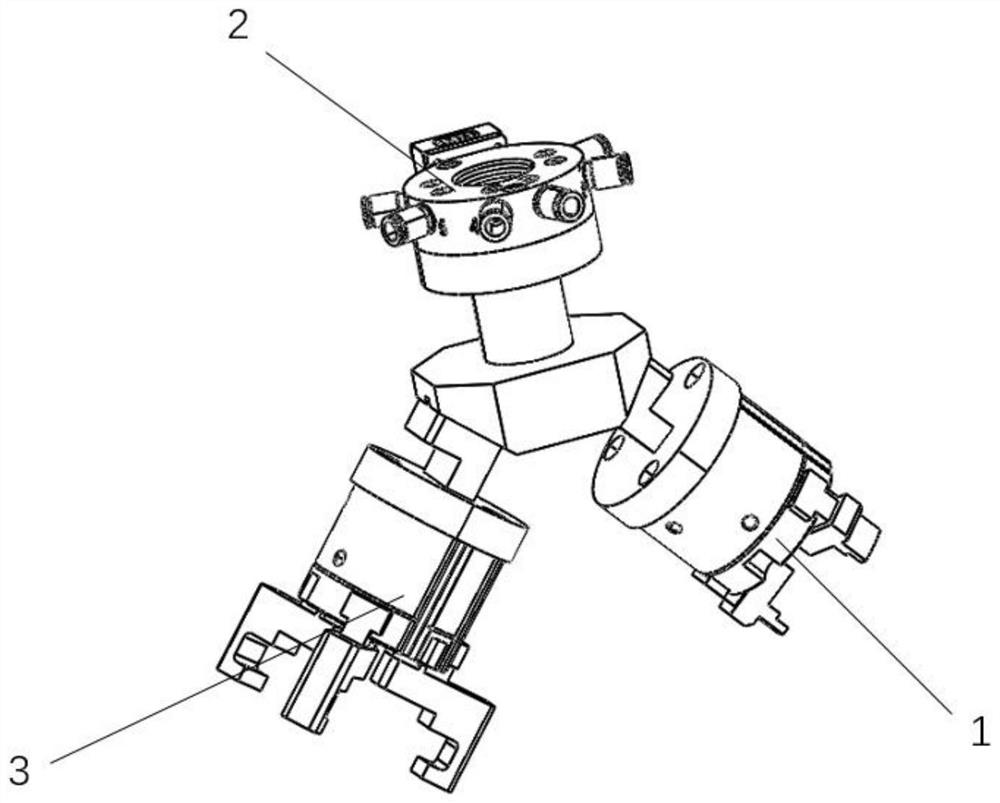

[0017] The invention provides a two-part pneumatic three-claw manipulator for an industrial robot, which is characterized in that it includes a quick-change device 2, an inner card-type manipulator 1, and an outer-card-type manipulator 3. The left and right sides of the bottom of the quick-change device 2 are respectively connected with outer card-type The manipulator 3, the inner card manipulator 1; the quick change device 2 is connected to the end of the rotary robot; the inner card manipulator 1 and the rotary robot form an included angle of 30° along the Z axis, and the outer card manipulator 3 and the rotary robot form an angle of 30° along the Z axis. The axis forms an included angle of -30°;

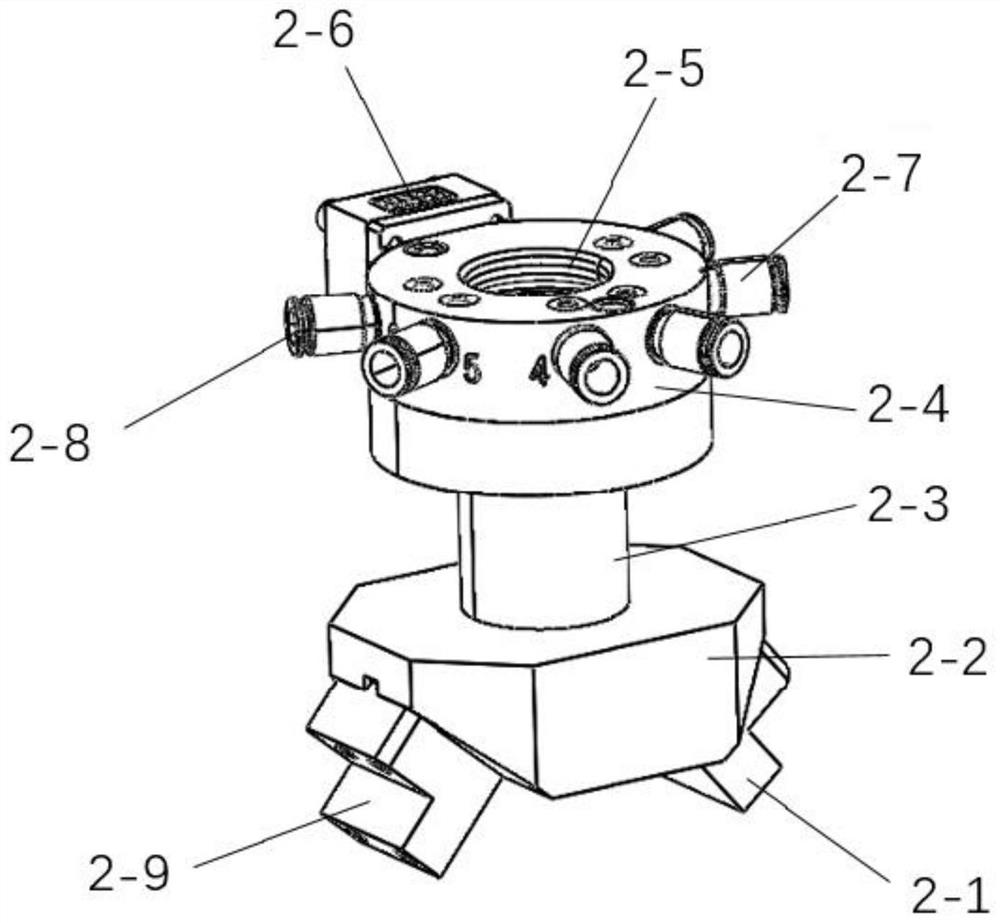

[0018] The quick-change device 2 includes a disc 2-4, a disc cylinder 2-3, a quick-change interface 2-5, an air pipe A2-7, an air pipe B2-8, a magnetic alignment device 2-6, and a bottom block 2- 2. Connecting block A2-9, connecting block B2-1, the bottom end of the disk 2-4 is co...

Embodiment 2

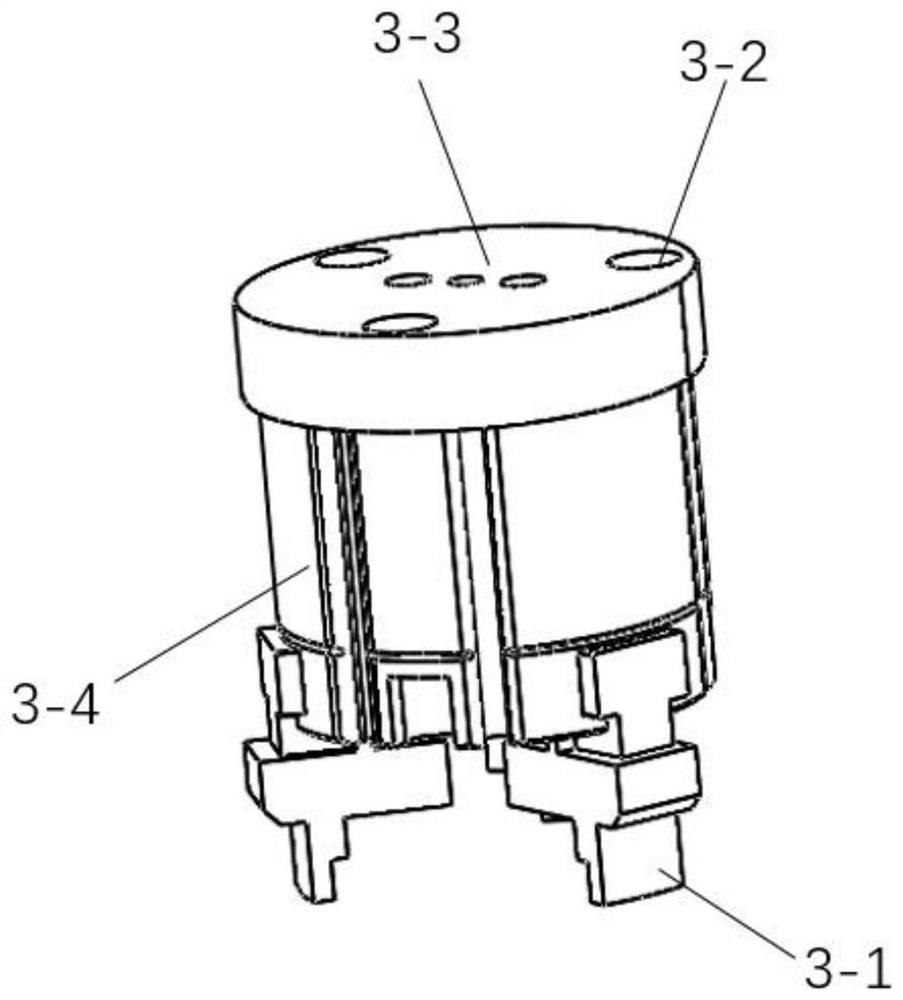

[0025] When using the present invention, the quick-change interface 2-5 of the quick-change device 2 is connected to the rotary robot, and the magnetic alignment device 2-6 enables the quick-change device 2 to be aligned and connected to the rotary robot. Control the air cylinder A4-4 to work by turning on and off the air circuit of the hose connected at the air pipe A2-7, and then make the external card type pneumatic gripper 4-1 work, and control the air cylinder B3 by controlling the air circuit of the hose connected at the air pipe A2-7 -4 works, and then makes the inner card type pneumatic gripper 3-1 work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com