Hydrogen storage container and hydrogen conveying system

A hydrogen storage container and hydrogen transport technology are applied in the container filling method, the container discharge method, the installation device of the container structure, etc., and can solve the problem of reducing the hydrogen storage capacity, the rate of hydrogen storage, hydrogen release, and the hydrogen absorption capacity of hydrogen storage materials. Non-uniformity and other problems, to achieve the effect of improving the overall hydrogen absorption, uniform hydrogen absorption, and increasing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

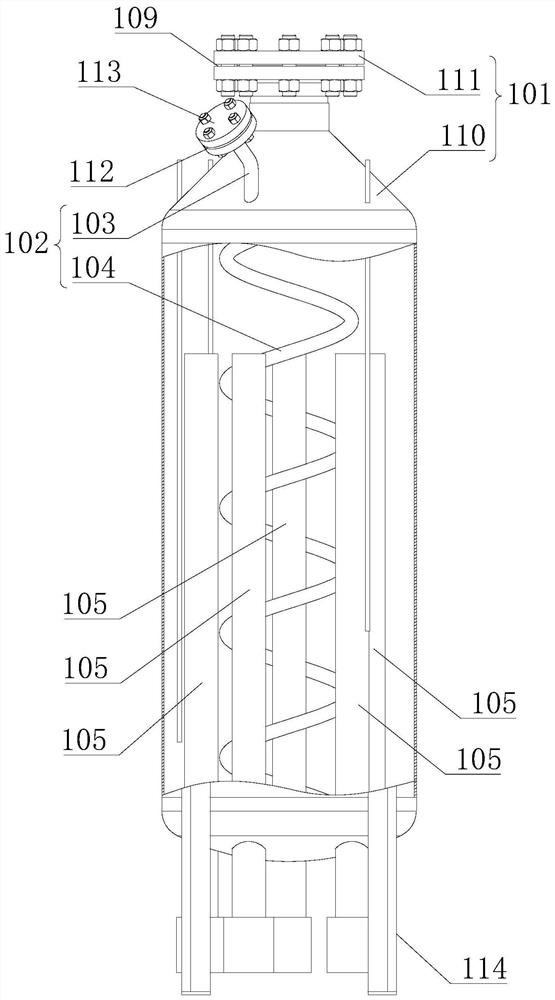

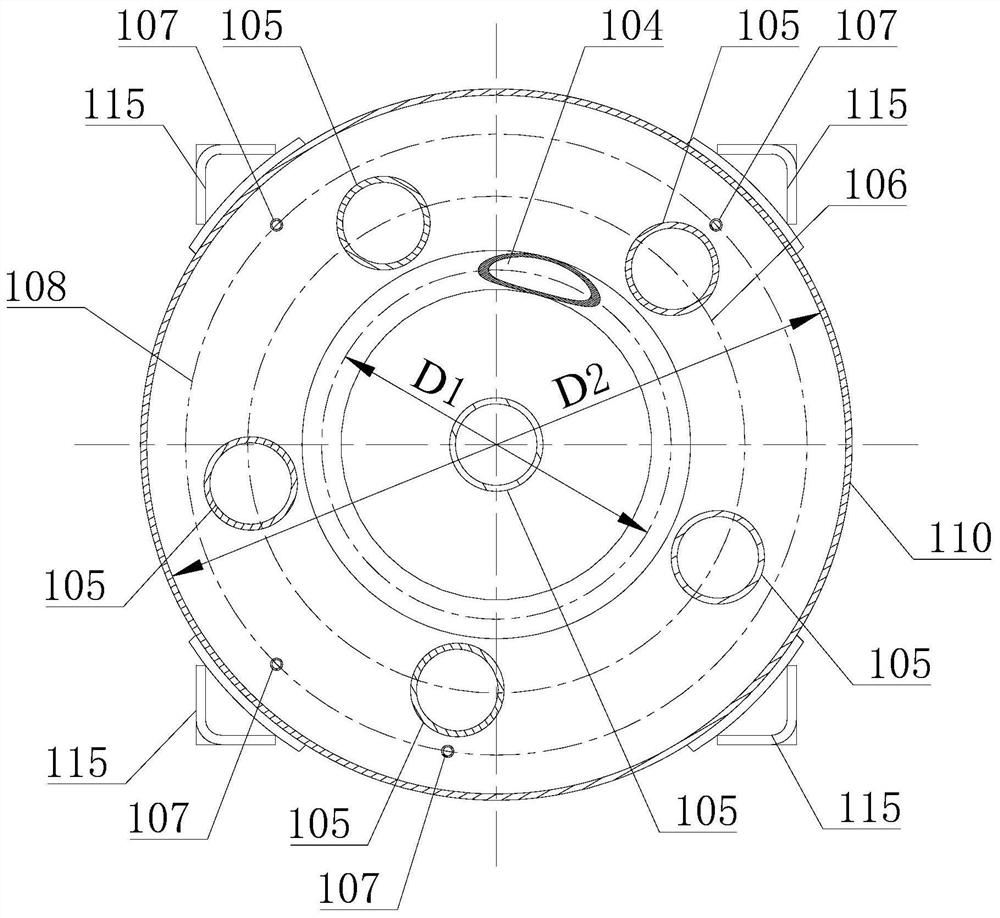

[0033] see figure 1 and figure 2 As shown, the hydrogen storage container provided by the present application includes a sealed tank 101 and an air intake pipe 102 . Wherein, the sealed tank 101 is filled with a hydrogen storage material. Preferably, the hydrogen storage material is a magnesium-based solid hydrogen storage material. The magnesium-based solid hydrogen storage method has the advantages of low pressure required for hydrogen storage and hydrogen release, and safe and convenient operation. The air intake pipe 102 runs through the sealed tank 101 , so that the hydrogen delivery equipment can transport hydrogen into the sealed tank 101 through the air intake pipe 102 .

[0034] Specifically, the intake pipe 102 includes a communicating portion 103 and a distributing portion 104 that communicate with each other. The part of the intake pipe 102 located outside the sealed tank 101 is the communicating portion 103, which is used to communicate with the hydrogen deliver...

Embodiment 2

[0048] The hydrogen storage container in the second embodiment is an improvement on the basis of the above embodiment. The technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

[0049] In an optional solution of this embodiment, the sealed tank 101 includes a tank body 110 formed with a filling port 109 and a first sealing cover 111 mounted on the filling port 109, the first sealing cover 111 is detachably connected to the tank body 110, specifically , the first sealing cover 111 and the tank body 110 can be flanged, and the first sealing cover 111 can be opened when filling materials, so that the hydrogen storage material can enter the tank body 110 from the filling port 109 .

[0050] The gas delivery port 112 of the communication part 103 is provided with a second sealing cover 113, and the second sealing cover 113 is detachably c...

Embodiment 3

[0056] Embodiment 3 of the present application provides a hydrogen delivery system, which includes the hydrogen storage container of any of the above embodiments, and thus has all the beneficial technical effects of the hydrogen storage container of any of the above embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com