Apparatus for measuring elevations of the surface of a rotating body

A technology of rotating bodies and bulges, applied in measuring devices, rotary printing machines, rotary printing machines, etc., to achieve the effects of less personnel investment, optimized working pressure, and optimized dryer power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

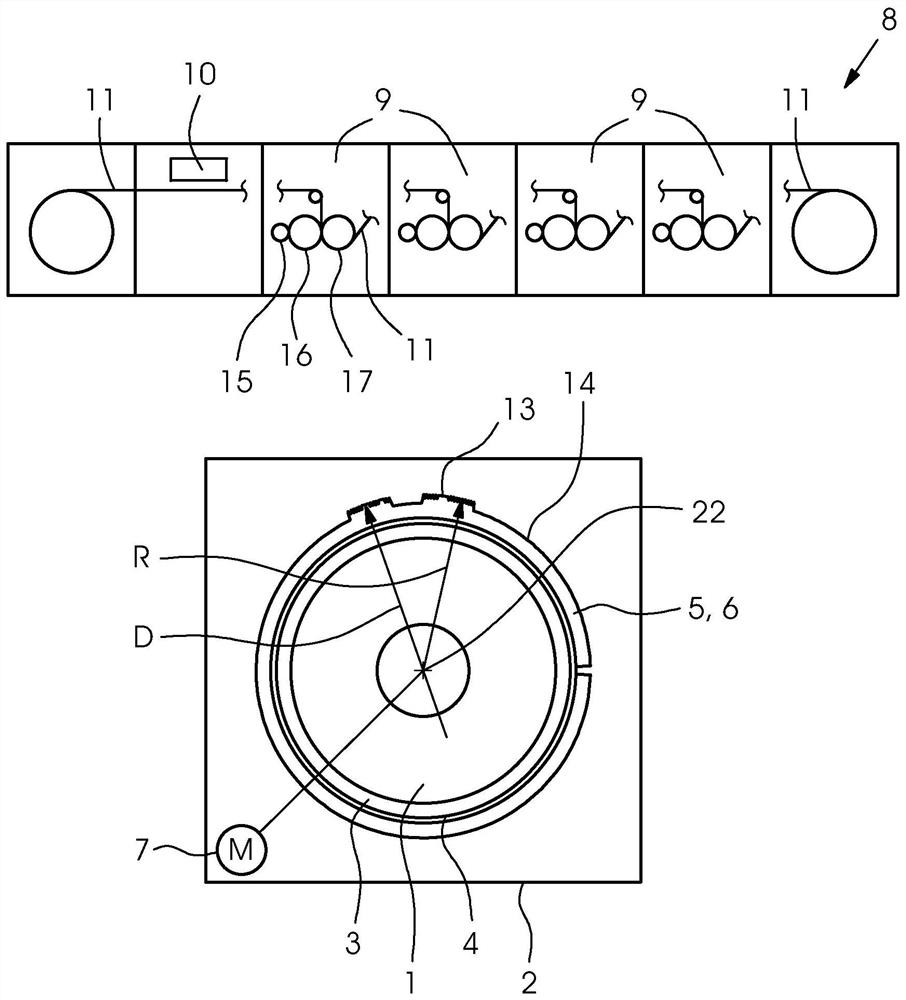

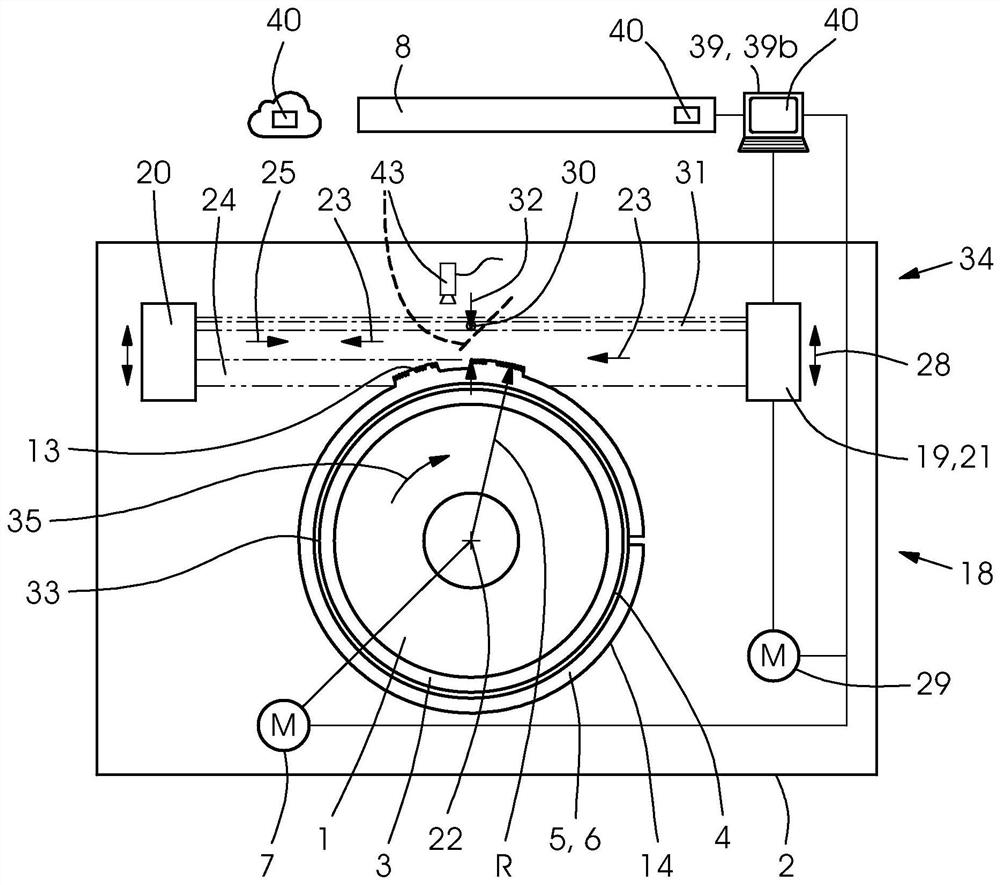

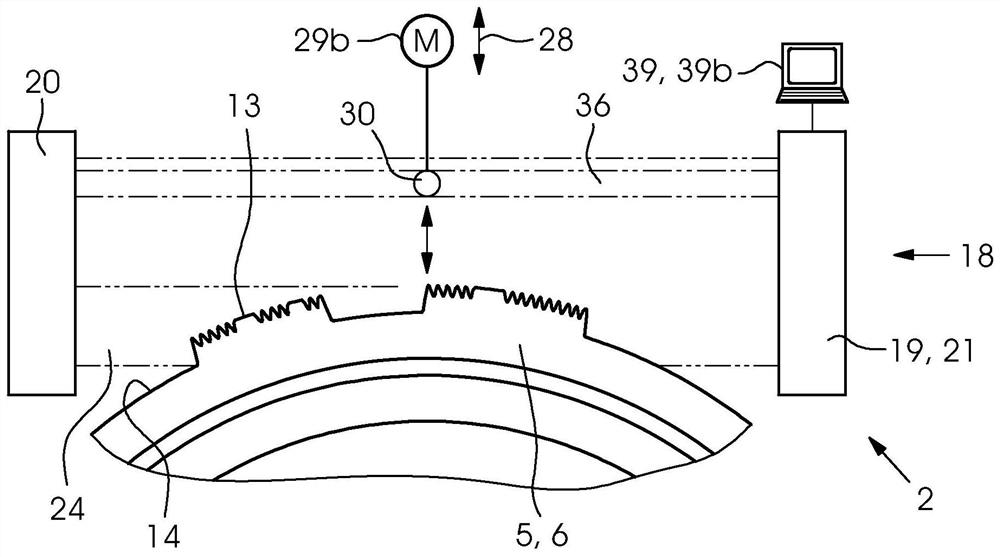

[0040] figure 1 Shown is the rotatable carrying roller 1 of the measuring station 2, the sleeve 3 accommodated on the carrying roller and the sleeve 3 accommodated on the sleeve 3, preferably by means of an adhesive tape 4 (or alternatively by means of a glue coating of the sleeve) on A printing plate 5 fixed on the sleeve 3 (the so-called “mounter”), at least with respect to its relief topography, is a cross-section of the aforementioned individual components of the rotor 6 . Alternatively, preferably laser-scribed embossing sleeves can be measured on a carrier cylinder.

[0041] In order to rotate the carrier roller 1 during the measurement, a motor 7 can be provided in the measurement station 2 . The measuring station 2 can be part of a so-called "setter" in which the printing plate 5 is mounted on a carrier sleeve, or it can be provided separately and independently from the "setter". Measuring station 2 can be arranged independently of printing press 8 , which is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com