A clamping and fixing device for automobile welding and its application method

A technology of clamping and fixing and clamping device, which is applied to welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of parts sliding up and down, unable to be welded in automobiles, reducing welding efficiency, etc., and achieve the effect of avoiding jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

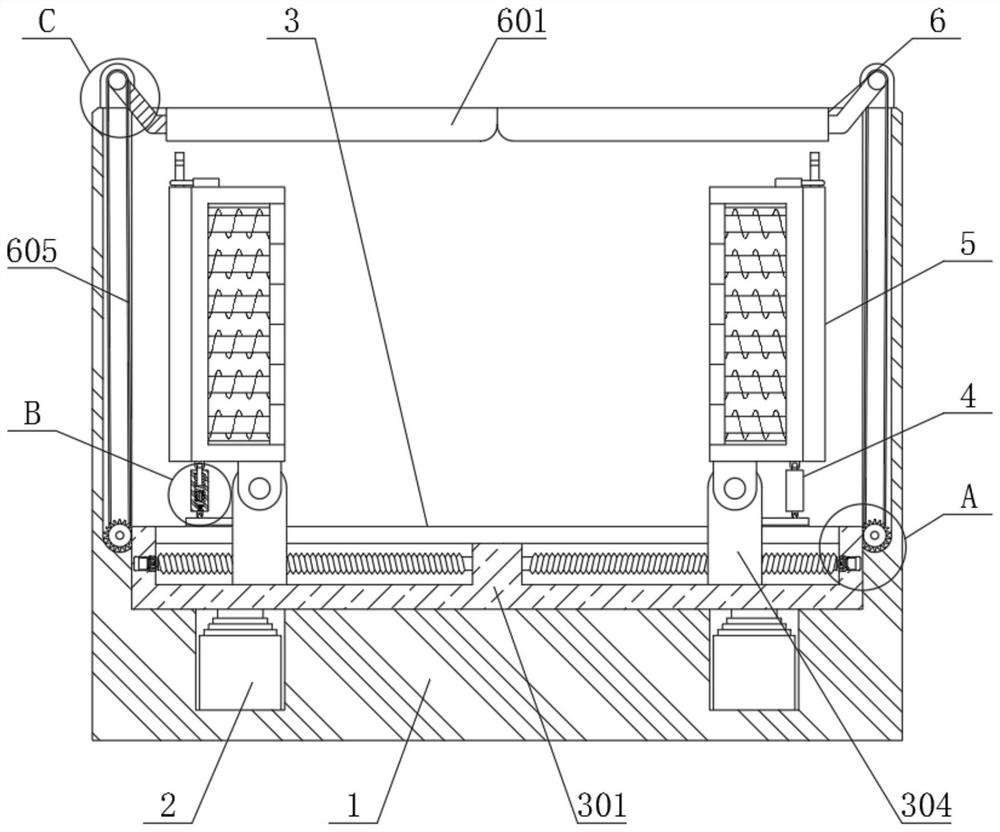

[0033] see Figure 1-7 , the present invention provides a technical solution:

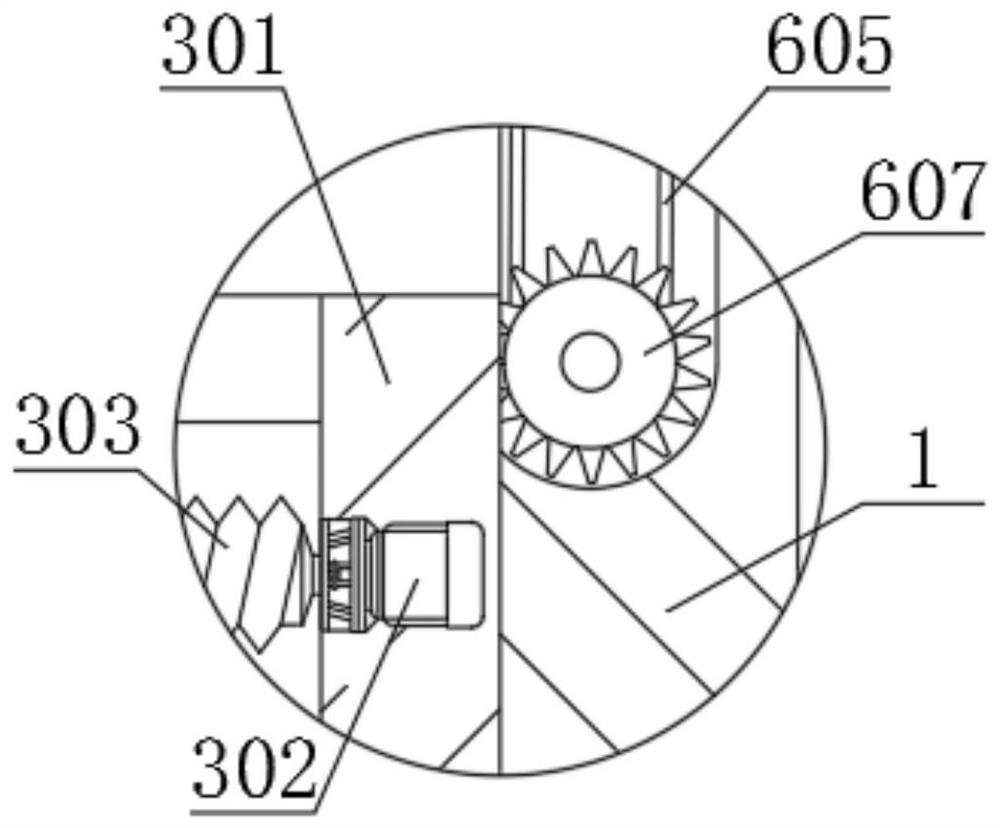

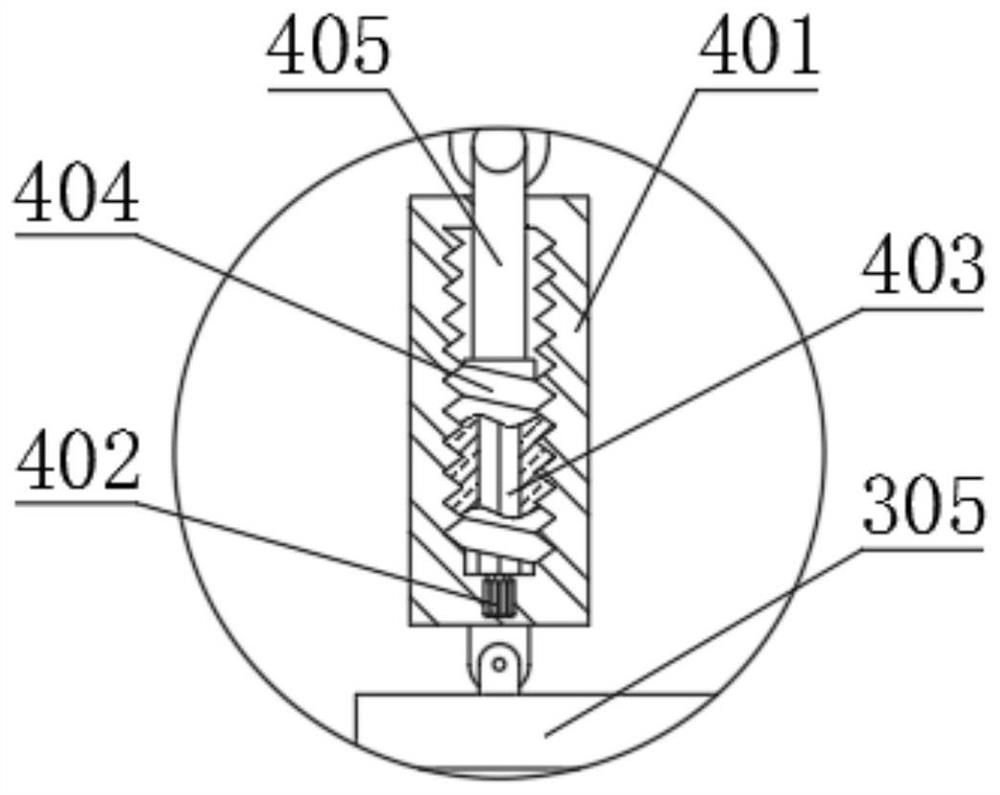

[0034]A clamping and fixing device for automobile welding and its use method, comprising a clamping device shell 1 and a clamping and fixing device 5, the inner side of the bottom end of the clamping device shell 1 is fixedly connected with a multi-stage electric telescopic rod 2, and the multi-stage electric telescopic rod 2 The top of the rod 2 is provided with a lifting device 3. This setting drives the lifting device 3 to lift through the multi-stage electric telescopic rod 2. The lifting device 3 includes a lifting plate 301, a threaded rod 303, a threaded rod 303, a sliding block 304 and a fixed plate 305. , the top of the lifting device 3 is provided with a clamping and fixing device 5, the clamping and fixing device 5 includes a clamping seat 501, a slide bar 502, a clamping plate 503, a spring 504, a limit plate 505 and a connecting rope 506, the lifting device 3 and An angle adjustment d...

Embodiment 2

[0038] see Figure 1-7 , the present invention provides a technical solution:

[0039] A clamping and fixing device for automobile welding and its use method, the same parts in embodiment 2 as in embodiment 1 will not be repeated in the present invention, and the difference lies in the work flow.

[0040] Work process: the present invention is powered by an external power supply before use, firstly start the multi-stage electric telescopic rod 2 to drive the lifting device 3 to move upward, so that the lifting device 3 drives the clamping and fixing device 5 to protrude from the top surface of the clamping device shell 1 , and during the upward movement of the lifting device 3, the lifting device 3 drives the gear 607 to rotate through the engagement with the gear 607, the gear 607 drives the second roller 606 to rotate, and drives the first roller 604 to rotate under the transmission of the transmission belt 605 After the first roller 604 rotates, it will drive the top cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com