Anti-impact heating type main control box

A heating, main control box technology, applied in cooling/ventilation/heating transformation, modification by conduction heat transfer, chassis/cabinet/drawer parts, etc., can solve the problem of increasing grid connection cost and prolonging grid connection. Cycle, PCB board damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

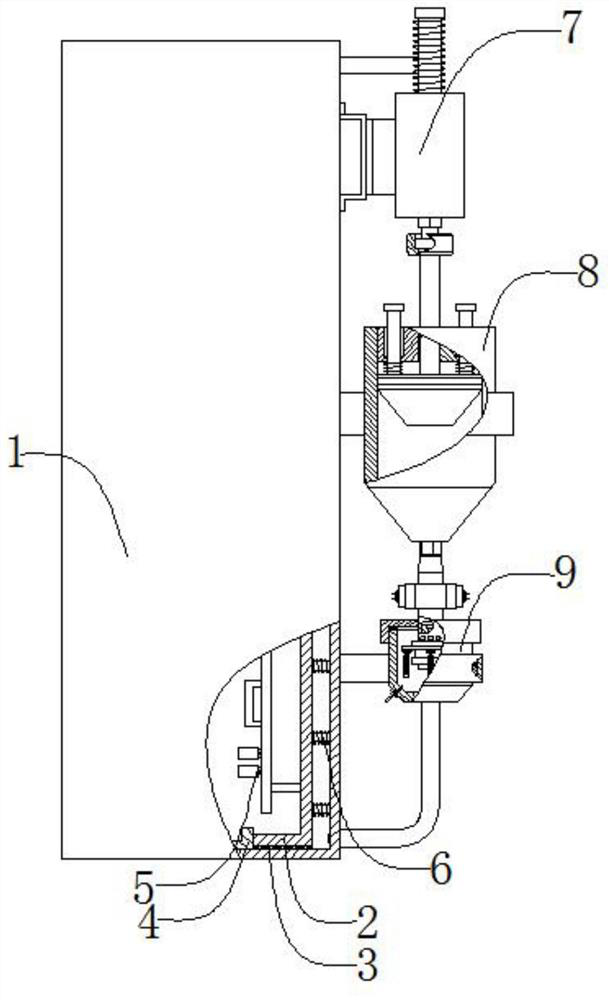

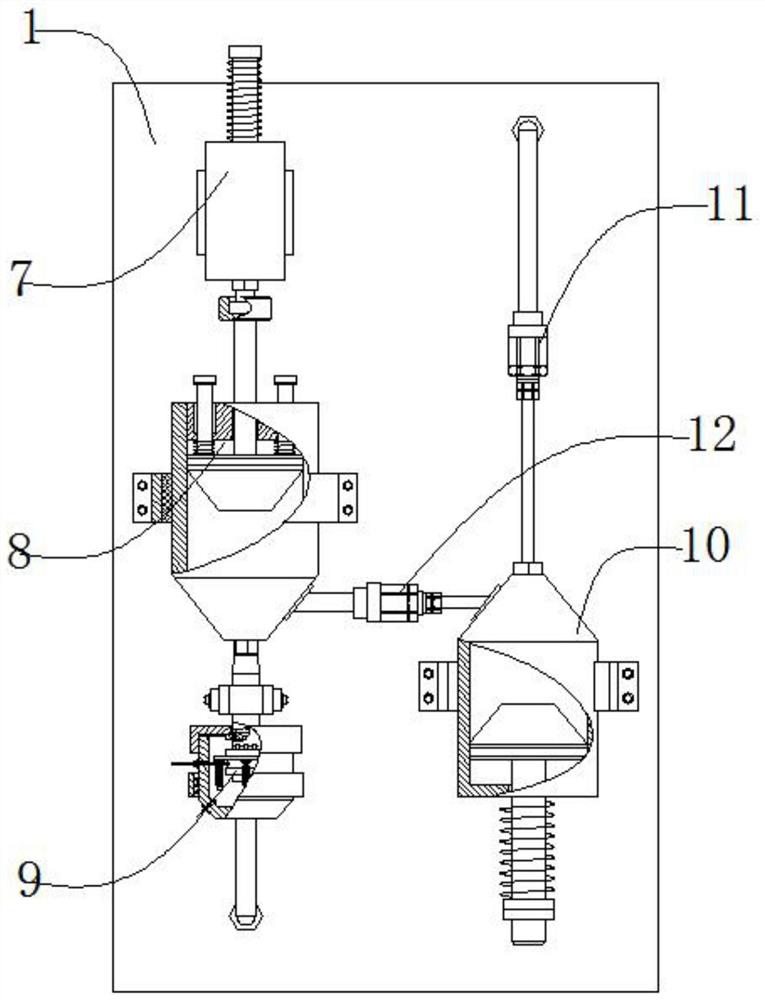

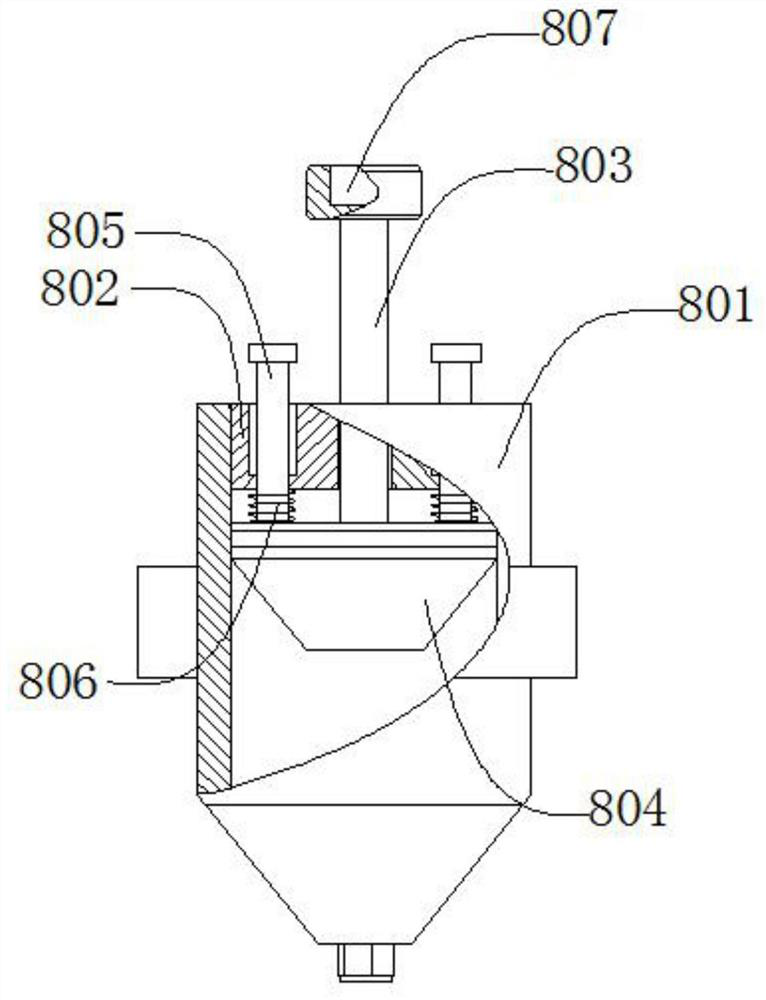

[0021] Such as Figure 1 to Figure 7As shown, an impact-resistant heating main control box includes an outer box body 1, an inner box body 2, a sealing sleeve 3, a stopper 4, a PCB board 5, a compression spring 6, a long-stroke electromagnet 7, and an extrusion mechanism 8 , a vibration heating mechanism 9, a buffer mechanism 10, a first one-way valve 11, a second one-way valve 12, the inner box 2 is set inside the outer box 1, and the sealing sleeve 3 is located between the outer box 1 and the second one-way valve 12. Between the inner box body 2, the sealing sleeve 3 is connected with the inner box body 2 through interference fit, the said stopper 4 is located inside the outer box body 1 and outside the inner box body 2, and the said stopper head 4 is connected with the inner box body 2. The outer box 1 is connected by bolts, the PCB board 5 is located inside the inner box 2, the PCB board 5 is connected with the inner box 2 by bolts, and the compression spring 6 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com