Gap detection tool special for airplanes and using method

A technology for detecting tools and gaps, applied in the direction of mechanical gap measurement, etc., can solve the problems of difficult to use optical effective detection, large number of cables, crossing each other, etc., to achieve the effect of simple structure, inconvenient detection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

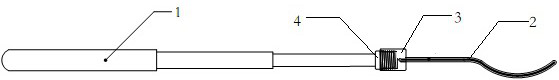

[0030] This embodiment discloses a special gap detection tool for aircraft. As a basic embodiment of the present invention, it includes a handle 1 and a detection elbow 2. The handle 1 and the detection elbow 2 are detachably connected. The connection structure can facilitate quick installation 1. Disassemble or replace the detection elbow 2. Different areas on the aircraft may have different requirements for the minimum gap, that is, the required outer diameter d of the detection elbow 2 is different. Based on the perspective of saving materials and storage space, this technical solution can realize a The handle 1 is equipped with a plurality of detection elbows 2 of different types (that is, with different outer diameters d), which further makes this technical solution applicable to many areas of the aircraft that require different clearances, and expands the scope of application of this technical solution.

Embodiment 2

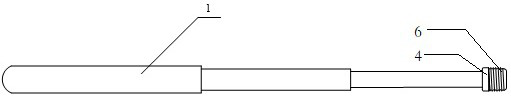

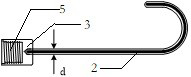

[0032] This embodiment discloses a special gap detection tool for aircraft. As a preferred embodiment of the present invention, that is, in Embodiment 1, the handle 1 is screwed to the detection elbow 2, and further, the handle 1 is provided with a connection Seat 3, the detection elbow 2 is provided with a connector 4, or the detection elbow 2 is provided with a connector 3, and the handle 1 is provided with a connector 4; the center of the connector 3 is provided with a spiral groove 5, and the connector 4 is provided with Corresponding to the spiral groove 5 is an external helical structure 6; the handle 1 is a telescopic rod structure; the detection elbow 2 includes a metal strip 2.1 made of alloy material and a protective layer 2.2 wrapped outside the metal strip 2.1, The protective layer 2.2 is made of plastic material or rubber material.

[0033] In this technical solution, the connection between the connecting elbow and the handle 1 is connected by a spiral structure, ...

Embodiment 3

[0035] This embodiment discloses a method of using a gap detection tool, as a basic implementation of the present invention, including gap qualified detection, the detection tool includes a handle 1 and a detection elbow 2, and the handle 1 and the detection elbow 2 Detachable connection; hold the handle 1 and extend the detection elbow 2 into the gap. If the detection elbow 2 cannot be smoothly inserted into the gap, it indicates that the gap width is unqualified. If the detection probe can enter the gap smoothly, the detection bend The head 2 moves along the extending direction of the gap. If the movement is smooth, it indicates that the gap is qualified, otherwise, it indicates that the gap is unqualified.

[0036] The technical solution discloses the principle and specific implementation of gap detection by using a gap detection tool. The implementation is fast and effective, and the detection result is effective and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com