Microwave plasma chemical vapor phase deposition device

A chemical vapor deposition, microwave plasma technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of electromagnetic radiation leakage, unsatisfactory film forming effect, uneven growth of diamond film, etc. Achieve the effect of avoiding uneven growth, improving stability and avoiding perturbation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

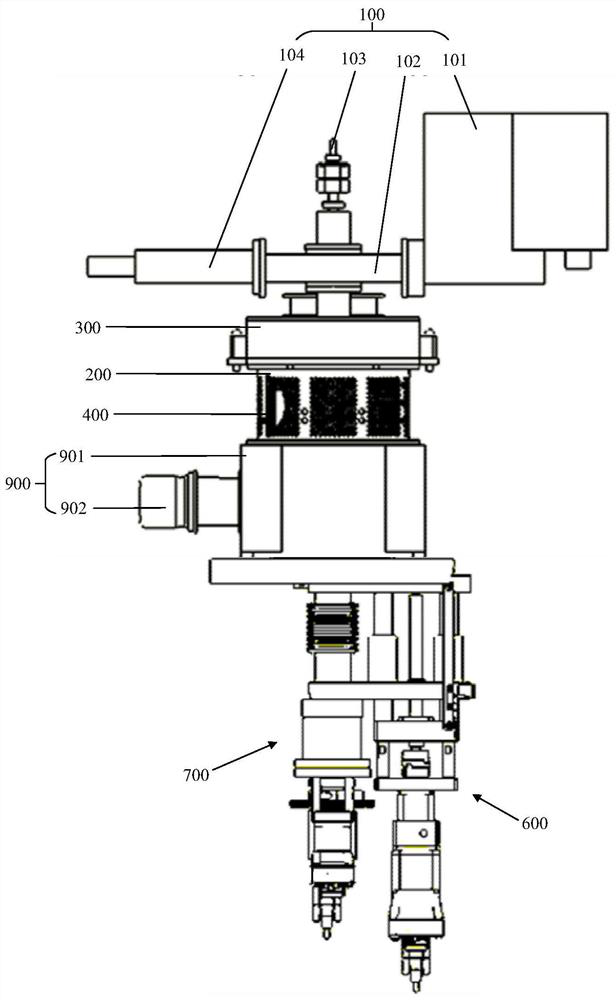

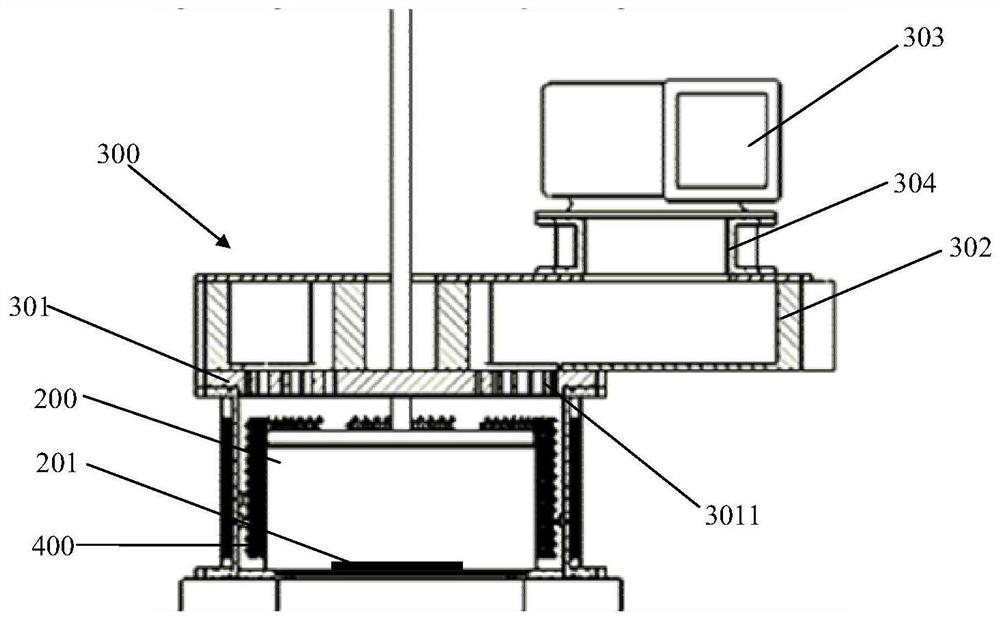

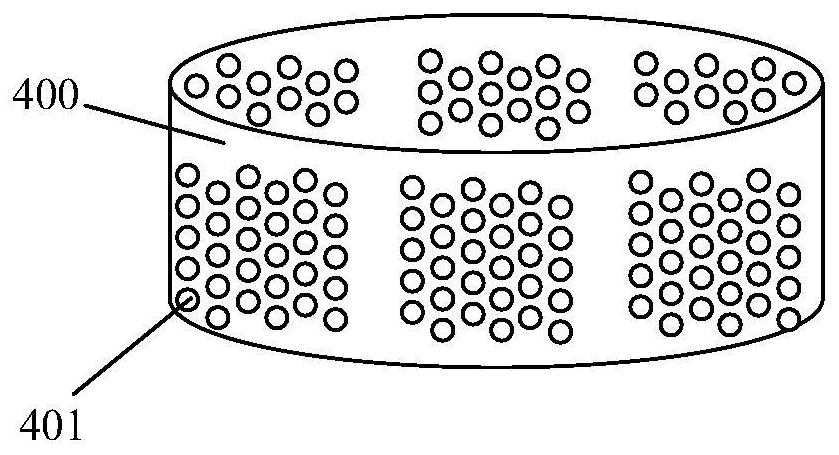

[0047] See figure 1 , figure 1 It is a microwave plasma chemical vapor deposition device. As shown in the figure, the microwave plasma chemical vapor deposition device of this embodiment includes a waveguide device 100; a reaction chamber 200 is arranged below the waveguide device 100 and is connected to the waveguide device 100; a cooling cover 300 is connected to the reaction chamber 200 and used To carry out air cooling and heat dissipation to the reaction chamber 200; the shielding cover 400 is surrounded by the outside of the reaction chamber 200 to prevent the leakage of electromagnetic radiation in the reaction chamber 200; connected so as to realize the linear motion and rotational motion of the growth platform 201 in the reaction chamber 200 .

[0048] Specifically, the waveguide device 100 is used as a microwave feeding device, including a microwave source 101 , a waveguide 102 , a microwave antenna 103 and a short-circuit piston 104 . Wherein, the microwave sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com