Automatic cutting and milling breaking device for waste fungus bag outer packing plastic films

A plastic film and outer packaging technology, which is applied in the field of fungus production waste treatment, can solve the problems of high labor intensity, high operating cost, and low operating efficiency, and achieve the effects of compact overall size, high degree of automation, and good operating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

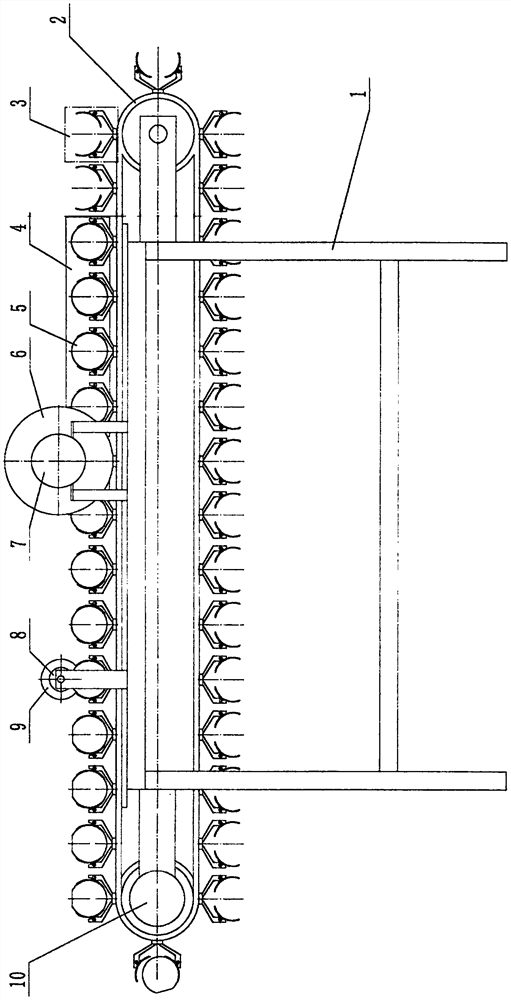

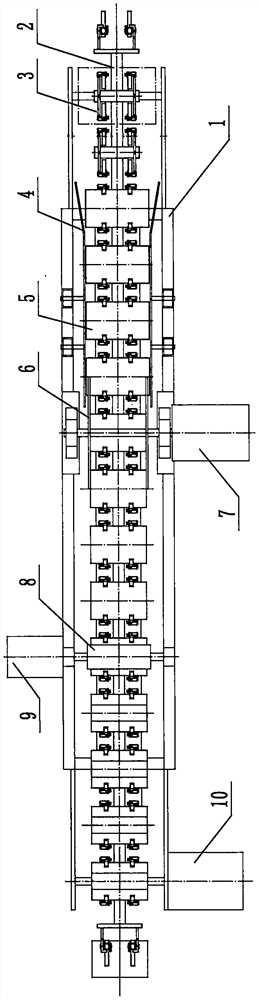

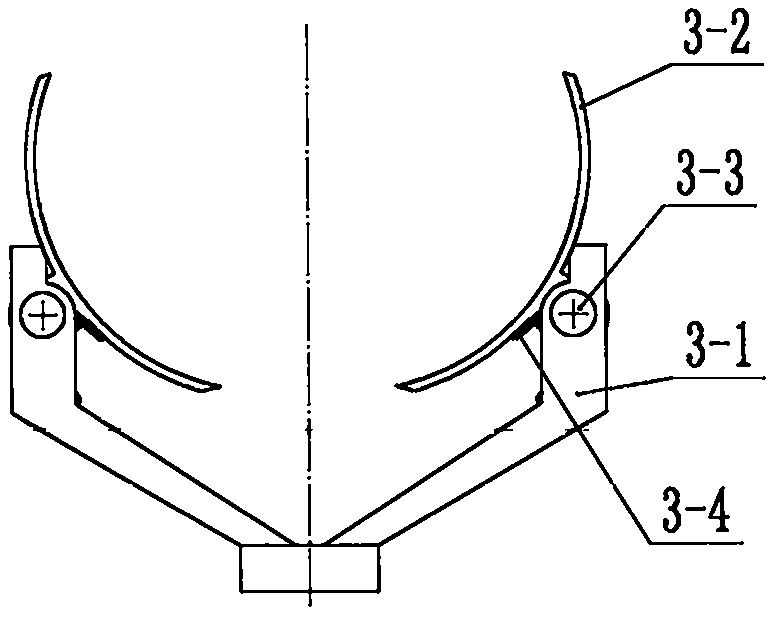

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An automatic cutting, milling and breaking device for the outer packaging plastic film of waste mushroom bags. A rotary belt assembly 2 is installed on the device frame 1, and a plurality of mushroom bags are evenly distributed and fixed on the rotary belt of the rotary belt assembly 2 to hold Assembly 3, on the front side of the device frame 1, on the outside of both sides of the rotary belt assembly 2, respectively equipped with bacteria bag axial positioning baffles 4, on the middle part of the device frame 1, located on the rotary Both sides of the belt assembly 2 are respectively equipped with disc-type cutters 6 on the end faces of the bacteria bags. Dimensions, the end face cutter driving electric motor 7 installed on the side of the device frame 1 is connected with the knife shaft of the end face disc cutter 6 of the mushroom bag, on the rear sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com