A peristaltic pipeline robot

A pipeline robot, driving motor technology, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of large structural energy loss, unreliable transmission movement, complex control system, etc., to achieve low cost, improved carrying capacity, flexible good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

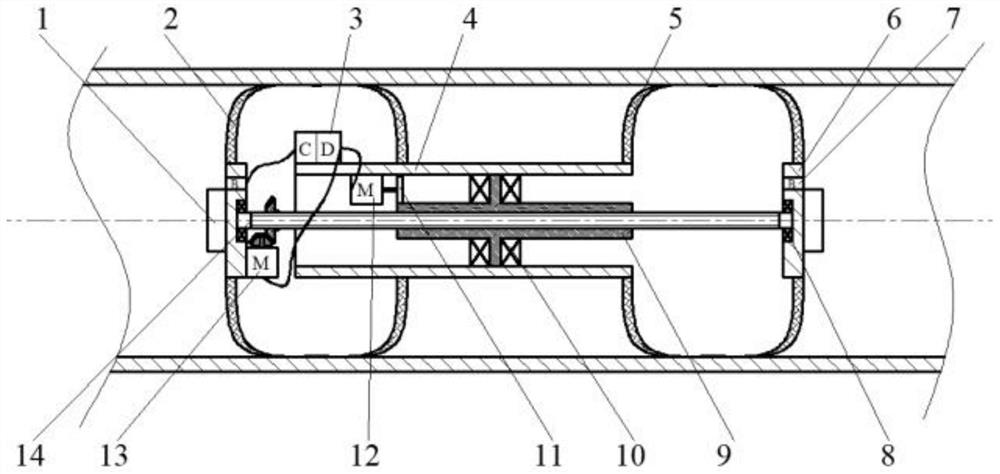

[0021] from figure 1 It can be seen that a peristaltic pipeline robot in this embodiment includes a fixed housing 4, a front airbag 2 and a rear airbag 5, and the inside of the fixed housing 4 is provided with a rotating nut 9 and a nut bearing 10, and the rotating nut 9 is connected with the fixed housing 4 through the screw sleeve bearing 10, gear teeth are arranged on the outer circle of the end face of the rotating screw sleeve 9, the outer ring of the gear teeth is engaged with the screw sleeve transmission gear 11, and the input end of the screw sleeve transmission gear 11 is provided with Screw sleeve drive motor 12, the inner circle of rotary screw sleeve 9 is provided with screw rod 14, is provided with internal thread on the inside through hole of rotary screw sleeve 9, and the outer ring of screw rod 14 is provided with external thread, and rotary screw sleeve 9 and screw rod 14 spin Together, the screw drive motor 12 drives the rotary screw sleeve 9 to rotate aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com