Pyrography painting with multi-layer brightness and manufacturing process thereof

A production process, multi-level technology, applied in the direction of coating, special paper, decorative art, etc., can solve the problems of shrinkage of base material layer, limit of pattern fineness, curling, etc., to achieve uniform pattern, improve aesthetics, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

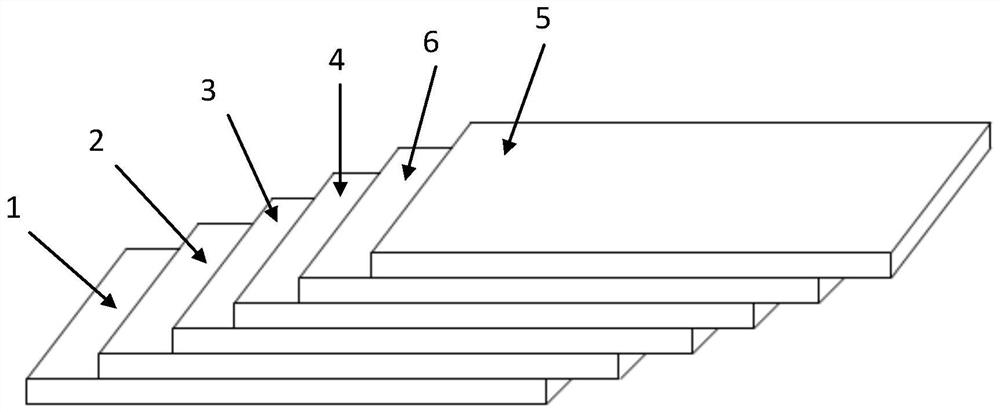

[0040] The invention provides a kind of magic gold hot stamping for textiles, such as figure 1 shown, including:

[0041] A base material layer 1;

[0042] A barrier layer 2, partially covering the upper surface of the base material layer 1, so that the part of the barrier layer 2 shielding the base material layer 1 presents a flat effect;

[0043] A color layer 3, arranged on the upper surface of the barrier layer 2;

[0044] A transparent elastic layer 4, arranged on the upper surface of the color layer 3;

[0045] A glue layer 5 is arranged on the upper surface of the transparent elastic layer 4 .

[0046] Specifically, in this embodiment, the base material layer 1 can be made of PET (Polyethylene terephthalate, polyethylene terephthalate) material or PE (polyethylene, polyethylene) material or paper material, and the material of the barrier layer 2 is Silicone release agent, the function of the barrier layer 2 is to prevent the refraction of incident light. Therefore, ...

Embodiment 2

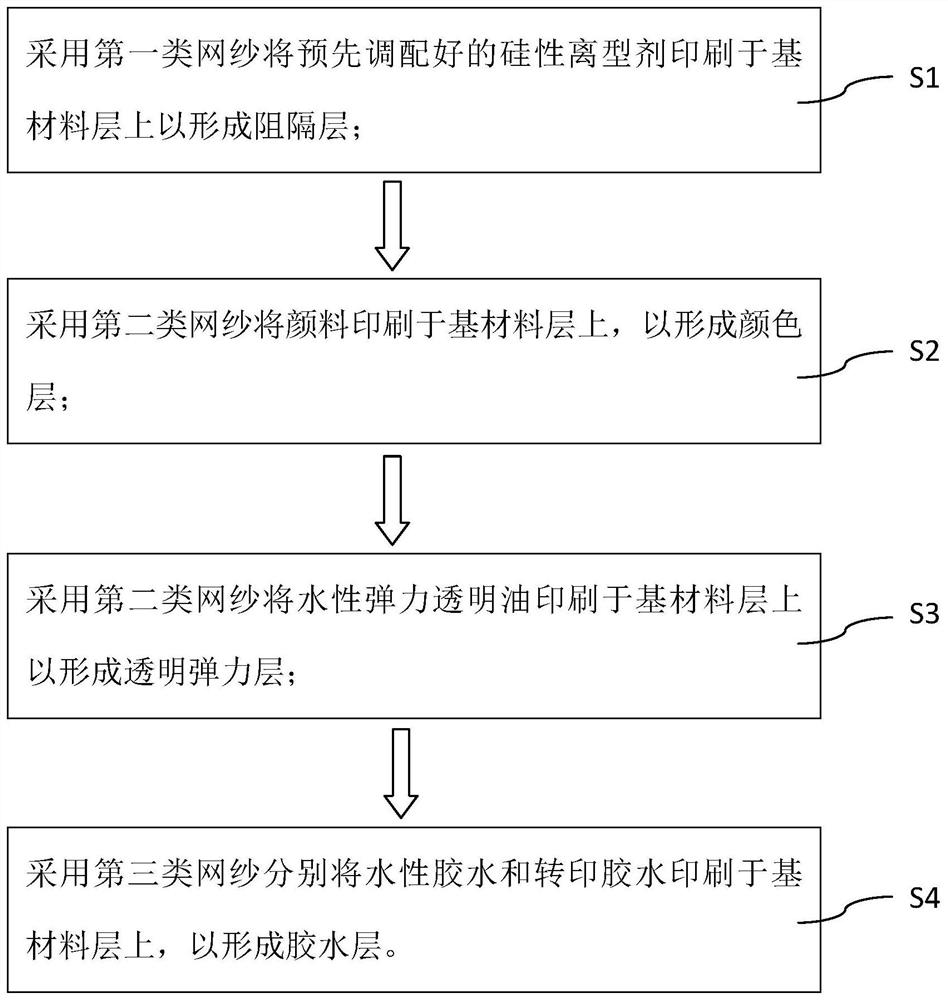

[0057] A heat transfer process, such as figure 2 As shown, it specifically includes the following steps:

[0058] Step S1, using the first type of mesh to print the pre-prepared silicone release agent on a base material layer to form a barrier layer;

[0059]Step S2, using the second type of mesh to print the pigment on the base material layer to form a color layer;

[0060] Step S3, using the second type of mesh to print water-based elastic transparent oil on the base material layer to form a transparent elastic layer;

[0061] In step S4, the third type of mesh is used to print the water-based glue and the transfer glue on the base material layer to form a glue layer.

[0062] Specifically, first, the prepared silicone release agent is printed on the base material layer with 32-81T mesh gauze; after ink printing is completed, the pigment is printed on the base material layer with 32-120T mesh gauze, And repeat the printing twice; print the water-based transparent elastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com