Control method of high-pressure hydrogen storage system

A control method and high-voltage technology, which is applied in the direction of reactant parameter control, fuel cell additives, fuel cells, etc., can solve problems such as high risk, poor product reliability, and low product maturity, so as to improve operation safety and prevent failures. The effect of improved adaptability and simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

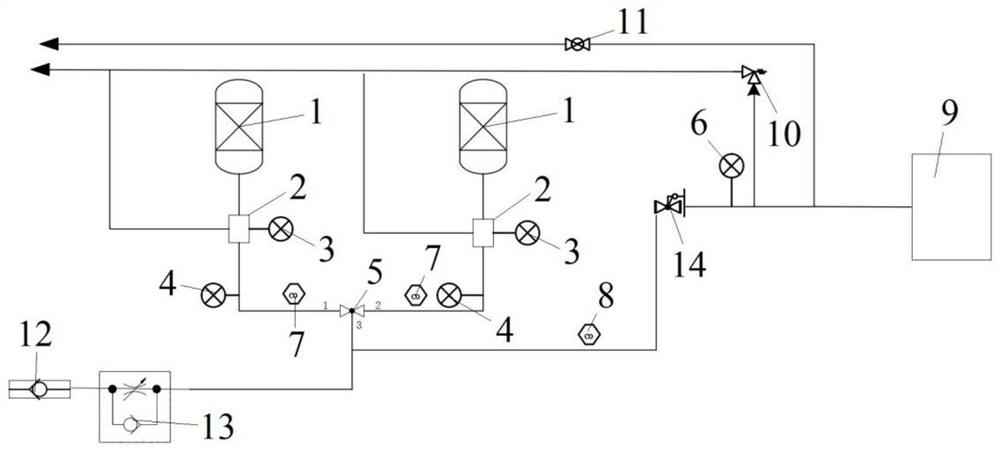

[0028] Such as figure 1 As shown, it is a schematic structural diagram of the high-pressure hydrogen storage system of this embodiment. The high-pressure hydrogen storage system of this embodiment includes two sets of high-pressure hydrogen storage bottles 1. In actual use, it is not limited to two sets of high-pressure hydrogen storage bottles 1, and can be more than two sets of high-pressure hydrogen storage bottles. As long as the hydrogen supply function of this embodiment can be realized. The outlet of the high-pressure hydrogen storage bottle 1 is provided with a bottle valve 2. The bottle valve 2 is a three-way valve. There is a first pressure sensor 3 for monitoring the pressure in the high-pressure hydrogen storage bottle 1, the inlet end of the hydrogen supply pipeline is connected to the bottle valve 2, and the outlet end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com