Movable back-jacking device

A mobility and mobile base technology, which is applied in construction, building structure, and building material processing, can solve problems that affect construction safety, cumbersomeness, and inaccurate load divisions, and achieve significant cost reduction and efficiency increase. Achieve precise positioning and good benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

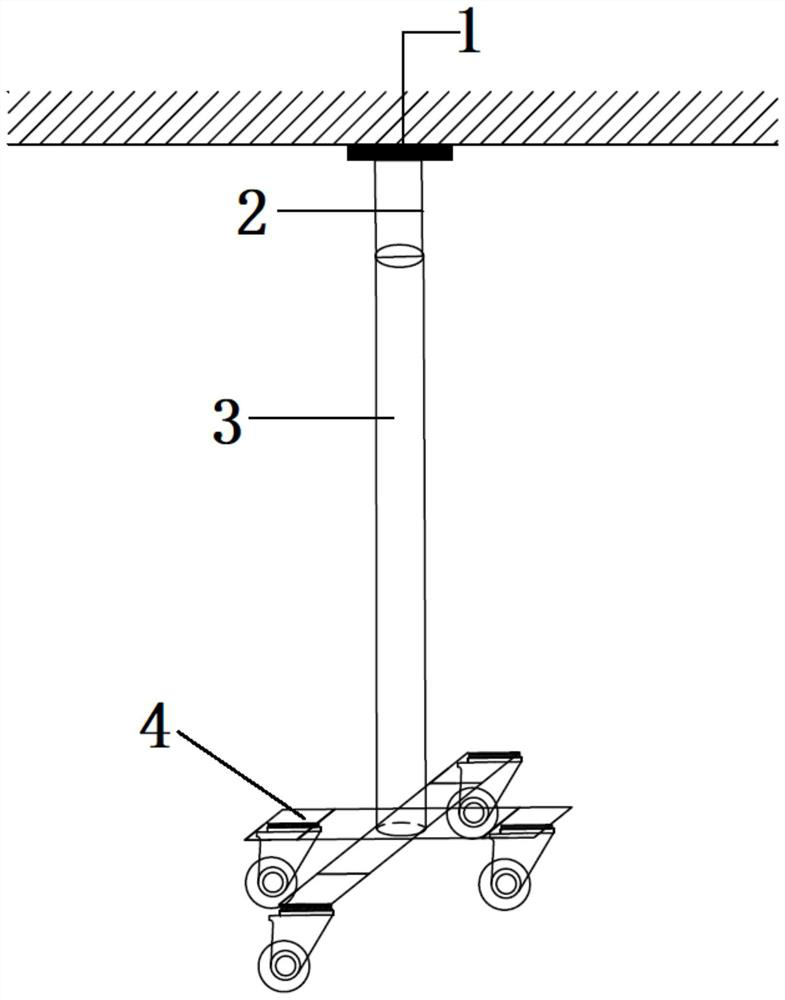

[0029] Embodiment 1: as figure 1 As shown, a movable jacking device includes a jacking plate 1, a hydraulic jacking device 2, a support member 3, and a movable base 4, and the jacking plate 1 is fixedly arranged on the top of the plunger of the hydraulic jacking device 2 , the hydraulic jacking device 2 is fixedly arranged on the top of the support 3 , and the bottom of the support 3 is arranged on the top of the movable base 4 .

Embodiment 2

[0030] Embodiment 2: as figure 1 , 2 As shown in and 6, a movable jacking device includes a jacking plate 1, a hydraulic jacking device 2, a support member 3, and a movable base 4, and the jacking plate 1 is fixedly arranged on the column of the hydraulic jacking device 2 The top of the plug, the hydraulic jacking device 2 is fixed on the top of the support 3, and the bottom of the support 3 is set on the top of the movable base 4;

[0031] The top surface of the plunger of the hydraulic jacking device 2 is fixedly connected to the bottom surface of the top strut 1 and the top surface of the plunger of the hydraulic jacking device 2 is located at the center of the bottom surface of the top strut 1;

[0032] The top of the support member 3 is fixedly provided with a fixed limiter 17 of the hydraulic jacking device, and the bottom of the hydraulic jacking device is arranged in the fixed limiter 17;

[0033] The fixed limiter 17 includes a fixed ring and a chassis, the chassis ...

Embodiment 3

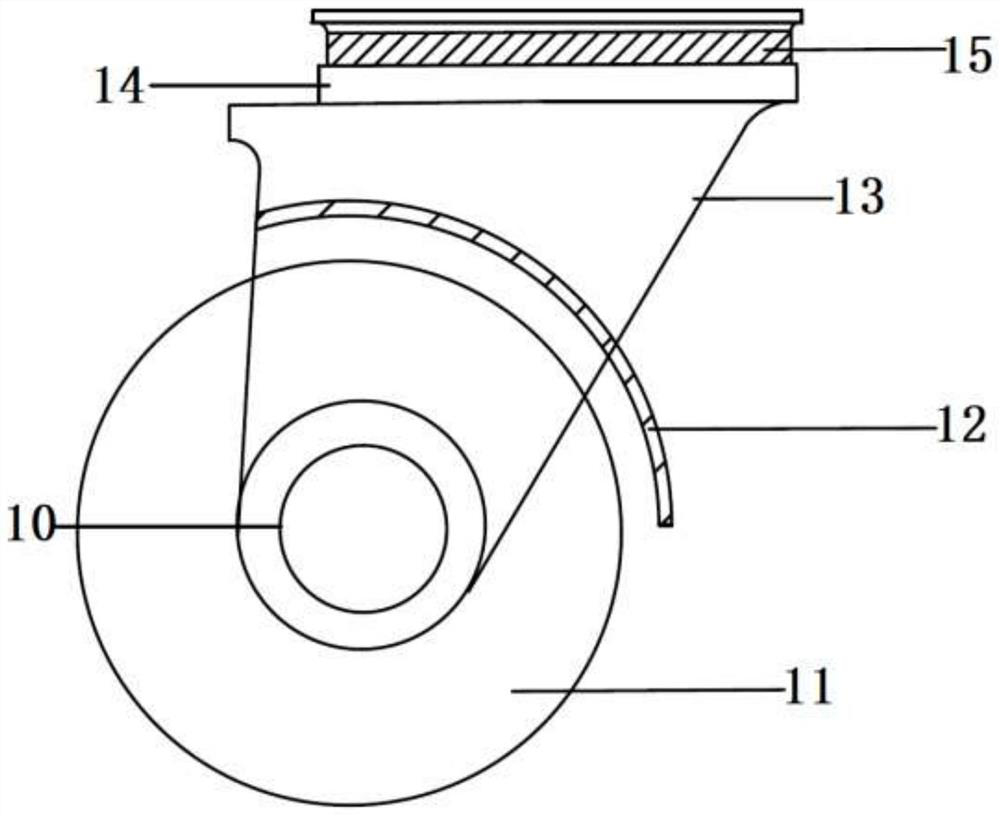

[0036] Embodiment 3: as Figure 1~6 As shown, the structure of the movable jacking device of this embodiment is basically the same as that of the movable jacking device of embodiment 2, the difference is that:

[0037] The distance between the bottom surface of the fixed ring and the bottom surface of the chassis is 2-3mm, and the inner diameter of the fixed ring is 2-3mm larger than the outer diameter of the hydraulic jacking device;

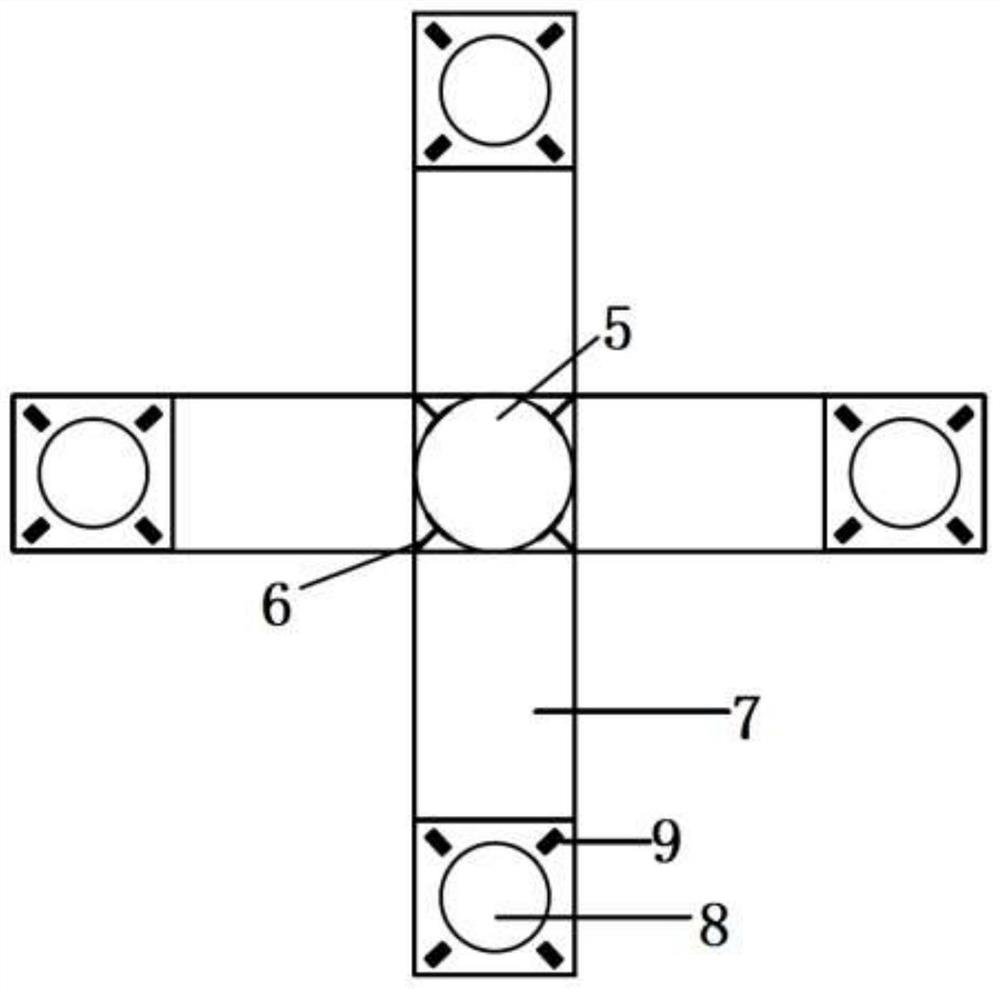

[0038] The inner edge of the limit chuck 5 is longer than the outer diameter of the support member 3, and the limit chuck 5 is evenly provided with several fixing members 6 of the support member 3, the fixing member 6 is perpendicular to the support member 3, and one end of the fixing member 6 In contact with the support member 3, the other end of the fixing member 6 extends to the outside of the limit chuck 5;

[0039] The side wall of the limit chuck 5 is uniformly provided with several through holes, and the hole wall is provided with equid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com