Brewing method of selenium-rich soy sauce with high glutamic acid content

A technology of selenium-enriched soy sauce and high glutamic acid is applied in the function of food ingredients, food science, application, etc., to achieve the effect of improving natural freshness, promoting the improvement of body immunity, and rich sauce flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

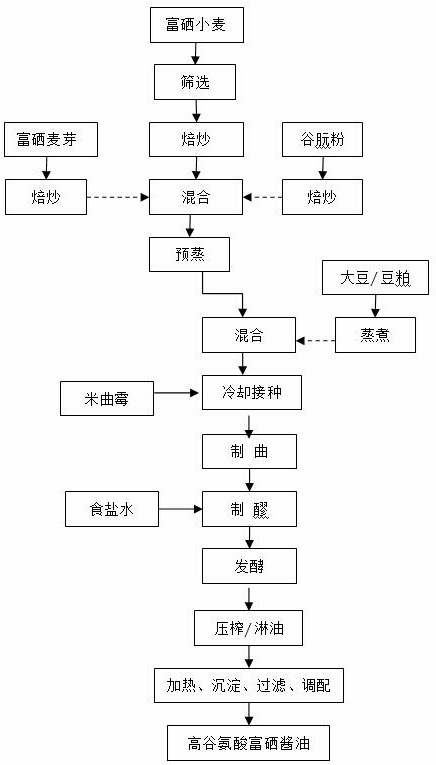

Method used

Image

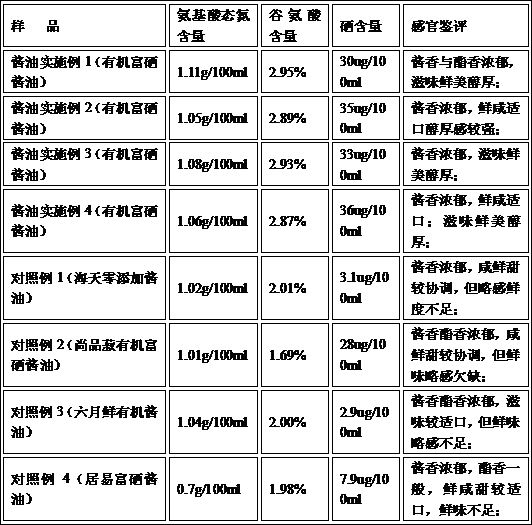

Examples

preparation Embodiment 1

[0037] High-salt dilute state low-temperature fermentation preparation process using soybeans, selenium-enriched wheat, gluten, organic selenium malt and other raw materials:

[0038] ⑴Materials: drinking water, soybeans, selenium-enriched wheat, gluten, salt, organic selenium malt, Aspergillus oryzae koji;

[0039] (2) First, screen soybeans and flatten them into soybean flakes with a thickness of 1-2mm; add 0.9-1 times the weight of soybeans in hot water at 68-88°C for 6-45 minutes, cook at a cooking pressure of 0.15-0.18MP and a temperature of 125- Cook at 128°C for 4-10 minutes, then cool for later use;

[0040] (3) Take 50-90% of the soybean weight of selenium-enriched wheat, and roast it according to the conventional process; take another 10-20% of the soybean weight of gluten powder; 1-5% of the soybean weight of organic selenium malt, at 120-360°C Roast for 10-60 minutes respectively. Cool and crush the roasted selenium-enriched wheat and organic selenium malt, sieve...

preparation Embodiment 2

[0044] High-temperature fermentation preparation process of medium-salt dilute mash with defatted soybeans (soybean meal), selenium-enriched wheat, gluten, and organic selenium malt:

[0045] ⑴Materials: drinking water, defatted soybeans (soybean meal), selenium-enriched wheat, gluten, salt, Aspergillus oryzae seed koji;

[0046] (2) First, screen defatted soybeans (soybean meal) to remove agglomerates and sundries; add 1.2 to 1.3 times the weight of defatted soybeans (soybean meal) in hot water at 68 to 88°C for 6 to 45 minutes, cook at a cooking pressure of 0.16 to 0.18MP, Cook at a temperature of 125-128°C for 4-10 minutes, then cool for later use;

[0047] (3) Take 50-90% of the weight of defatted soybeans (soybean meal) and roast selenium-enriched wheat according to the conventional process; take another 10-20% of the weight of defatted soybeans (soybean meal) Gluten powder; 1-5% of the weight of defatted soybeans (soybean meal) Organic selenium malt is roasted at 120-36...

preparation Embodiment 3

[0051] Preparation process of high-salt dilute pouring fermentation with defatted soybeans (soybean meal), selenium-enriched wheat, gluten and other raw materials:

[0052] ⑴Raw materials: drinking water, defatted soybeans (soybean meal), selenium-enriched wheat, gluten, salt, organic selenium malt, Aspergillus oryzae koji;

[0053] (2) First, screen defatted soybeans (soybean meal) to remove agglomerates and sundries; add 1.2 to 1.3 times the weight of defatted soybeans (soybean meal) in hot water at 68 to 88°C for 6 to 45 minutes, cook at a cooking pressure of 0.16 to 0.18MP, Cook at a temperature of 125-128°C for 4-10 minutes, then cool for later use;

[0054] (3) Take 50-90% of the weight of defatted soybeans (soybean meal) and roast selenium-enriched wheat according to the conventional process; take another 10-20% of the weight of defatted soybeans (soybean meal) Gluten powder; 1-5% of the weight of defatted soybeans (soybean meal) Organic selenium malt is roasted at 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com