Femtosecond laser processing system and method for realizing polyimide ablation or carbonization

A femtosecond laser processing and femtosecond laser technology, applied in the field of femtosecond laser applications, can solve the problems of inaccurate repositioning, inability to meet ablation and carbonization, and secondary clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

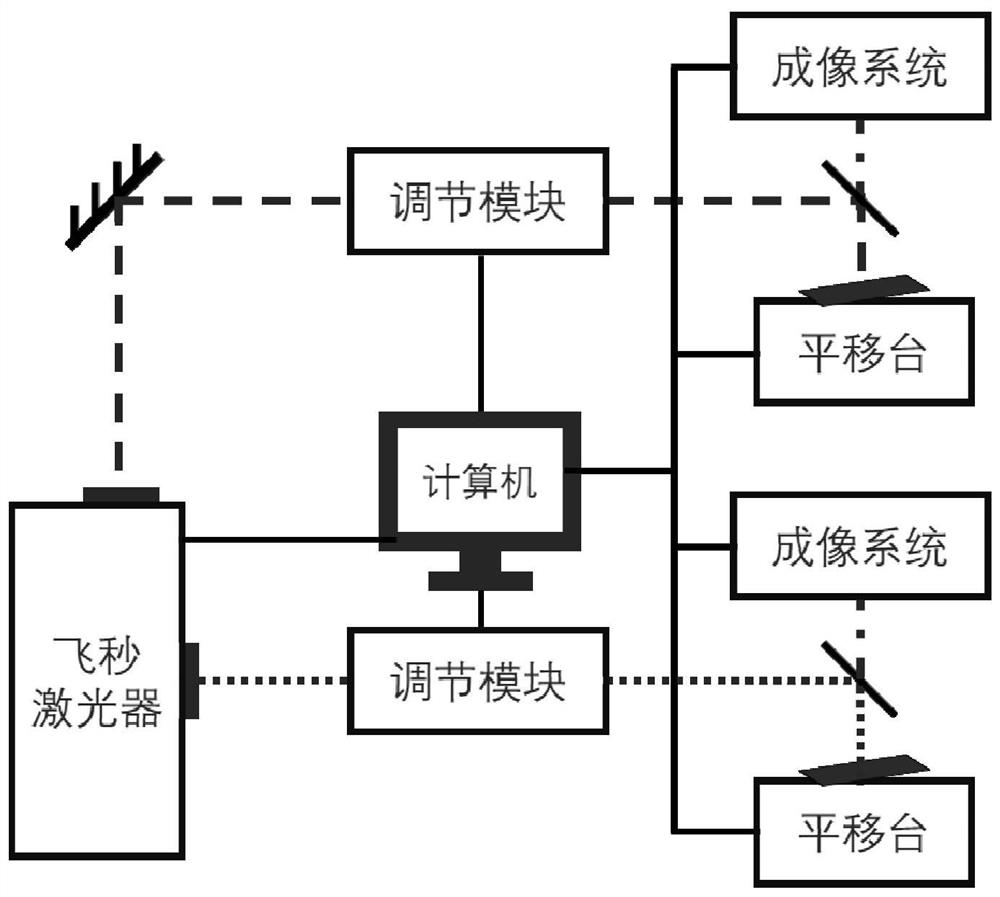

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

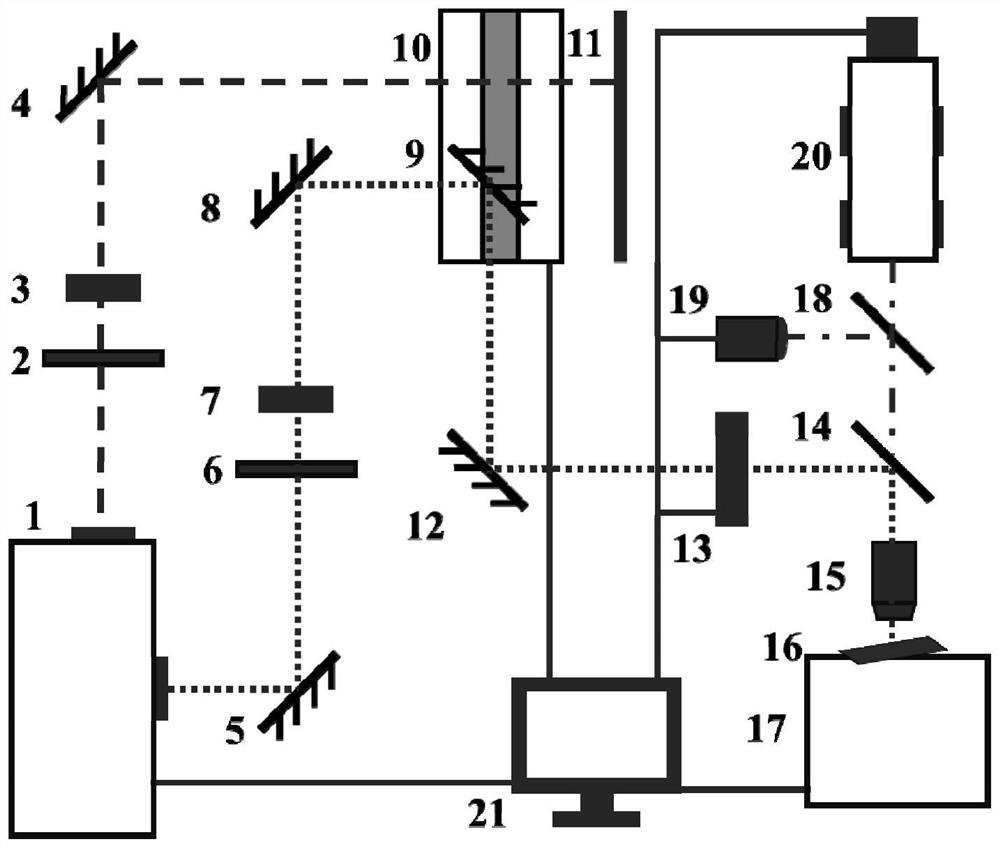

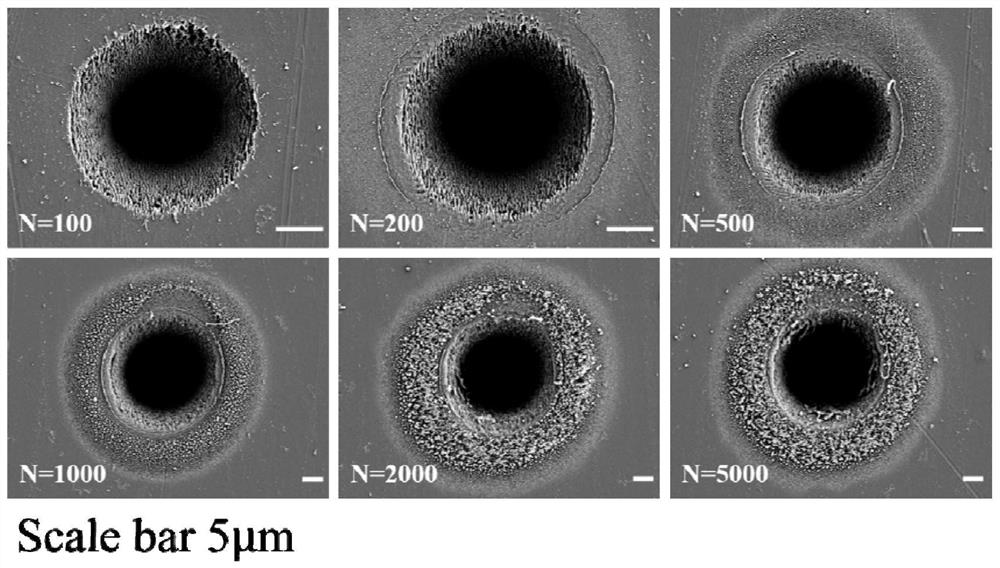

[0030] Dot processing of ablation and removal properties is performed on the surface of PI sample 16. First, femtosecond laser 1 is turned on to generate femtosecond laser, and computer 21 is used to control the moving position of one-dimensional translation stage 10, so that the amplifier laser is reflected by fourth mirror 9. Adjust the laser power through the first attenuation sheet 2, so that the laser flux is 1.2J / cm 2 , adjust the spot size to 8mm through the first aperture 3; turn on the illuminating lamp 19, adjust the position of the CCD 20 so that it can image clearly; adjust the position of the processing objective lens 15 to focus the femtosecond laser on the surface of the PI sample 16. Use the computer 21 to set the opening time of the electronically controlled shutter 13 to 100 ms, open the shutter, so that the surface of the PI sample 16 produces an ablation processing effect; use the computer 21 to control the six-dimensional translation stage 17 to translate 5...

Embodiment 2

[0033] Carry out carbonization scanning line on the surface of PI sample 16, process continuous carbonization structure, first turn on femtosecond laser 1 to generate femtosecond laser, use computer 21 to control the moving position of one-dimensional translation stage 10, so that the oscillator laser is reflected by the fourth mirror 9 . Regulating the laser power by the second attenuation plate 6 is 80mW, and the spot size is 8mm by the second diaphragm 7; Turn on the illuminator 19, adjust the position of the CCD 20 so that it can be clearly imaged; adjust the position of the processing objective lens 15 to make the femtosecond The laser is focused on the surface of PI sample 16 . Use the computer 21 to set the electronically controlled shutter 13 as a continuous open mode, and set the translation speed of the six-dimensional translation stage 17 to 1000 μm / s; open the shutter to make the surface of the PI sample 16 produce the effect of carbonization and sweeping lines; us...

Embodiment 3

[0036] Process the interdigitated microcapacitor on the surface of PI sample 16, first turn on the femtosecond laser 1 to generate femtosecond laser, and adjust the laser flux of the amplifier to 1.2J / cm through the first attenuator 2 2 , adjust the spot size to 8mm through the first aperture 3; adjust the oscillatory laser power to 60mW through the second attenuation plate 6, adjust the spot size to 8mm through the second aperture 7; use the computer 21 to control the moving position of the one-dimensional translation stage 10 , so that the oscillating pole laser is reflected by the fourth mirror 9 . Turn on the illuminator 19, adjust the position of the CCD 20 so that it can image clearly; adjust the position of the processing objective lens 15 to focus the femtosecond laser on the surface of the PI sample 16. Use the computer 21 to set the electronically controlled shutter 13 to the continuous open mode, set the translation speed of the six-dimensional translation stage 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com