Microwave plasma chemical vapor deposition device

A technology of chemical vapor deposition and microwave plasma, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of affecting the quality of diamond film formation, uneven growth of diamond film, and unsatisfactory film formation effect and other problems, to achieve the effect of reducing microwave energy loss, improving utilization rate, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

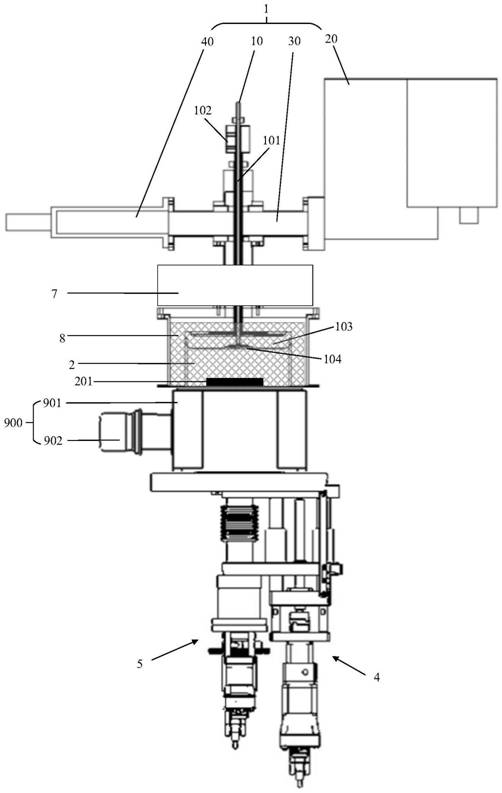

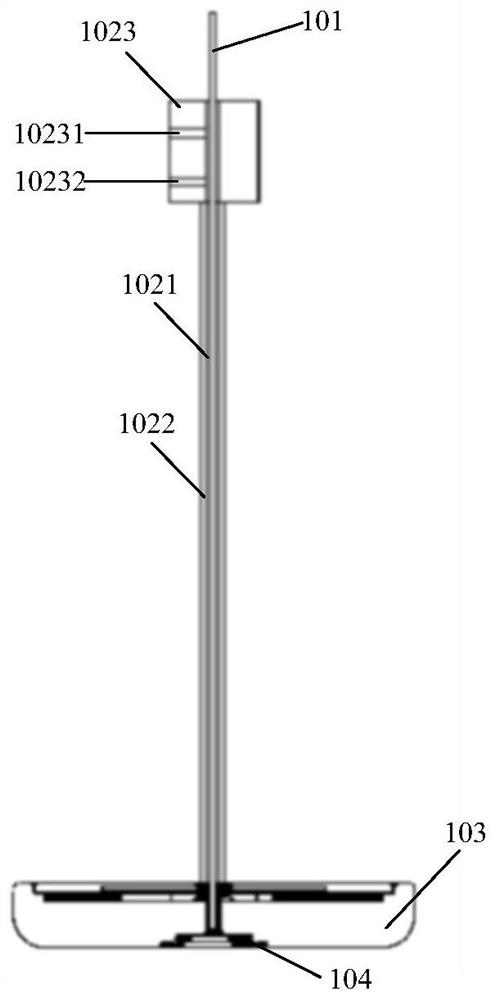

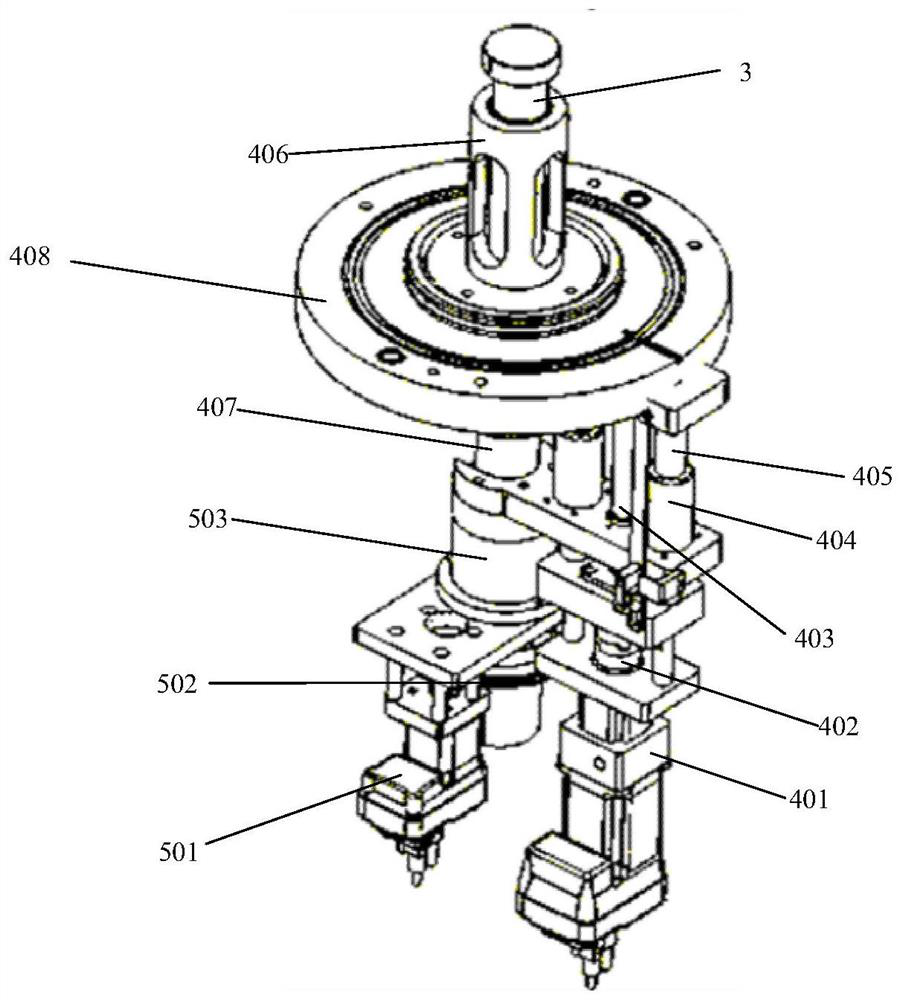

[0049] Please refer to figure 1 and figure 2 , figure 1 It is a schematic structural diagram of a microwave plasma chemical vapor deposition device provided by an embodiment of the present invention, figure 2 is a schematic structural diagram of a microwave antenna provided by an embodiment of the present invention. As shown in the figure, the microwave plasma chemical vapor deposition device of this embodiment includes: a waveguide device 1 , a reaction chamber 2 and a rotating lifting cooling mechanism. Wherein, the waveguide device 1 includes a microwave antenna 10, and the microwave antenna 10 includes an air inlet pipe 101, a water cooling structure 102, an antenna lower plate 103 and a gas distribution plate 104, wherein the water cooling structure 102 is sleeved on the outside of the air intake pipe 101; the gas distribution plate 104 It is arranged at the lower end of the antenna lower plate 103; the lower end of the air intake pipe 101 passes through the antenna ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com