Shunting, guiding and uniform scattering device for realizing large-breadth-coverage returning of straw

A throwing device and a large-scale technology, which is applied in the direction of crop processors, cutters, agricultural machinery and implements, etc., can solve the problems of uneven coverage, lack of seedlings and weak seedlings of crops, covering and returning to the field, etc., and achieve simple and uniform adjustment structure design Easy to spread and adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

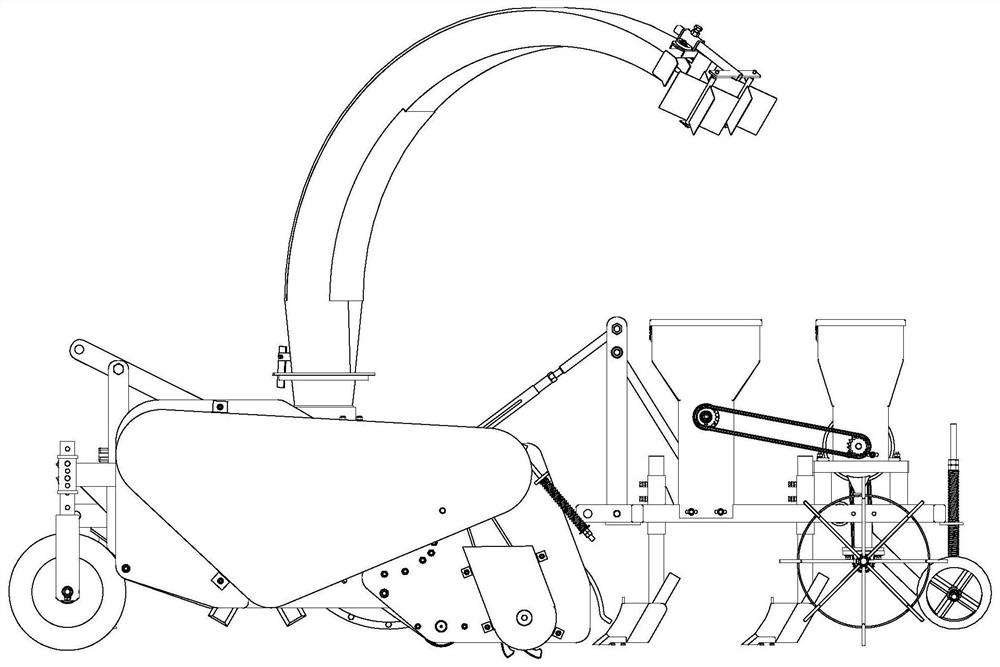

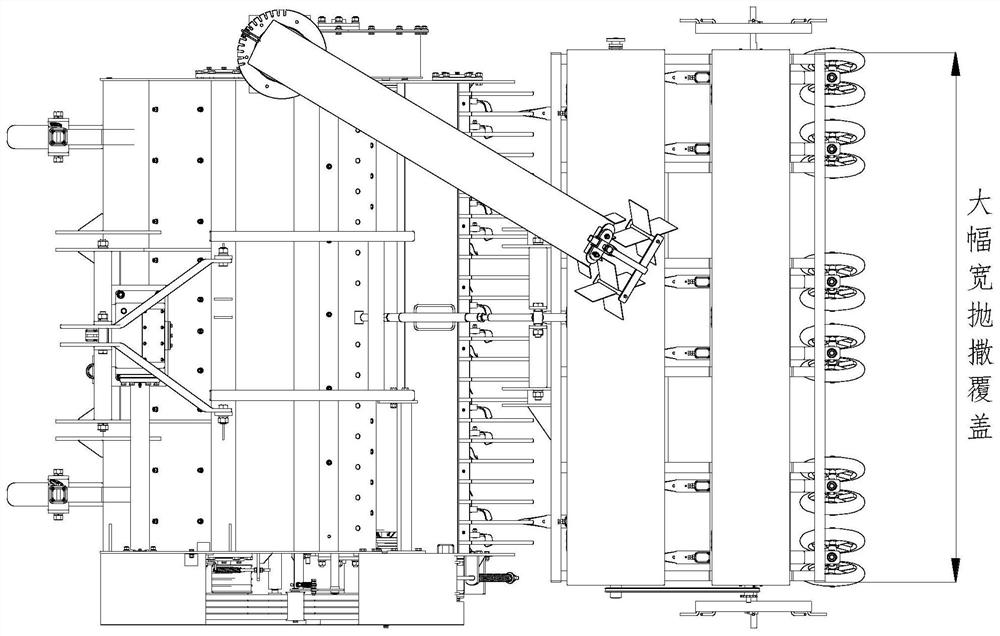

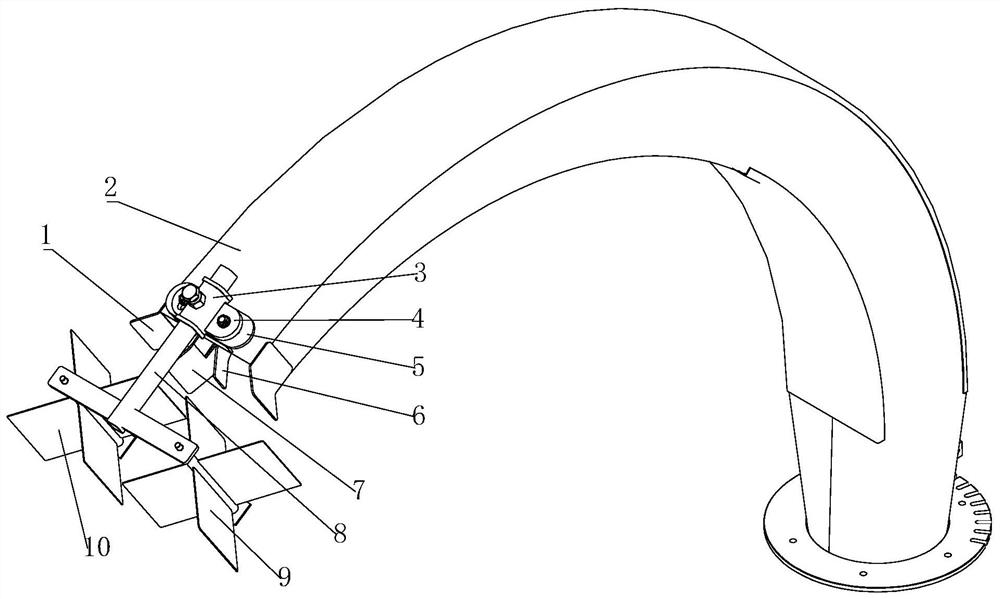

[0024] see Figure 1-Figure 5 , the shunt-guided uniform throwing device for realizing the large-scale and wide coverage of the straw is composed of a support mounting frame 5, a left and right adjustment base 4, a front and rear adjustment rod stand 3, a limit plate 7, an impeller installation adjustment rod 8, and a left-rotating impeller assembly 10 1. The right-hand rotating impeller assembly 9 is formed, and is assembled in the broken straw throwing port 2 of the machine tool.

[0025] The top of the broken straw throwing port 2 is centered and welded to fix the support mounting frame 5, and the support mounting frame 5 is designed with 2 long holes for adjustment;

[0026] Such as Figure 3-4 As shown, two outer guide plates 1 are respectively welded and fixed on both sides of the straw throwing port 2, which are used to limit the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com