Construction method of large cantilevered steel-concrete structure combined steel bar truss floor bearing plate

A technology of reinforced trusses and steel-concrete structures, which is applied to floors, building components, building structures, etc., can solve problems that affect the progress of the project, and achieve the effects of saving consumption, reducing a large amount of investment, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A construction method for a combined reinforced truss floor deck of a large cantilevered steel-concrete structure. The specific steps of the construction method for a combined reinforced truss floor deck of a large cantilevered steel-concrete structure are as follows:

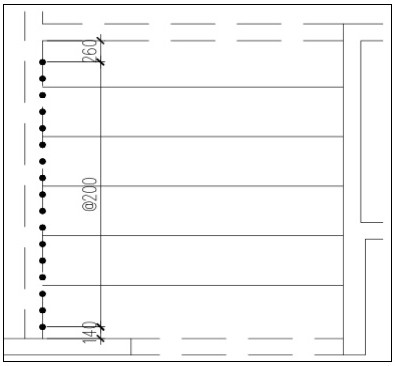

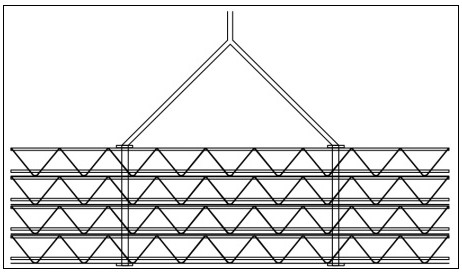

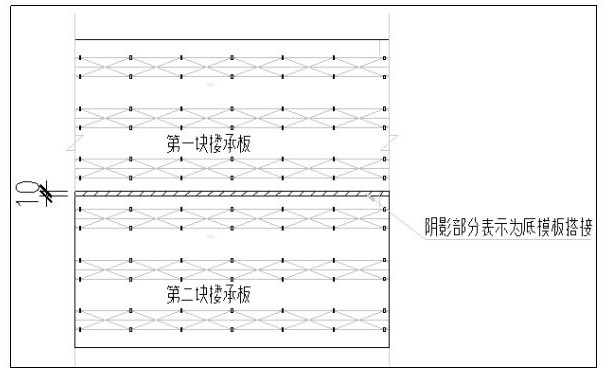

[0043] Step 1. Assemble the truss floor deck, assemble in strict accordance with the drawings, use special connectors to assemble the galvanized bottom formwork and steel truss on site, and the distance between each row of stressed hooks is 20cm; select the corresponding truss and bottom formwork for assembly , use connectors to fix the four corners to ensure the overall stability. During the subsequent installation of the fixing parts, the metal hook and the rotary wrench are connected by a roller to form a movable whole. And pass through and fasten the steel bar of the truss web, the hook is a shaped processing member, the inner diameter is the same as the diameter of the steel bar of the truss web, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com