Rear windshield defrosting device

A rear windshield and glass technology, which is applied in the field of auto parts, can solve the problems of slow defogging speed and glass cracking, and achieve the effect of small blocking effect, avoiding cracking, and eliminating uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

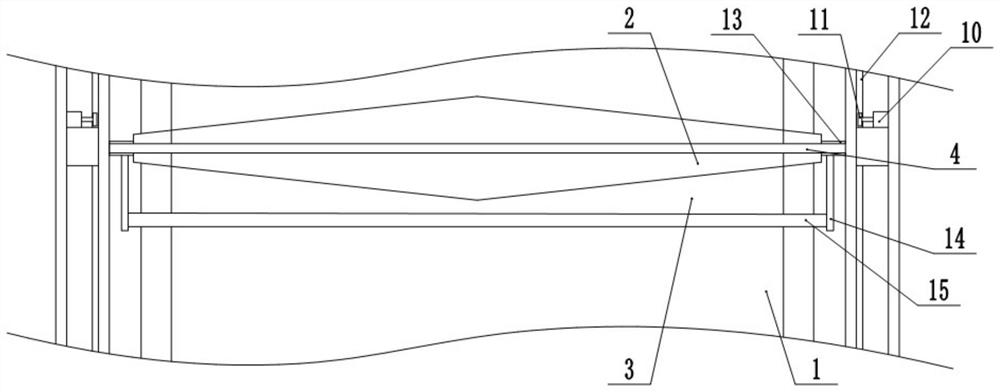

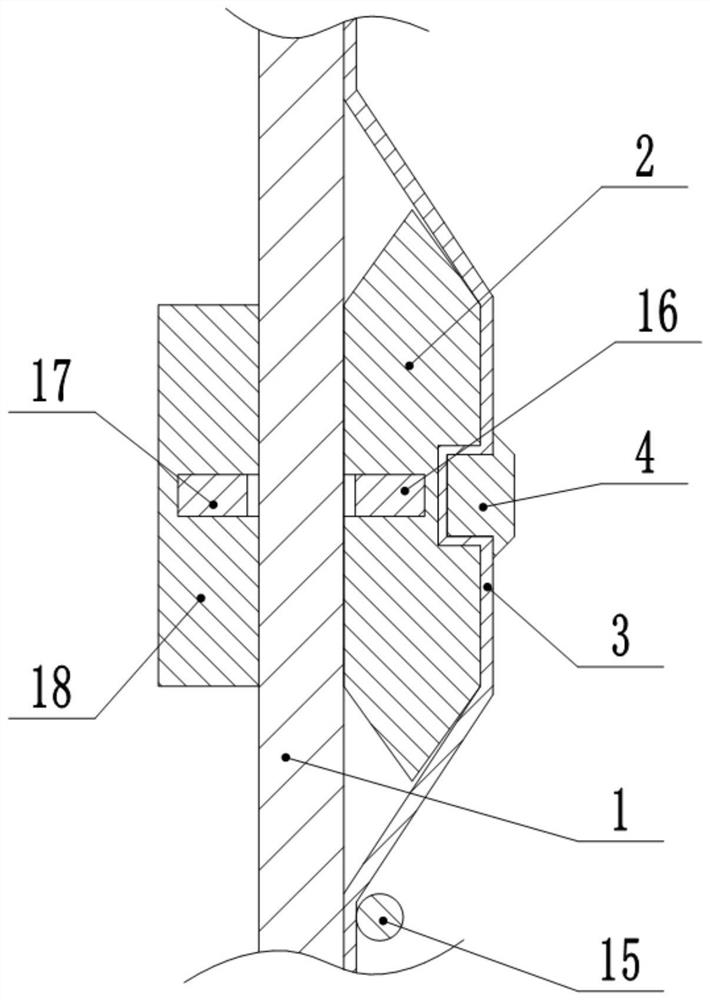

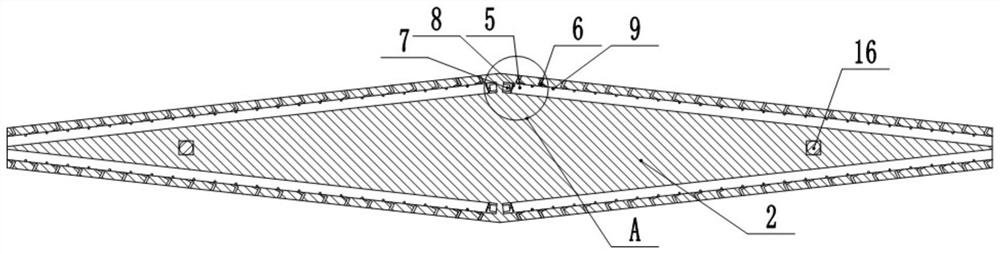

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown:

[0025] A rear windshield defrosting device, comprising a rear windshield 1 fixed on the vehicle body, vertical slide rails are arranged on both sides of the outer wall of the rear windshield 1, the slide rails are fixed on the vehicle body, and Slidingly connected with sliders, the sliders are provided with driving devices; a transparent film 3 is arranged between the sliders, and the film 3 is closely attached to the rear windshield 1, and the upper and lower ends of the film 3 are fixed on the rear windshield. On the glass 1, a top convex piece 2 is arranged between the film 3 and the rear windshield 1, the two ends of the top convex piece 2 are fixed with connecting blocks 13, and the connecting blocks 13 are respectively fixedly connected with corresponding sliders; A defrosting sheet 4 is arranged on the surface, and the defrosting sheet 4 is located at the upper end of the top convex sheet 2, and t...

specific Embodiment approach

[0026] The forward and reverse motor 10 and the drive motor 7 are started by the PLC controller, the forward and reverse motor 10 drives the drive gear 11 to rotate, and the slider is driven to reciprocate on the slide rail through the engagement between the drive gear 11 and the rack 12 .

[0027] When the slider slides, the top protruding piece 2 is driven to slide through the connecting block 13, and while the top protruding piece 2 is sliding, the top protruding piece 2 continuously lifts up the film 3, deforming the film 3, so that there is a gap between the frost and the film 3. gap, the top protruding piece 2 slides and drives the defrosting piece 4 at the same time, and the defrosting piece 4 is used to scrape off the frost; compared with the existing electric heating defogging method, this scheme has a smaller blocking effect on the field of view; at the same time This scheme does not need to heat the rear windshield 1 itself, fundamentally eliminates the uneven heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com